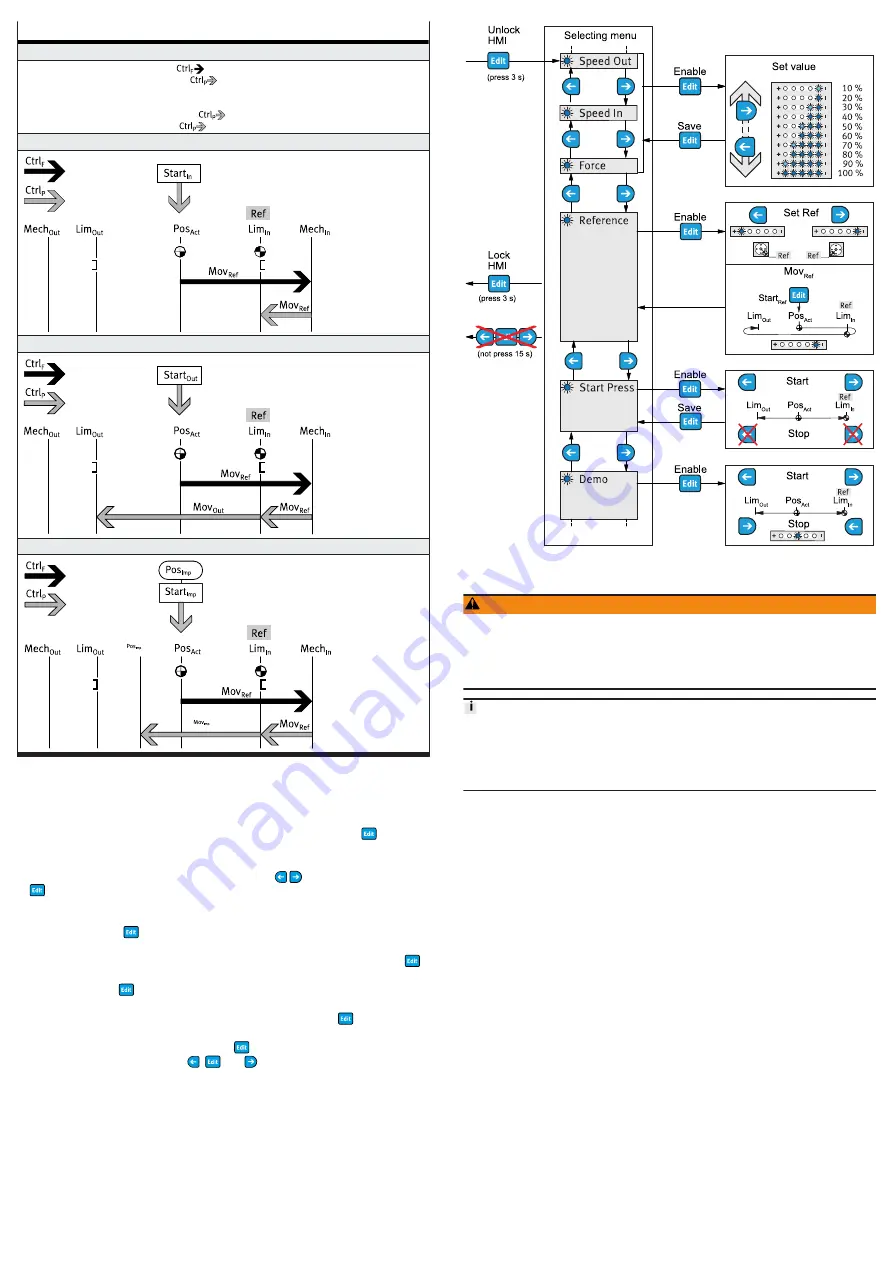

Homing after a restart as a function of the positioning task

Sequence

–

Mov

Ref

: force-controlled movement

against mechanical stop "Mech

In

"

–

Mov

Out

: position-controlled movement

to the reference end position "Ref"

–

Travel to the target position as a function of the positioning task

–

No travel, end position "Lim

In

" reached

–

Mov

Out

: position-controlled movement

to the end position Lim

Out

–

Mov

Imp

: position-controlled travel

to the intermediate position Lim

Imp

(IO-Link only)

Start

In

positioning task to the end position Lim

In

Start

Out

positioning task to the end position Lim

Out

Start

Imp

positioning task to the intermediate position Pos

Imp

(IO-Link only)

Tab. 9: Initialise restart sequence with reference end position "Ref"

9.4

Display and operating components (HMI)

The display and operating components (HMI) can be used to perform the fol-

lowing functions in the HMI menu:

–

Unlock pushbutton actuators (Unlock HMI), press and hold for 3 s

— an

active positioning task in DIO or IO-Link mode is stopped

(Condition for IO-Link operation: IO-Link parameter 0x000C.4 = false)

–

Select menu function with pushbutton actuators (selecting menu), press

–

Parameterise Speed Out, Speed In and Force setpoint values

(Set value: 10, 20, ..., 100% of the maximum value

save (Save), press

–

Parameterise the position of the reference end position "Ref" (Set Ref) and run

the referencing movement Mov

Ref

(Start

Ref

: Pos

Act

è

Lim

In

è

Lim

Out

), press

–

Run Start Press movement (Start/Stop) and save Start Press Position Pos

Start

Press

(Save), press

–

Execute demo run (Start/Stop)

–

Lock pushbutton actuators (Lock HMI), press and hold for 3 s

or no push-

button actuator input for 15 s

–

To acknowledge an error, press and hold

for 3 s

–

Reset to factory settings, press ,

and simultaneously for 10 s and then

carry out a Power OFF/ON on the logic power supply 24 V DC [pin 1].

Fig. 7: HMI menu

9.5

Homing with end position determination

WARNING

Risk of injury due to unexpected movement of components.

When starting the homing run, the drive is disconnected from the power supply

for a short time. This can cause unexpected movements of the connected

mechanics and crush parts of the body.

• Bring moving parts of the connected mechanical system into a safe position.

• Referencing with end position determination is only required again if the refer-

ence end position "Ref" or the useful range needs to be changed.

• During referencing with end position determination the intermediate position

Pos

Imp

and the start press position Pos

Start Press

is set equal to the new end

position Lim

Out

.

During referencing with end position determination the positions of the mechan-

ical stops Mech

In

/Mech

Out

are recorded in order to calculate the end positions

Lim

In

("Ref")/Lim

Out

for the dimension reference system.

Before running referencing with end position determination to a new reference

end position "Ref", the drive is de-energised for a required re-initialisation. Then

the power is restored and the process is started.