ZIPThaw™ 202 System User Manual

Fremon Scientific, Inc.

5726 La Jolla Blvd., Suite 304, La Jolla, CA 92037USA

P

age 16 of 43

FDA

CLEARED

ZipThaw

™

20 2 System

User Manual

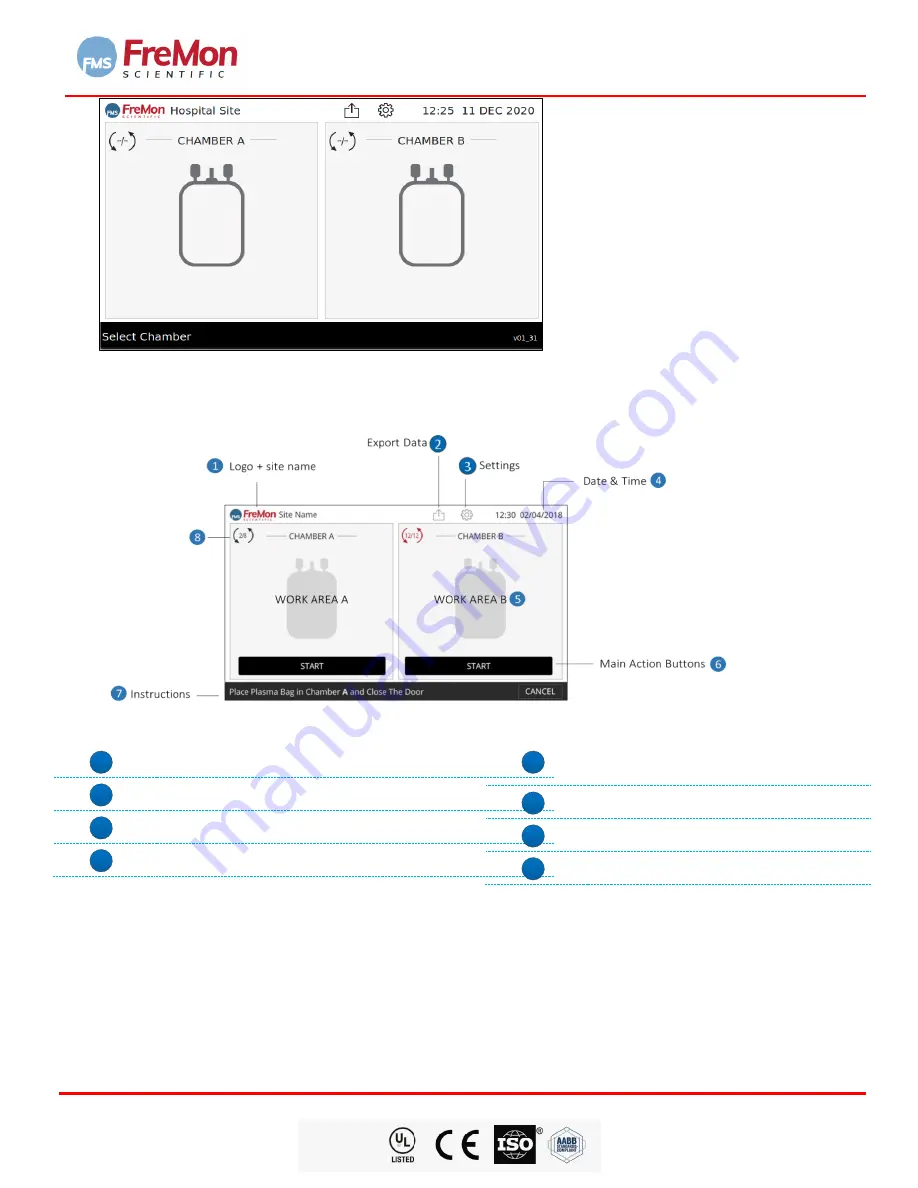

FIGURE 11. HOME SCREEN

7.4 MAIN SCREEN DESCRIPTION

FIGURE 12. Home Screen

1

FreMon logo+ site name

2

Export Data.

3

Settings.

4

Date & Time.

5

Work Area A+B - the user main area

interaction.

6

Main Action Buttons.

7

Instructions for active Chamber.

8

Number of ZipSleeve

TM

uses indicator.

7.5 SETTINGS

Pressing the “

Settings

”

icon will open the settings login screen.

The following screens are for the device

administrator and technical support use only.

Entering the

Settings Screen

requires an administrator password. The administrator will have a default password

(

45253

, factory default) that can be changed in the setting screen.