DHTG

Festo – DHTG – 2018-02e English

15

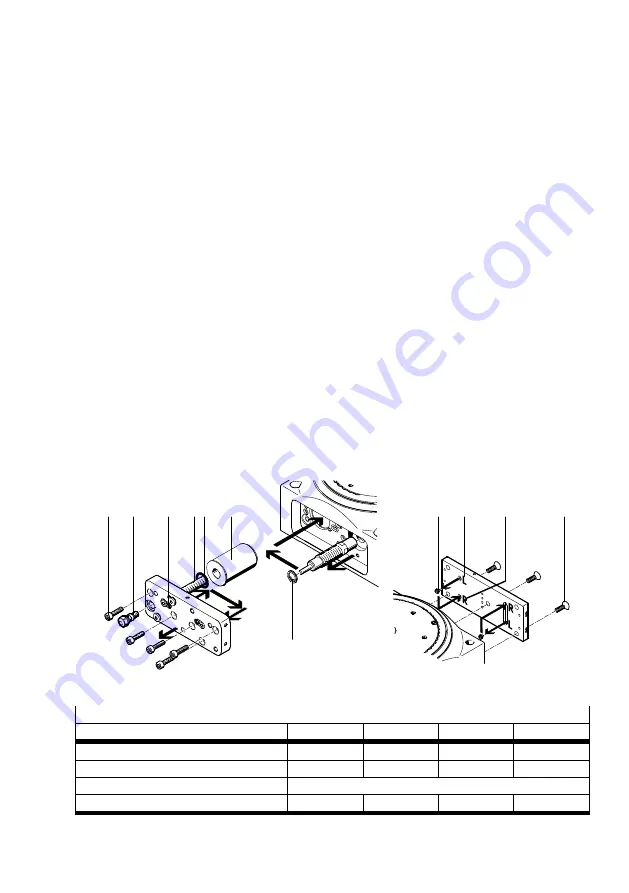

Conversion from clockwise rotation (as supplied) to anti-clockwise rotation:

1. Loosen the clamping element (K) of the adjusting screw one rotation.

2. Unscrew the adjusting screw

6

a few rotations.

3. Unscrew flow control screw

aJ

and the fastening screws (M) from the sub-base.

4. Using pliers, remove the retaining ring (S) on the shock absorber.

5. Fit the following:

–

the shock absorber with the retaining ring in the adjacent hole

–

the O-ring (P) / buffer (for DHTG-65) in the adjacent groove

–

the distance piece (T) in the same hole (distance piece omitted for 2/3 index stations)

–

the sub-base with the fastening screws and the flow control screw in reverse sequence

(tightening torque

è

6. Unscrew the fastening screws (N) on the stop plate.

7. Unscrew:

–

both locking screws (O) on the rear of the stop plate to begin with,

–

then screw them in again into the open holes (tightening torque

è

The open holes

(R) or (L)

in Fig. 14 determine the direction of rotation

(Holes (R) open: clockwise rotation).

8. Screw the fastening screws (N) on the stop plate again (tightening torque

è

The rotary indexing table remains pneumatically controlled as before.

9. Screw in the adjusting screw

6

until the desired cushioning is achieved

è

10.Tighten the clamping element (K) of the adjusting screw (tightening torque

è

(M)

aJ

(N)

(O)

(P)

(K)

(L)

(R)

(T)

(S)

6

Fig. 14

Tightening torque

Size

65

90

140

220

Flow control screw

aJ

[Nm]

1.5

1.5

5.5

5.5

Fastening screws (M)

[Nm]

2.9

2.9

9.9

9.9

Plug screw (O)

[Nm]

0.5

Fastening screws (N)

[Nm]

1.5

2.9

5.9

5.9

Tab. 17