19

18

SPECIALIZED

HEALTHY

AIR SOLUTIONS

SPECIALIZED

HEALTHY

AIR SOLUTIONS

OWNER’S MANUAL

OWNER’S MANUAL

ASCENDANT

™

ASCENDANT

™

SPECIALIZED

HEALTHY

AIR SOLUTIONS

OWNER’S MANUAL

TROUBLESHOOTING

A failure in the drive can fall into one of two categories,

ALARM

or

FAULT

.

WHEN THE DRIVE DETECTS A FAULT:

•

The digital operator displays text that indicates the

specific fault and the

ALM

indicator LED remains lit

until the fault is reset.

•

The fault interrupts drive output and the motor

coasts to a stop.

•

It will remain inoperable until that fault has been

reset.

TROUBLESHOOTING THE WHEEL

MOTOR VFD

Burner safeties consist of:

•

Low gas pressure switch (located on the entering

side of the dual automatic safety shutoff valve)

•

High gas pressure switch (located on the leaving

side of the dual automatic safety shutoff valve)

•

Automatic reset airflow switch (located inside the

unit measuring air pressure drop across the burner

profile plate)

•

High limit (controller mounted inside the burner

control panel)

•

Flame rod - signal can be measured at Honeywell

R7847A Flame Amplifier port provided on the

Honeywell RM7895A Flame Relay. The flame rod

signal is 0 – 5.0 VDC, with 1.25 VDC volts minimum

required. Refer to Honeywell literature for detailed

information.

If the FläktGroup SEMCO controller is calling for heat,

and all safeties are made, then 120VAC power will be

delivered to terminal # 7 on the Honeywell flame relay.

If 120VAC power is not present, then trace the voltage

using the SEMCO electrical schematic. If voltage is

present but the burner does not light:

•

Is there air in the gas line?

•

Are the gas valves opening?

•

Measure the flame amplifier signal

•

Is the flamerod clean?

If you have additional questions, please contact

FläktGroup SEMCO Service at (573) 443.3636.

TROUBLESHOOTING THE DIRECT-FIRED

GAS HEATER

(ON APPLICABLE UNITS)

The basic troubleshooting strategy is to determine if

the problem resides with the program, controller, input

devices, outputs, wiring, or controlled device.

Check sensor input values using the BACview keypad

to confirm that all inputs are operating correctly and

values are as anticipated.

View setpoints using the BACview setpoint menu.

Compare setpoints to the design performance shown in

the unit submittal.

View outputs using the BACview setpoint menu to view

the output determined by the controller.

Measure the output at the controller, then at controlled

device and compare to the output calculated by the

controller. Are all controller outputs set to automatic?

Are inverters set to

AUTO

and

NOT HAND MODE

?

The controller has hand-off-auto capabilities which

can be useful for troubleshooting or for emergency

operation. For automatic operation, all output switches

on the controller should be to the left.

Manuals for the inverters and any gas-fired equipment

are shipped with the unit. Manuals for damper

actuators are available from the manufacturer's web

site. Condensing units for DX coils are provided by

other than FläktGroup SEMCO.

WHEN THE DRIVE DETECTS AN ALARM (MINOR FAULT):

The digital operator displays text that indicates the

specific alarm or minor fault and the

ALM

indicator LED

flashes.

•

The motor does not stop.

•

The digital operator displays text that indicates the

specific alarm or minor fault and the

ALM

indicator

LED flashes.

•

Remove the cause of an alarm or minor fault to

automatically reset.

In the event of an alarm or fault consult the Yaskawa

V1000 Technical Manual (page 241), also available

at www.drives.com, or contact FläktGroup SEMCO

Technical Service at (573) 443.3636 for assistance.

