Fig. 7

1. Press in the plunger of the manual override with a blunt pin.

Ä

The solenoid valve switches.

2. Remove pin.

Ä

The plunger of the manual override is automatically reset. The solenoid

valve returns to the initial position.

9.3

Electrical manual override

9.4

Vacuum generator status indicator

LED

Status

Meaning

off

Switching point not reached

lights

Switching point is reached

Out

flashes

Teach procedure is started

off

Solenoid valve for vacuum is not switched,

vacuum is not generated

CE/CN/C-

PE

light on

Solenoid valve for vacuum is switched,

vacuum is generated

off

Solenoid valve for vacuum is not switched,

vacuum is generated

Vacuum

ON/OFF

OE/ON/O-

PE

lights

Solenoid valve for vacuum is switched,

vacuum is not generated

off

Solenoid valve for ejector pulse is not

switched, ejector pulse is not generated

Eject

lights

Solenoid valve for ejector pulse is

switched, an ejector pulse is generated

Tab. 14 Vacuum generator status indicator

10

Maintenance and care

Clean device

1. Switch off energy sources:

–

Operating voltage

–

Compressed air

2. Clean device with non-abrasive cleaning agents.

3. Check air filter through the display window for dirt.

Replace air filter

The air filter cannot be replaced in the vacuum generator OVEM-...-20/-30-C

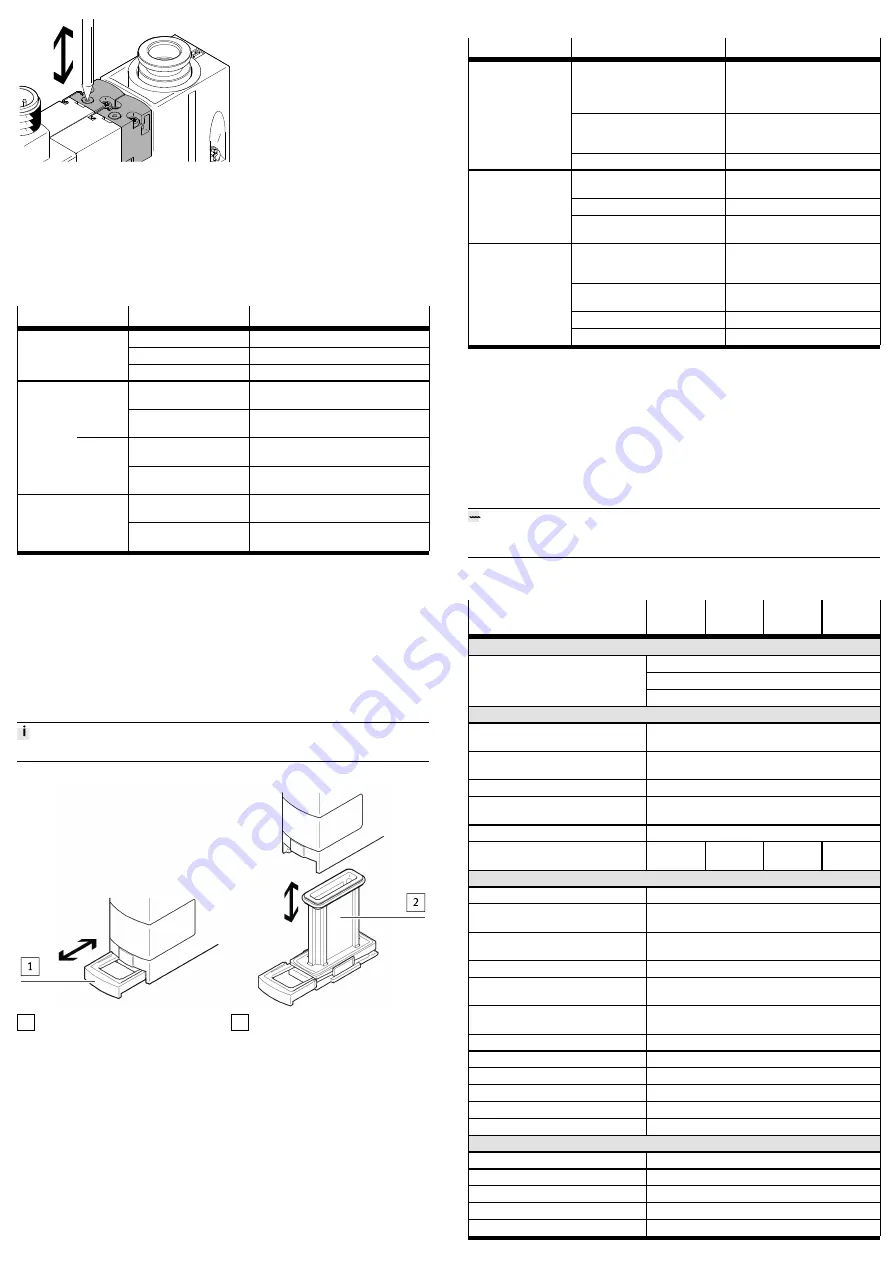

1 Gate valve

2 Filter

Fig. 8 Remove/install air filter

1. Exhaust the vacuum generator.

2. Carefully pull gate valve

1

out to the first detent. The gate valve must stay in

this position on the filter.

3. Pull filter

2

out. Clean with white spirit.

4. Push filter into the housing.

5. Push in gate valve.

Ä

The gate valve pushes the filter into the vacuum generator.

11

Fault clearance

11.1

Malfunctions

Malfunction

Possible cause

Remedy

device-independent vacuum

between workpiece and suction

gripper, ejector pulse not activated

or sufficiently dimensioned

–

Activate ejector pulse when

lifting the suction gripper.

–

Increase duration and intensity

of ejector pulse.

Tubing dimensioned incorrectly

–

Replace tubing (tubing dimen-

sions

è

Workpiece is not

released by the suction

