51-16

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

HART 275 HANDHELD COMMUNICATOR

AND SOFTTOOLS CONFIGURATION AND

DIAGNOSTIC SOFTWARE

The Logix 520 supports and is supported by the HART

275 Handheld Communicator. The DD and the manu-

als listed below can be obtained from the HART

Communication Foundation or from your Flowserve rep-

resentative. For more information please see the fol-

lowing guides:

•

Product Manual for the HART Communicator

•

Logix 520 Digital Positioner with HART 275

Communicator User Guide

Flowserve corporation has written custom configura-

tion and diagnostic software for the Logix 500 series

called SoftTools™. This software and the

SoftTools

Quick Start Guide are available from a Flowserve rep-

resentative.

LIMIT SWITCH UNIT (Optional)

CAUTION: The installation of explosion proof elec-

trical equipment must comply with the procedures

contained in the certificates of conformance. Coun-

try specific regulations may apply. Electrical safety

is determined only by the power supply device

(Positioner operation with limited voltage only).

General

The Logix 500 digital positioner can be equipped with

an additional limit switch unit, designed as a two-wire

sensor in accordance with NAMUR. The low voltage

and current characteristics of these sensors allows

operation in hazardous areas.

Model Selection

To select the suitable Logix 500 version see product

information.

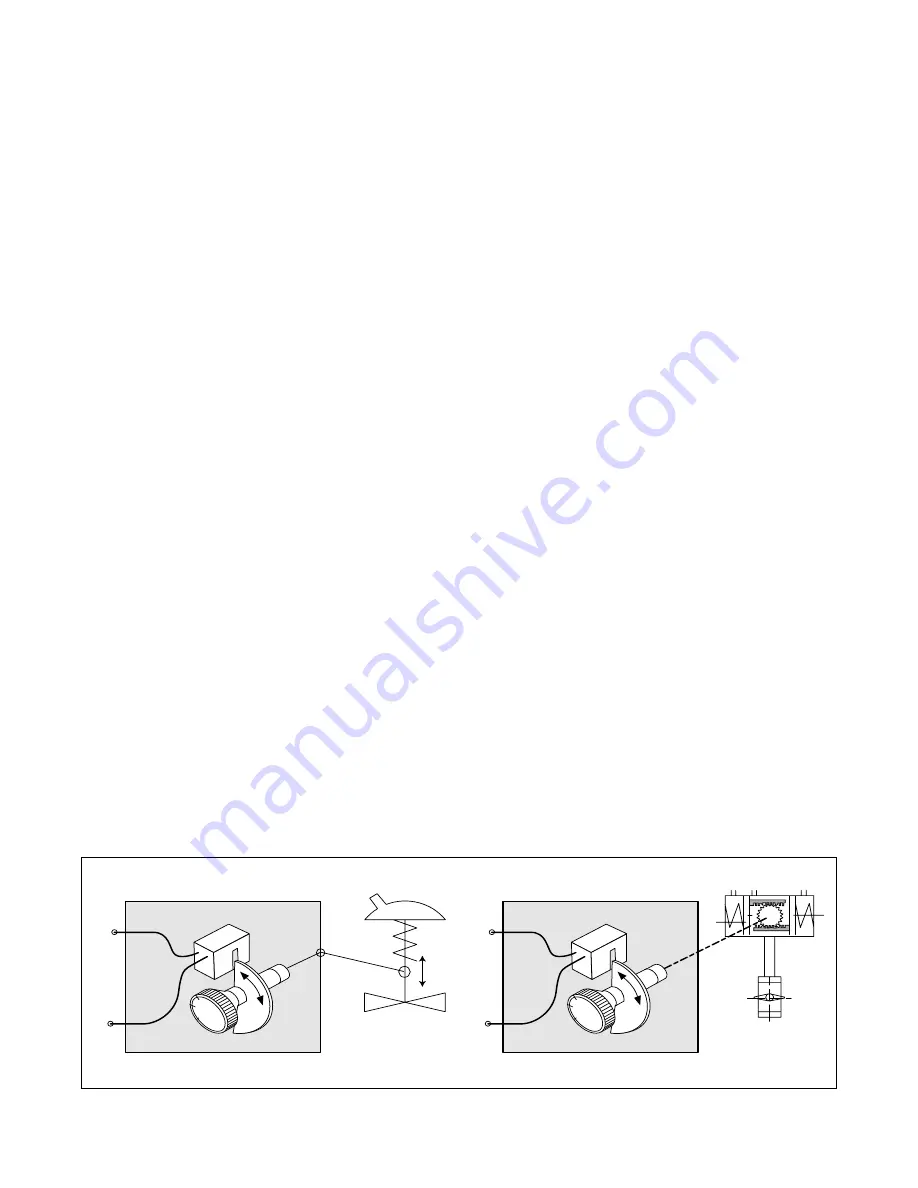

Principle of operation

The stroke of the diaphragm actuator or the rotary angle

of the rotary valve actuator is picked up by a stroke

lever or by a coupling at the actuator connection. The

lever/coupling moves the vane into the slot of the limit

switches LS1 or LS2 via shaft. The sensors are de-

signed as a proximity vane type switch. The switching

function is triggered if a ferromagnetic object (vane) is

inserted between the coils. The switching point can be

set by adjustment of the vane.

Installation

The limit switch unit is delivered already fitted to the

positioner and can not be retrofitted.

Start-up

After the Logix 500 digital positioner start-up in accor-

dance with the application is complete, the limit switch

unit can be adjusted and operation can be effected.

For adjustment remove the positioner cover. Figure 14

shows the maximum switching range of the limit

switches LS1 and LS2.

The switching points of the limit switches can be set by

an adjustment of the vane as follows (Figure 13):

1. Loosen the knurled screw (Figure 13) at the stroke

lever axis (1/2 to 1 rotations).

2. Move the positioner to the first switching position.

3. Set the switching point of the limit switch LS2 by

adjusting the vane of the lower switch. For adjust-

ment turn the corresponded slotted screw clock-

wise or counterclockwise.

4. Move the positioner to second switching position.

5. Set the switching point of the limit switch LS1 by

adjusting the vane of the upper switch. For adjust-

ment turn the corresponded slotted screw clock-

wise or counterclockwise.

6. Tighten the knurled screw.

7. Check the two switching points and repeat the

adjustment steps 1 to 6, if necessary.

Figure 12: Principle of Operation

Linear Version

Rotary Version

Rotary Valve Actuator

Limit Switch Unit

Limit Switch Unit

+

-

+

-

Diaphragm Actuator

Stroke

Lever

Butterfly Damper