Translation of the original instructions

1

About this document

1.1

Applicable documents

All available documents for the product

è

Identifier

Contents

Application note

Application examples for connection and com

missioning

Tab. 1 Documentation for rotary gripper module

2

Safety

2.1

General safety instructions

–

Only use the product in original status without unauthorised modifications.

–

Only use the product if it is in perfect technical condition.

–

Observe labelling on the product.

–

Store the product in a cool, dry, UVprotected and corrosionprotected envir

onment. Ensure that storage times are kept to a minimum.

–

Prior to mounting, installation and maintenance work: Switch off power sup

ply and secure it from being switched back on.

–

Observe tightening torques. Unless otherwise specified, the tolerance

is ± 20 %.

2.2

Intended use

The intended use of the product is to grip, hold and rotate payloads (workpieces).

2.3

Foreseeable misuse

Gripping where the point of application is on the inside is not intended.

EHMD...GE: In normal operation, hitting the stop when moving in the opening

direction is not intended.

2.4

Training of qualified personnel

Only qualified personnel may perform installation, commissioning, maintenance

and disassembly of the product.

The qualified personnel must be familiar with the installation and operation of

electrical and pneumatic control systems.

3

Additional information

–

Accessories

è

4

Service

Contact your regional Festo contact person if you have technical questions

è

5

Product overview

5.1

Functional principle

Fig. 1 Functional principle

The product is a combined rotating and gripping module. Gripping occurs in the

closing direction of the gripper jaws (point of application on the outside).

The parallel gripper can be actuated electrically (EHMD...GE) or pneumatically

(EHMD...GP), depending on version.

In both versions, the parallel gripper can be continuously rotated by means of the

electric axis of rotation.

Gripping force backup

EHMD...GP: without gripping force backup. Backup for the gripping force can

only be ensured using additional measures (e.g. uninterruptible compressed air

supply).

EHMD...GE: with gripping force backup. If the power supply is interrupted, a min

imum gripping force is ensured by the mechanical design. However, the maximum

gripping force cannot be maintained.

5.2

Product design

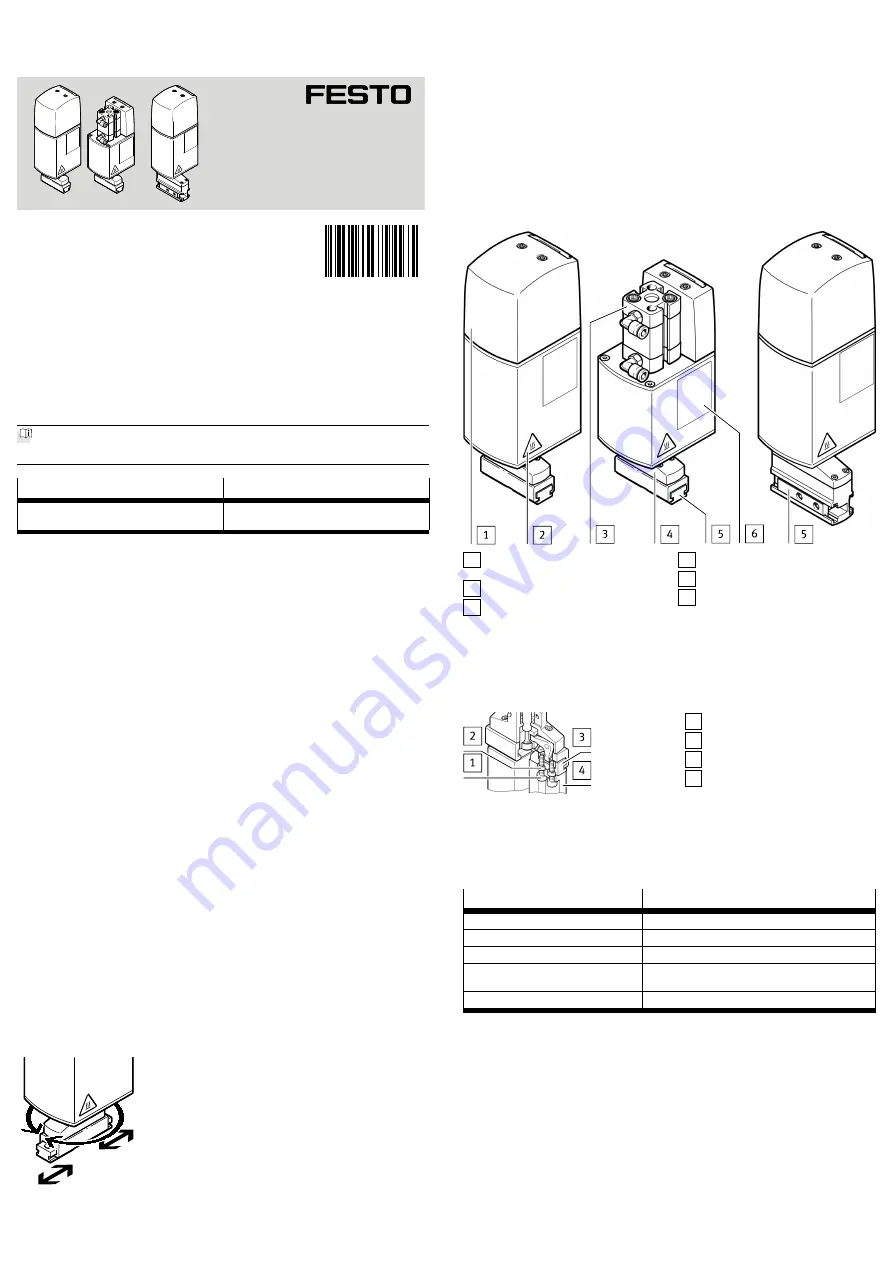

EHMD-40-RE-GE | EHMD-40-RE-GP | EHMD-40-RE-GE-16

1 Stepper motor for the gripper func

tion (installed in the housing)

2 Warning hot surface

3 Pneumatic cylinder for gripper

function

4 Rotatable gripper module

5 Gripper jaw

6 Product labelling

Fig. 2 Product design

6

Mounting

6.1

Mounting the gripper fingers (EHMD-40-RE-GE/-GP)

1 Screw

2 Centring sleeve

3 Gripper jaw

4 Gripper jaw blank (not in scope of

delivery)

Fig. 3 Mounting the gripper fingers

1. Press centring sleeves

2

into locating holes in the gripper jaws

3

.

2. Apply mediumstrength screw locking agent to socket head screws

1

.

3. Position gripper fingers

4

on the gripper jaws

3

.

4. Screw in socket head screws

1

. Comply with the tightening torque.

EHMD-40-RE-...

-GE/-GP

Centring hole

[mm]

5

H9

Centring sleeve

ZBH5

Threaded hole

M3

Max. screwin depth in grip

per jaw

[mm]

8.3

Tightening torque

[Nm]

1.2

Tab. 2 Mounting the gripper fingers

8108367

EHMD-40-RE-...

Rotary gripper module

8108367

201906a

[8108369]

Instructions | Use

Festo

SE

& Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 3470

www.festo.com