16

12/11 REV 4/22

GB743SHVT INSTALLATION TOOL SN# 1074 AND ABOVE

PLEASE CONTACT GAGE BILT FOR ALL OTHER SERIAL NUMBERS.

WARNING

:

Disconnect tool from its air source before disassembly.

OVERHAUL

1.

Remove nose assembly and adapter from tool before attempting disassembly of head cylinder assembly (743115).

2.

Remove end cap (743214).

3.

Push against threaded end of piston (743407) to slide it out of the head cylinder assembly (743115). Be careful not to damage

threads or cause burrs on polished piston rod surface.

The re

-

assembly sequence is the opposite of disassembly. (See Filling and Bleeding procedures pgs. 11

-

12). Apply Loctite® #242

and torque the button head cap screws (402479) uniformly to 40 inch lbs. (4.52 Nm) to prevent leakage around the gasket (704129).

HEAD

HANDLE

To inspect air cylinder bore, remove base cover (744124). Any further disassembly will require removal of the manifold

-

handle (744303) first.

For complete disassembly.

1.

Remove base cover (744124).

2.

Holding tool upright, remove four screws (A

-

928) and lift manifold

-

handle (744303) from handle assembly (744129) and set aside o'ring

(S832) and gasket (704129).

3.

Empty all hydraulic oil into an approved container and dispose of in accordance with the material safety data sheet.

4.

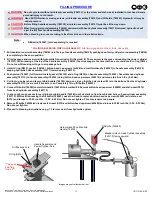

Place piston rod wrench assembly (704149) down into top of power cylinder (743131) and into the hex of piston rod assembly (744136).

While holding the piston rod wrench assembly (704149), remove flexlock nut (400559) using a 7/16" socket wrench or an adjustable

wrench. Still holding piston rod wrench assembly (704149), remove air piston assembly (744121) using packing plug wrench assembly

(704150), by turning counterclockwise.

5.

When air piston assembly (744121) is completely free from piston rod assembly (744136), tap or push on the piston rod wrench to eject

air piston assembly (744121) from bottom of handle assembly (744129).

6.

After removal of air piston assembly (744121), slide piston rod assembly (744136) back up to the end of its travel. Using packing plug

wrench assembly (704150) remove packing plug (744118).

7.

With packing plug (744118) removed, power cylinder (743131) can be removed by pushing on power cylinder tool assembly (704151)

when inserted into top of power cylinder (743131).

To reassemble the handle assembly (744129).

1.

Reverse the above procedure, being certain that all o'rings are properly lubricated before installation. Torque packing plug (744118)

to 45 foot lbs. (61 Nm).

2.

Attach the seal guide (704152) to the piston rod assembly (744136) and tap the piston rod assembly (744136) through the packing plug

(744118).

3.

Attach air piston assembly (744121) and flexlock nut (400559). Torque flexlock nut to 40 inch lbs. (4.52 Nm).

4.

Attach air piston assembly (744121) to piston rod assembly (744136).

5.

With the piston rod in the down position, fill oil passage on top of handle assembly (744129) with automatic transmission oil, Dexron® III or

equivalent. When looking at top of handle assembly (744129) the oil passage is the hole that has a counterbore for (S832) o'ring.

6.

Replace gasket (704129) and o'ring (S832), just prior to replacing manifold

-

handle (744303). Torque all screws to manual specifications.

(See Filling & Bleeding procedures pgs. 11

-

12) & (See torque specs. pg. 10).

AIR VALVE

1.

Remove pin (744149) and muffler (744143).

2.

Insert valve extractor (S1178) into end of valve plug (744142) and pull it out.

3.

Using the same procedure, pull out valve spool assembly (743142).

4.

It should never be necessary to remove valve sleeve (743144) unless the ports in the valve sleeve (743144) are plugged from

contaminated air. If ports are plugged, use needle nose pliers to grasp end of spring (744144), turning clockwise and pulling to

dislodge from groove in casting. Valve spring installation tool (744251) will facilitate the proper installation of the spring (744144).

5.

Valve sleeve (743144) can be pulled out using valve sleeve removal tool (744152).