51-9

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

the air supply to the filter, which is connected to the

Logix 500 series positioner.

3. With a maximum supply pressure of 87 psi (6 bar)

a regulator is not required.

4. With an operating pressure of more than

87 psi (6 bar), a reducing regulator is required. The

flow capacity of the regulator must be larger than

the air consumption of the positioner (4.12 scfm @

87 psi / 7 Nm

3

/hr @ 6 bar).

5. Connect the outlet connector Y of the positioner to

the actuator with tubing, independent of the action

(direct or reverse).

Wiring and Grounding Guidelines

Electrical connections: signal cable with cable passage

(NPT, PG13.5, or M20 x 1.5) to terminals 2 x 2.5 mm

Input signal: 4 – 20 mA, 4 – 12 mA, 12 – 20 mA

NOTE: Observe the minimum requirements of voltage

and equivalent electrical load: 12.0 VDC / 600

Ω

/ at

20 mA.

The performance is ensured only for a minimum input

current of 3.6 mA.

For wiring, the following notes should be observed:

NOTE: The input loop current signal to the Logix 500

should be in shielded cable. Shields must be tied to a

ground at only one end of the cable to provide a place

for environmental electrical noise to be removed from

the cable. In general, shield wire should be connected

at the source. (Figure 8)

Connect the 4-20 mA current source to ter11

and -12 (Figure 8).

Grounding Screw

The grounding screw, located inside the positioner

cover, should be used to provide the unit with an ad-

equate and reliable earth ground reference. This ground

should be tied to the same ground as the electrical con-

duit. Additionally, the electrical conduit should be earth

grounded at both ends of its run. The grounded screw

must not be used to terminate signal shield wires.

Compliance Voltage

(Figure 9)

Output compliance voltage refers to the voltage limit

the current source can provide. A current loop system

consists of the current source, wiring resistance, bar-

rier resistance (if present), and the Logix 500 imped-

ance. The Logix 500 requires that the current loop

system allow for a 12.0 VDC drop across the positioner

at maximum loop current.

CAUTION: Never connect a voltage source directly

across the positioner terminals. This could cause

permanent circuit board damage.

In order to determine if the loop will support the Logix

500, perform the following calculation.

Voltage = Compliance Voltage (@Current

MAX

)

- Current

MAX

*(R

barrier

+ R

wire

)

The calculated voltage must be greater than 12.0 VDC

in order to support the Logix 500.

Example: DCS Compliance Voltage = 19 V

R

barrier

= 300

Ω

(if present)

R

wire

= 25

Ω

CURRENT

MAX

= 20 mA

Voltage = 19 V - 0.020 A*(300

Ω

+ 25

Ω)

= 12.5 V

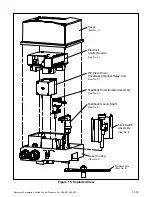

Figure 8: Wiring Diagram

Connection

Description

+11

Input +

-12

Input -

+41*

Limit switch 1 +

-42*

Limit switch 1 -

+51*

Limit switch 2 +

-52*

Limit switch 2 -

Y

Pneumatic output signal (outlet)

Z

Air supply (inlet)

*

= Optional connection

Table 8: Connection Table

PIEZO

RELAY

POT.

LS1

LS2

Internal

Housing

EARTH

Terminal

External Housing

Limit Switch 1

Limit Switch2

4-20 mA

Signal

Connect Shield at

Source Ground

-

+

4-20 mA Current Source

Shielded

Cable

Y

Z