SPECIALIZED

HEALTHY

AIR SOLUTIONS

OWNER’S MANUAL

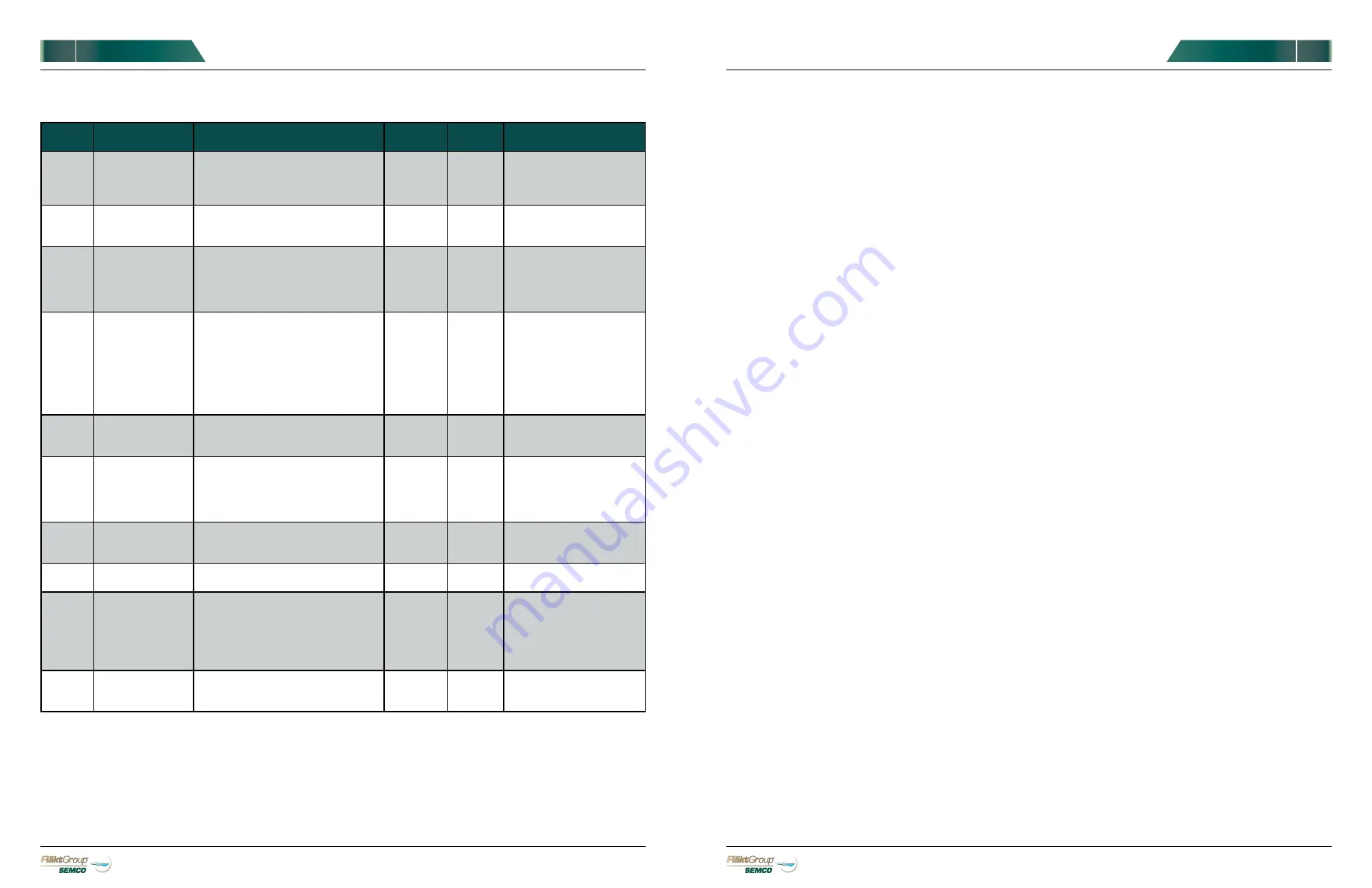

PARAM.

TITLE

FUNCTION

OPTIONS

DEFAULT

SETTING

SEMCO

SETTING

COMMENTS

H5-01

Drive Node

Address

0-20H

1F

*

Serial Communications

address

Set at factory. Consult

SEMCO

H5-09

CE Detection Time

0.0 - 10.0s

2

10

Sets the time required to

detect a communications

error.

L1-01

Motor Overload

Protection

0: Disabled

1: Std. Fan Cooled (speed range < 10:1)

2: Std. Blower Cooled (speed range

10:1)

3: Vector Motor (speed range 100:1)

1

3

Overload function based on

motor type

L2-01

Momentary Power

Loss Operation

Selection

0: Disabled - Drive trips on (Uv1) fault

when power is lost.

1: Power Loss Ride-Thru Time - Drive

restarts if power returns within the

time set in L2-02.

2: CPU Power Active - Drive will restart

if power returns as long as the CPU

is working.

0

1

Allows drive to restart after

power loss without a fault

L3-01

Stall Prevention

Level during

Acceleration

0: Disabled

1: Enabled

2: Intelligent Stall Prevention

1

0

Disables stall prevention

during acceleration

L3-04

Stall Prevention

Level during

Deceleration

0: Disabled

1: General Purpose Stall Prevention

2: Intelligent Stall Prevention

3: Stall Prevention with Braking Option

4: Over excitation Braking

1

0

Disables stall prevention

during deceleration

L3-05

Stall Prevention

Level during Run

0: Disabled

1: Decelerate Using C1-02

2: Decelerate Using C1-04

1

0

Disables stall prevention

during run

L5-01

Number of Auto

Restart Attempts

0 to 10

0

5

Selects number of automatic

restart attempts after fault.

L8-05

Input phase loss

protection

0: Disabled

1: Enabled

1

0

Selects the detection of

input current phase loss,

power supply voltage

imbalance, or main circuit

electrolytic capacitor

deterioration.

L8-07

Output phase loss

protection

0: Disabled

1: Enabled

2: Enabled

0,1

0

Selects the output Phase

loss detection