English

CCD-0005506 Rev: 08-16-22

- 8 -

WARNING

●

DO NOT use matches, candles or other sources of ignition

when checking for gas leaks.

●

Do not smoke while leak testing.

●

Never leak test with an open flame.

Please follow below steps to make leak test for the appliance:

1.

Extinguish all open flames.

2. Turn the gas supply valve and control knobs off.

3. Prepare soap solution mixing of equal parts mild detergent or

liquid soap and water.

4. Spray the soap solution on all gas connections and gas pipes

of the appliance.

5. Turn the gas supply valve on and inspect all gas connections

for bubbles:

−

If no bubbles appeared, there is no gas leak in the

appliance

−

If bubbles appeared, where there are bubbles, where there

is a leak point.

6. If a gas leak is detected, tighten the connection and repeat the

above steps. If the leak is on the gas supply line connection,

replace the gas supply line and repeat above steps.

NOTE:

It is also recommended that you perform a leak test at

least once a year whether the propane gas supply cylinder has

been disconnected or not.

Pressure Check

1.

Extinguish all open flames.

2. Turn the gas supply valve and control knobs off.

3. Remove the rear vent decoration panel if the rear vent

decoration panel has been installed.

(

NOTE:

See Rear Decorative Panel installation section for

screw locations.)

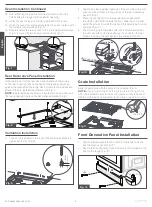

4. Remove the Screw with the sealing gasket from the pressure

test port on the range. (Fig. 5)

Fig. 5

5. Using the rubber tube from the pressure check measuring

device, slide the rubber tube down over the gas pressure test

port. The rubber tube should seal around the pressure test

port on the range.

6. Turn on the LP gas to the appliance.

7. The pressure gauge tester should measure between 10” WC

to 13.8” WC. (Fig. 6)

Fig. 6

8. Write down the pressure reading on the gauge and wait 5 min.

Recheck to see if the reading on the gauge has decreased.

If the gauge reading has decreased, there is a potential leak.

Please check the various gas connections using the bubble

test. If the leak can not be found, please consult with a service

professional and ensure the gas flow to the appliance is off.

9. Turn off the LP gas to the appliance.

10. Remove the rubber tube of the pressure check measuring

device.

11. Replace the screw with the gasket from step 2. Before

replacing the screw, inspect the rubber gasket seal for any

signs of damage. Replace seal if damaged.

12. Tighten the screw to 1.3 Nm to 1.7 Nm.

NOTE:

Ensure the product is gas leak checked after the pressure

check test is completed by also testing the pressure check port

screw. If any leaks are detected around the pressure check port

screw and gasket, a new one can be purchased. Call Furrion

support for a replacement.

Electrical Connection

WARNING

PRODUCT DAMAGE HAZARD

●

Connect to 12V DC service only.

●

Connect only to protected circuit fused for not more than 15

Amps.

●

DO NOT hi-pot range unless electronic ignition system has

been disconnected.

●

The power supply of this oven is 12V. Connect the components

below separately. (See Wiring Diagram)

NOTE:

Ensure to connect the wires with the correct polarity.

Red is “+” and Black is “-”.

●

12V power for:

Igniter, Oven Light, Cooling fan, Electronic

Timer & Display, 140

o

F (60

o

C) Thermostat Control.

−

Feed the cable through the electrical cord cutout on the

upper rear-right corner of the cabinet, use a 15A fuse at

the power source for protection.

−

The nameplate is located on the cavity frame (near the

door) of the oven, refer to the label for the technical

specifications.

Nameplate Positon

Wiring Diagram

Switch 6

Switch 5

S

wit

ch 4

S

wit

ch 3

S

wit

ch 2

S

wit

ch 1

DV12V+

DV12V-

Lighter

Ignition needle 1

Ignition needle 2

Ignition needle 3

Ignition needle 4

LED 1

Lamp

LED 2 LED 3 LED 4