Section 3 • Scheduled Maintenance Procedures

Part No. 227656

GR-20J • GR-26J

3 - 27

September 2016

Checklist E Procedure

E-1

Test or Replace the Hydraulic Oil

Genie specifications require that this procedure be

performed every 2000 hours or every two years,

whichever comes first.

Replacement or testing of the hydraulic oil is

essential for good machine performance and

service life. Dirty oil may cause the machine to

perform poorly and continued use may cause

component damage. Extremely dirty conditions

may require oil changes to be performed more

often.

Before replacing the hydraulic oil, the oil may be

tested by an oil distributor for specific levels of

contamination to verify that changing the oil is

necessary.

If the hydraulic oil is not replaced at

the two year inspection, test the oil quarterly.

Replace the oil when it fails the test.

Note: Perform this procedure with the machine in

the stowed position.

1 Open the turntable covers of the machine.

2 Disconnect the battery pack from the machine.

Electrocution/burn hazard. Contact

with electrically charged circuits

could result in death or serious

injury. Remove all rings, watches

and other jewelry.

3 Remove the fasteners securing the chassis side

cover next to the tank to the chassis. Remove

the side cover. Lay the side cover and

fasteners to the side.

4 Place a suitable container under the hydraulic

tank.

Refer to Section 2,

Specifications.

5 Locate and remove the hydraulic tank filler cap.

Set the filler cap to the side.

6 Remove the drain plug and drain all of the oil

into a suitable container.

7 Clean up any oil that may have spilled. Properly

discard the used oil.

Note: To clean the inside of the hydraulic tank

using a mild solvent, it may be helpful to remove

the hydraulic power unit from the tank. Refer to

Repair Procedure 6-1,

How to Remove the

Function Pump.

8 Install the drain plug onto the hydraulic tank and

torque to specification.

Torque specification

Hydraulic tank drain plug

44 in-lbs

5 Nm

9 Fill the tank with hydraulic oil until the fluid is at

the full indicator on the hydraulic tank. Do not

overfill.

10 Install the filler cap onto the hydraulic tank, and

securely tighten. Do not over tighten.

11 Activate the pump to fill the hydraulic system

with oil and bleed the system of air.

Component damage hazard. The

pump can be damaged if operated

without oil. Be careful not to empty

the hydraulic tank while in the

process of filling the hydraulic

system. Do not allow the pump to

activate.

Содержание GR-26J

Страница 12: ...September2016 GR 20J GR 26J Part No 227656 This page intentionally left blank ...

Страница 75: ...Section 4 Repair Procedures Part No 227656 GR 20J GR 26J 4 29 September2016 This page intentionally left blank ...

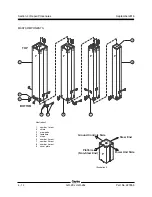

Страница 109: ...Section 6 Schematics Part No 227656 GR 20J GR 26J 6 3 September2016 ECM Pin out Legend ...

Страница 118: ...Section 6 Schematics 6 12 GR 20J GR 26J Part No 227656 September2016 This page intentionally left blank ...