9

BOILER OPERA

BOILER OPERA

BOILER OPERA

BOILER OPERA

BOILER OPERATION 3

TION 3

TION 3

TION 3

TION 3

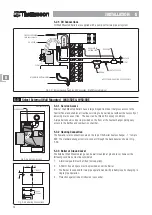

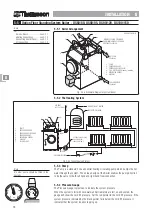

Fig. 3-3a Burner Reset Button

In the event of a ‘lockout’, wait 45 seconds and restart the Burner by pressing the Reset

button.

If lockouts are more than occasional, consult your service engineer as there may be a

fault with the fuel supply or Burner.

3-3.1 Restart Boiler after ‘Lockout’

Lockouts indicate a fault in the Boiler operation and can be attributed to:-

1. A fault in the electrical supply i.e. very low voltage.

2. An interruption in the fuel supply.

3. Faulty operation of the Burner or its safety control system.

4. A component failure.

5. A fault in heating system control external to Boiler.

Before attempting to restart the Boiler, remove the front panel of the Boiler and look for

any obvious problems i.e. oil leaks.

Restart Procedure:-

1. Check that there is sufficient oil in the tank and that the supply valves are open.

2. Check that the Boiler thermostat, time switch or programmer and any other system

controls are set to call for heat.

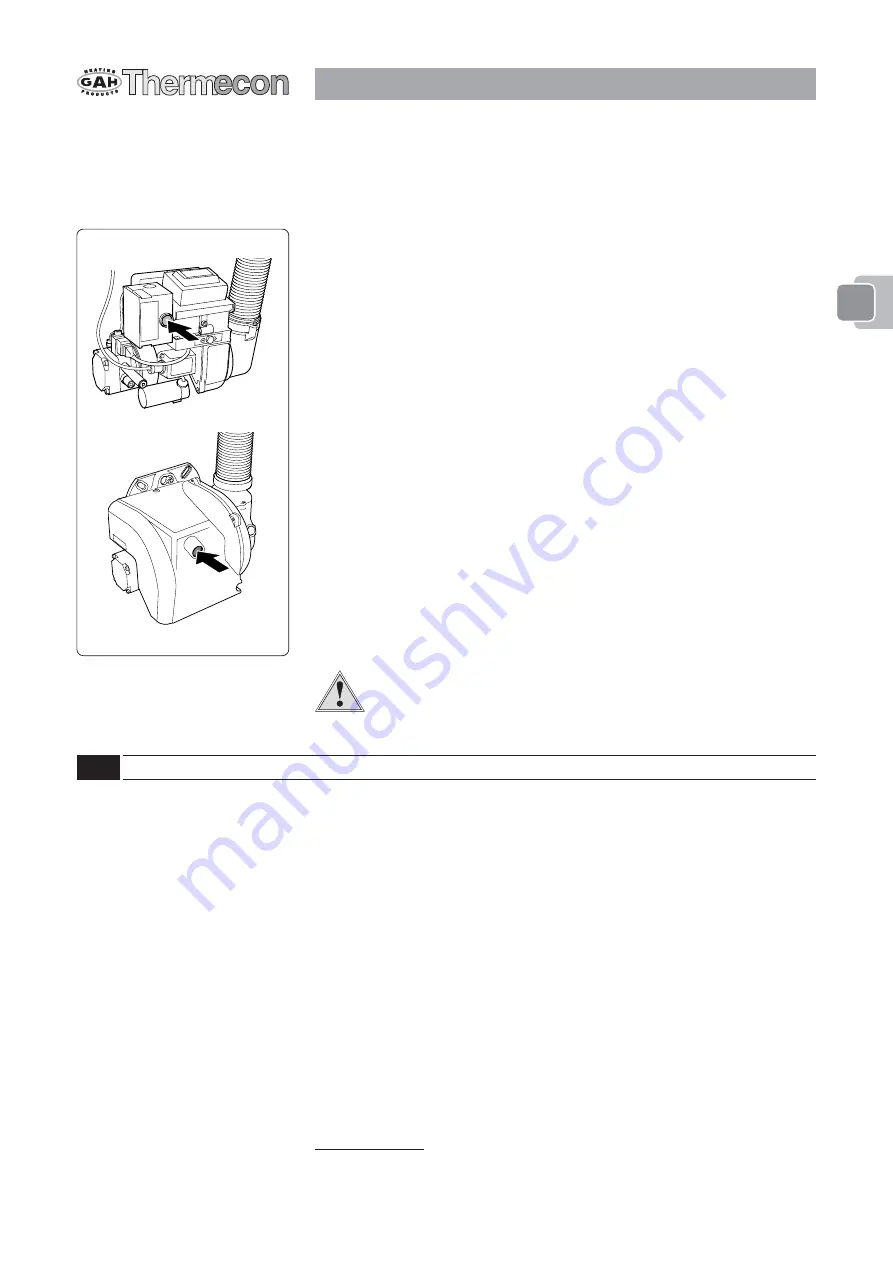

3. Press and release the red glowing plunger Reset button on the Burner control box.

The red light will extinguish and the Burner will commence the start sequence.

After 15 seconds, the Burner should fire normally.

If the Burner does not fire, the lockout symptoms will persist and the Burner control box

Reset button will again glow.

4. Wait at least 45 seconds and press the lockout button on the control box again.

IMPORTANT If the Boiler fails to start on the second attempt then:-

Switch off the Electricity Supply.

Refer to Section 12 Fault Finding.

DO NOT ATTEMPT TO START MORE THAN TWICE.

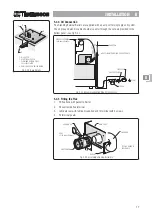

3-4

Care of the Boiler

3-4.1 All Internal Boilers

Occasionally wipe the casing down with a non-abrasive cleaner and vacuum out dust and

cobwebs from within the casing.

3-4.2 External Wall Mounted Boilers

Occasionally wipe the casing down with a non-abrasive cleaner and vacuum out dust and

cobwebs from within the casing.

Regular application of car polish to the outside of the casing will help protect the paint

finish and prevent algae growth.

3-4.3 Servicing

The Boiler requires regular servicing to ensure continued reliable operation and fuel

economy. Servicing at the stated intervals is a prerequisite of the Boiler Warranty.

A competent engineer should be sought to carry out the servicing at the required

intervals. An OFTEC trained and registered engineer would be a good choice.

SERVICE INTERVAL

FUEL - 28 Second Viscosity Class C Kerosene

- Service required once a year.

FUEL - 35 Second Viscosity Class D Heating Oil

- Service required twice a year.

33333