- 15 -

INSTALLATION

5 - COMBUSTION PRODUCT FLUEING

The installer or client must ensure that

the flue system chosen complies with

local installation regulations.

For the installation of the combustion

product evacuation system, accesso-

ries or an authorized combustion prod-

uct system must be used and adapt to

the oil fired condensing boiler with a

sealed combustion system.

Whatever the type of connection :

To prevent any accidental leakage:

• Check that the air inlet and combus-

tion product extraction outlet tube

and bend joints are properly sealed

after mounting.

• ensure that tight sealing joints are

used.

• use the fastening collars or flanged

components to attach the piping se-

curely to the wall with a least 1 collar

per female adapter of each section of

piping.

• exclude imperatively any use of oil or

grease.

To make assembly easier, apply liquid

soap over 5 cm (0.03 ft)of the section of

the tube to be fitted.

The tubing connections are arranged so

that no condensate is retained and to

ensure that they are transferred up to

evacuation (descending slop of 3%

between the base of the flue and the boi-

ler).

.

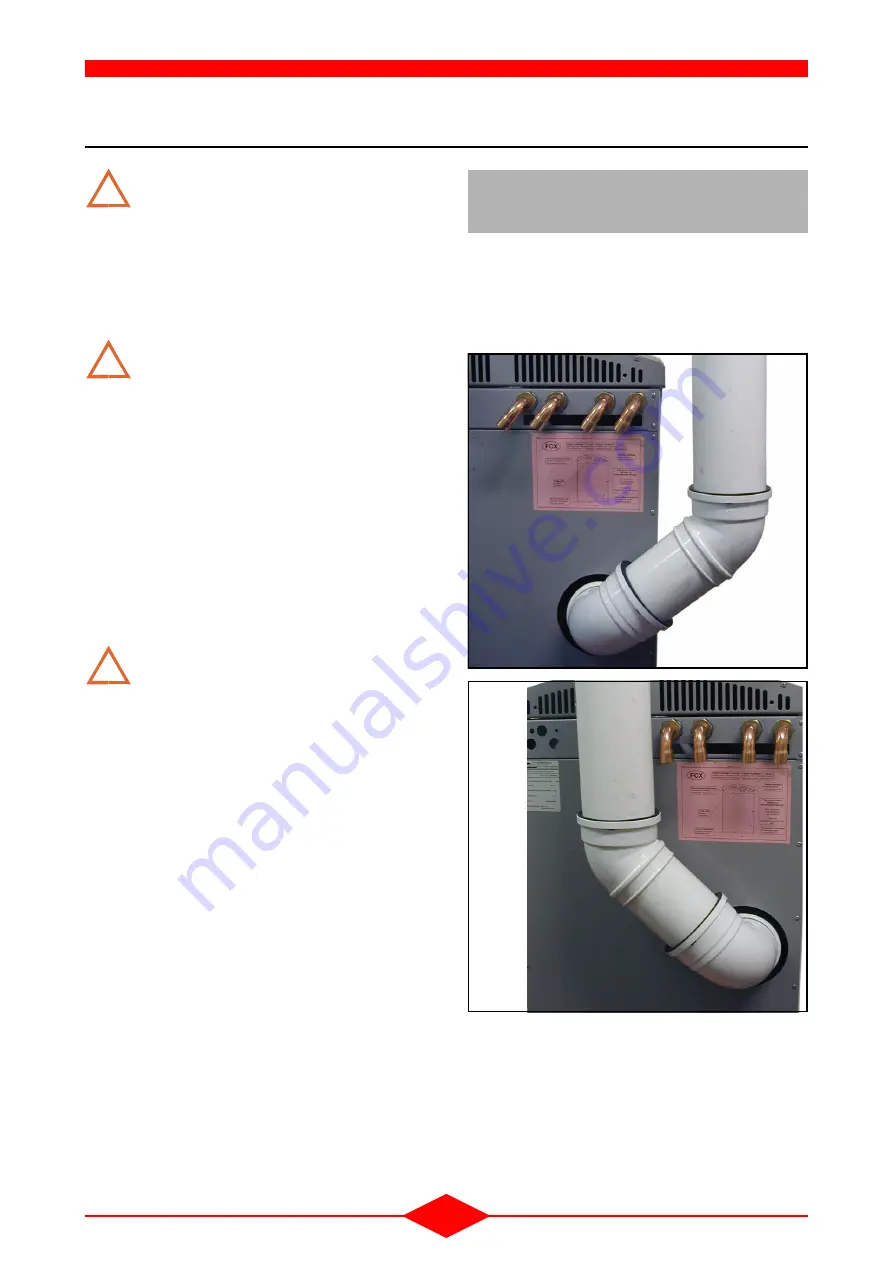

When the boiler must be placed as close as possible

to the rear wall, several configurations can be envi-

saged depending on the hydraulic connection - refer

to some examples below.

5.1.1 - Installation example

!

!

!

5.1 - Boiler placement according to the

combustion products outlet system

and to the hydraulic connection