•

The concrete block should be set on firm footings or on a floor capable of

carrying the weight of the concrete block and capable of absorbing the free

forces and gas forces of the compressor during operation. The ground under

the concrete block should be horizontal and flat.

•

The top surface of the block should be level and even.

•

There should be sufficient free space around the block to install corkboard (or

similar).

•

The block should be provided with anchor bolt recesses or holes according to

the anchor bolt spacing as per package lay out drawing.

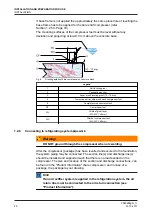

Fig.5

A

Chemical anchor

B

Grouted anchor, grounded to reinforcing steel

It is recommended to consult a concrete specialist/ constructor for the following

items:

•

The compound of the concrete with/without reinforcement.

•

The exact grouting depth (dependent on the soil conditions).

•

Installing foundation onto an existing floor, with sealing corkboard or vibration

isolators.

1.2.5.2 Anchoring

After the concrete block has cured the anchors should be installed as shown

above and in case of a package in accordance with the package lay out drawing.

Templates should be made to locate the anchor bolts or chemical anchors to

match the holes in the bottom flange of the base frame.

Grout the mortar according to the supplier instructions. Install chemical anchors

as illustrated in Figure 6, Page 18 and according to the instructions of the

anchor supplier.

INSTALLATION AND PREPARATION FOR USE

INSTALLATION

0089288gbr_11

30.10.2017

17

Содержание Grasso V 1100

Страница 6: ...0089288gbr_11 6 30 10 2017 ...

Страница 8: ...0089288gbr_11 8 30 10 2017 ...

Страница 10: ...0089288gbr_11 10 30 10 2017 ...

Страница 61: ...Fig 16 Grasso V 6 Pre lubrication valve APPENDIX Product Information PI 0089288gbr_11 30 10 2017 61 ...