7

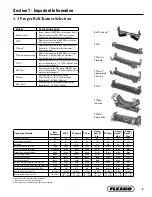

Section 4 - Installation Instructions

3. Adjust unit for conveyor width.

a. Measure the structure’s inside width from side to side.

b. Loosen the four jam nuts and set screws on the frames

and slide the unit apart to the same dimension as the inside

structure width measurement minus 1/2" (13mm) to ensure

an easy fit. Retighten set screws and jam nuts (Fig. 3).

NOTE: The inner tubes between the two frames should be

kept centered to ensure both sides have maximum support.

Center marks on the inner tubes make it easy to see that

the tubes are centered.

4. Mount unit on the conveyor.

Align the unit with the location marks on the structure.

NOTE: Check the slot adjustment range of the frame and

the mounting bracket (Fig. 4). If there is not 4" to 6" of slot

visible, turn the mounting brackets upside down for more slot

adjustment. Clamp or hold the unit in place, drill mounting

bolt holes on each side and secure with mounting bolts, lock

washers and nuts, or weld in place.

5. Adjust Positioner to the belt.

Loosen the two frame adjustment bolts on the side the belt is

running off and apply pressures as follows (Fig. 5):

a. Push down on unit until roller contacts 6" to 8" (150 to

200mm) of the belt. The roller on the other side should be set

to contact the belt 4" (100mm) or less. Tighten all nuts.

b. Allow the conveyor to run a minimum of five revolutions

and evaluate the results.

IMPORTANT: If more correction is needed, increase the

roller-to-belt contact pressure on the side running off; if

necessary, decrease contact pressure on the opposite side.

Fig. 3

Fig. 5

FRAME ADJUSTMENT

BOLTS

(on inside of bracket)

Loosen for Adjustment

MAINTENANCE

The rollers on the Positioner are sealed for life.

Center Mark

SET SCREWS

(2 on opposite side)

Fig. 4

Not enough adjustment

range in slot

Increased range of

slot adjustment

MOUNTING

BRACKET

(upside-down)

MOUNTING

BRACKET

(standard)

FRAME

FRAME

Structure

4.1 RBP1 Belt Positioner

Содержание RBP1

Страница 1: ...RBP1 Belt Positioner Installation Operation and Maintenance Manual www flexco com www flexco com ...

Страница 17: ...15 Section 8 Specs and CAD Drawings 8 2 CAD Drawing RBP1 Belt Positioner Small ...

Страница 18: ...16 RBP1 Belt Positioner Section 8 Specs and CAD Drawings 8 3 CAD Drawing RBP1 Belt Positioner Medium ...

Страница 19: ...17 Section 8 Specs and CAD Drawings 8 4 CAD Drawing RBP1 Belt Positioner Large ...

Страница 20: ...18 RBP1 Belt Positioner Section 8 Specs and CAD Drawings 8 5 CAD Drawing RBP1 Belt Positioner Extra Large ...

Страница 22: ......