VYPER

™

VARIABLE SPEED DRIVE

INSTALLATION

100-200 IOM (FEB 09)

Page 28

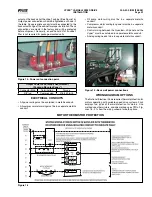

Figure 25 - Step 1, Removing the Pipe Plug

Figure 26 - Step 2, Connecting a Hose Fitting

Step 4:

Close the drain valve and refill the unit with Running

Coolant.

b. Verify power wiring has been connected at the correct

connection points and properly seated in accordance with

the engineering drawings for the specific installation.

c. Separate grounded metal conduits must be provided for

input power, output power, and control wiring. Failure to

provide separate conduits could result in disruption of

other electrical devices due to harmonics and REI/EMI

generated in the drive.

d. It is imperative that wiring from the drive to the motor

be enclosed in a grounded metal conduit even if poured

in a concrete floor. PVC conduit is not allowed.

e. Conduit should be bonded to the cabinet.

f. Use the conduit knockouts provided. Avoid metal shav-

ings in the drive enclosure.

g. Clean out all debris with a low power magnet or a

vacuum cleaner.

h. Protect signal wires from noise. Be sure to use shielded

and properly grounded control wires. Noisy input sig-

nals can cause erratic drive operation.

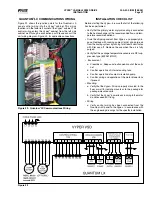

THREE INSTAllATION STEPS

Installation of the Vyper

™

can be done in a few easy steps.

Before beginning the Setup Procedures, be sure that the

cabinet has the proper electrical connections as discussed

in previous sections.

The Vyper

™

setup consists of three primary requirements:

• Cooling Loop Fluid Preparation

• Quantum

™

LX Panel Setup

• Job

FLA Trim Pot Adjustment.

COOlANT REPlACEMENT

AlWAYS WEAR EYE PROTECTION

WHEN SERVICING THE COOlING

CIRCUIT OF THE VYPER

™

.

The Vyper

™

is shipped from the factory with a premixed

shipping fluid which contains a rust inhibitor that prevents

corrosion of the internal cooling passages. The shipping

fluid also helps to keep the internal passages free from

contaminants.

Shipping fluid must be drained

from cooling loop at installation of

drive and replaced with run coolant.

Figure 24 shows the cooling circuit of a remote-mounted wa-

ter-cooled Vyper

™

. Coolant preparation for the Glycol-cooled

version is identical. The shipping fluid must be removed

from the cooling loop and replaced with Running coolant.

To replace the shipping fluid, the following steps need to be

performed:

Step 1:

(See Figure 25) Remove the pipe plug from the top

of the exit manifold with an adjustable wrench. This allows

air to enter the system and displace the fluid during the

draining cycle.

Step 2:

(See Figure 26) Connect a hose fitting to the drain

of the heat exchanger. Be sure that the hose is connected

tightly to the drain fitting so no fluid is spilled.

Step 3:

(See Figure 27) Open the drain valve and allow the

fluid to drain from the loop. Catch buckets should be able to

hold approximately 1½ to 2 gallons of liquid.

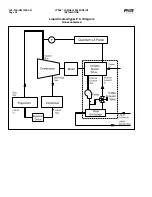

Figure 24 - Vyper

™

Coolant Circuit

Содержание Vyper 254

Страница 17: ...VYPER VARIABLE SPEED DRIVE INSTALLATION 100 200 IOM FEB 09 Page 17 Liquid Cooled Vyper P I Diagram Economized...

Страница 26: ...VYPER VARIABLE SPEED DRIVE INSTALLATION 100 200 IOM FEB 09 Page 26 ANALOG BOARD WIRING Figure 21...

Страница 67: ...100 200 IOM FEB 09 Page 67 VYPER VARIABLE SPEED DRIVE NOTES...