gripper

Flow control screw closed

–

Open flow control screw.

Short circuit or overload at the out-

put

–

Eliminate short circuit/over-

load.

Device faulty

–

Replace device.

Switching output does

not react in accordance

with the settings

Incorrect switching point taught

(e.g. at 0 bar)

Repeat teach procedure

Operating voltage faulty

–

Apply permissible operating

voltage

è

Electrical connections swapped

–

Connect device correctly

è

No control signal

Check controller

No LED display for

switching inputs

Device faulty

–

Replace device.

Tab. 15 Malfunctions

12

Disassembly

1. Switch off energy sources:

–

Operating voltage

–

Compressed air

2. Disconnect pneumatic and electrical connections from the device.

3. Loosen mountings and remove device.

13

Disposal

ENVIRONMENT!

Send the packaging and product for environmentally sound recycling in accord-

ance with the current regulations

è

14

Technical data

OVEM-...

-05

-07/-10

-14/-20--

B/-BN

-20/-30--

C

General

c UL us - listed (OL)

RCM compliance mark

Approvals

KC mark

Characteristic values

Operating pressure OVEM-...-

QS/-GN/-PL

[bar]

2 … 6

Operating pressure OVEM-...-

QO/-GO/-PO

[bar]

2 … 8

Pressure measuring range

[bar]

–1 … 0

Overload pressure at vacuum

port

[bar]

£

5

Ready-state delay

[ms]

£

500

Dead time (evacuation and

ejection)

[ms]

£

12

£

22

£

35

£

60

Electronics

Nominal operating voltage

[V DC]

24 ± 15 %

Max. output current (per

switching output)

[mA]

100

Voltage drop (for all switch-

ing outputs)

[V]

£

1.5

No-load supply current

[mA]

<

70

Coil characteristics 24 V DC –

low current phase

[W]

0.3

Coil characteristics 24 V DC –

high current phase

[W]

2.55

Time until current reduction

[ms]

80

Capacitive load maximum DC

[mF]

£

100

Overload protection

Present

Inductive protective circuit

adapted to MZ, MY, ME coils

Insulation voltage

[V]

50

Surge resistance

[kV]

0.8

Max. current consumption

OVEM-...-1P/-1N

[mA]

180

without vacuum sensor

[mA]

30

Accuracy

[% FS]

± 0.5

Tolerance of fixed hysteresis

[% FS]

± 0.5

Short circuit current rating

Yes