17

Elite Steam

+03U221903

REV

2.

1

1

2

4

5

6

9

10

12

13

14

11

3

7

8

Fig. 4.a

IMPORTANT WARNINGS:

1.

Before star

ting, check that the humidifier is in pe

rfect condition, that there are no water

leaks and that the electrical pa

rts are dry;

2.

Do not connect p

o

wer if the humidifier is damaged

or e

ven pa

rtially wet!

When installation is completed, flush the supply pipe for around

1

0 minutes by piping water directly into

the drain, without sending it into the humidifier; this will eliminate

any scale or residues that may cause

foam when boiling.

4.1 St

artup Checklist

Before star

ting the humidifier, the foll

owing should be checked:

• Water is connected, the line has been flushed, and

external valves

are open.

• Drain is connected, run to an open drain, and has a trap under t

he unit.

• Electricity is connected in accordance with instructions, local codes and data labels in the unit.

• The p

ower fuses are installed and intact.

• All control wiring is done and tested.

• Airfl

o

w switch is wired to open on air fl

ow loss.

• Hi-limit humidistat is wired to open on humidity rise above set p

oint.

• Unit wires have been checked to make sure they and all connect

ors are tight from shipping.

• The steam hose(s) are run correctly with no s

ags or kinks and sloped properly according

to the manual.

• Conden

sate hoses are run correctly with no sags or kinks and s

loped properly according to the manual.

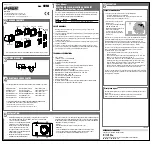

4.2 The Elite Steam Controller

The Elite Steam controller features a comprehen

sive information

display that sh

ows the

operation of the system at a glance:

1

Display is % of nominal capacity

2

Maintenance

3

Display is amperage (default)

4

Steam is being produced

5

Cylinder filling

6

Foaming

7

Water presence inside the

cylinder

8

Cylinder draining

9

LE

Ds indicate: p

ower (yello

w), operation (green) and al

arms (red)

10

Drain button for manual draining of c

ylinder and confirmi

n

g parameter values

11

ON/OFF button

12

Reset button to reset alarms and access parameters

13

Le

vel of output: 33%,

6

6%,

1

00%

14

Fan relay is activated

4.3 Starting Elite Steam

• Insure that the ex

ternal p

ower is turned on.

• Push the top pa

r

t of the On/Off button so that the I pa

rt is in. The yellow Power

LE

D will be lit. The Elite Steam is now ready to operate.

The Elite Steam is no

w ready to operate.

• When there is a call for humidity, Elite Steam will close its p

ower relays and send

p

o

wer to the electrodes in the plastic steam generator. The gr

e

en Operation

LED will light, indicating that operation has begun.

4.4 Starting with a new cylinder

When starting with a new cylinder, you should activate the cylinder cleaning function as follows:

1. Switch Elite Steam off.

n

o

k

c

a

b

m

a

e

t

S

e

ti

l

E

h

c

ti

w

s

d

n

a

,

”

n

i

a

r

d

“

d

n

a

”

t

e

s

e

r

“

s

n

o

tt

u

b

h

t

o

b

d

l

o

h

d

n

a

s

s

e

r

P

.

2

When the wrench blinks

then release the two buttons.

3. Press and hold "reset" until display shows 04.

.

WARNING:

DO

NO

T confirm any value higher than 04. In case, press “reset” until the

4. Press “drain” (minimum 1 second): the cleaning starts.

During the cleaning, the electrodes are p

o

wered and water is filled

in until it touches the

high-le

vel sensor or the phase current equals 20A, whichever occ

urs first. After either

(the drain valve and the drain tempering valve are activated for 3

minutes). Warming the

filling water helps

washing out any mold release or dirt. General Filters

,

Inc. recommends to

duty. When starting the unit with a ne

w or empty

c

ylinder, it may take a significant amount of time (hours)

for the unit to build up enough mineral concentration to reach rated capacit

y. This time can be shortened

by the addition of Alka-Seltzer through the steam

outlet on top of the

cylinder.

4. START -UP

display goes back to the normal operating mode and restart from step.

of the events is detected, the boiler is fully discharged with the e

lectrodes un-powered

do two cleanings when starting a new boiler. After the cleaning ends, the humidifier starts the regular

Содержание Elite Steam DS15

Страница 1: ...Residential Steam Humidi ers User manual Elite Steam...

Страница 4: ...4 Elite Steam 03U221903 REV 2 1...

Страница 25: ...Elite Steam 03U221903 REV 2 1 25...

Страница 26: ...Elite Steam 03U221903 REV 2 1 NOTES 26...

Страница 27: ...Elite Steam 03U221903 REV 2 1 27...