7

E

N

5.5 Cleaning the Filter

Clean or replace the filter whenever there is a

decrease in vacuum power.

Open the filter door on the rear of the vacuum

head.

Remove the filter and clean it with compressed air

and by shaking it or replace it if the filter material is

excessively dirty.

5.6 Stopping

The machine can be stopped by releasing the

lever on the rudder, which puts it into neutral.

When the ignition key is turned to OFF and

removed, the drive motor also stops.

WARNING

If none of the above actions stop the

machine, it can be halted by pressing the

red emergency button on the dashboard.

If the device is not to be used for some time, the

following steps should be taken:

-

Place the machine on a level surface;

-

Lock the drive by applying the parking

brake.

-

Check the battery connection cables

-

Turn the ignition key to OFF and remove it.

-

Clean the inside and outside of the

machine.

-

Store it in a sheltered and dry location.

-

Disconnect the battery.

-

Charge the battery about every 2 months.

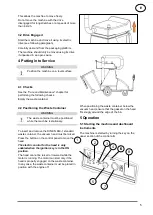

5.7 Transport

DANGER

Make allowance for the weight of the

machine during transport.

DANGER

For transport on vehicles, secure the

appliance in accordance with current

regulations so that it cannot slide or

overturn.

Ensure that the appliance is immobilised

by securing it with belts and ropes.

The ropes must pass through the tubes on

the machine chassis, which protrude from

beneath it.

Block the wheels with wedges.

The machine must not be lifted by means

of belts. For loading and unloading,

provide a ramp and use the drive of the

machine itself.

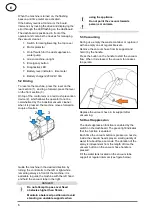

5.8 LED Diagnostics

The flashing code of the diagnostics LED on the

dashboard is as follows; count the number of

flashes until the first long pause. The flashing

stops when the cause of the alarm is removed or,

in certain cases, when the key is switched off and

on again.

No. of

flashes

Label

Description

1

Hardware

Fault in the

regulator