FCI Electronics

Manual Part No. 415988-001

Issued: (03/12/99)

Page 5 of 18

Rev. 05/18/06 EC V06-0481

Revision C

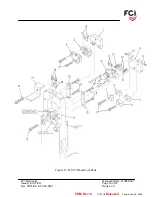

Principles of Operation

The lever attaches to the lower tooling and provides the mechanical advantage to generate the necessary

crimping pressure. As the lever is closed, a ratchet mechanism engages to prevent the lever from

opening until the crimping cycle is complete. When the lever is pulled closed, the lower tooling and

terminal are pushed up against the upper tooling. The crimp is formed between the wire and insulation

barrel anvils and the wire and insulation crimpers. Once closed, the ratchet releases and allows a spring

to pull the lever open.

Specifications

(See TA-75, TA-146)

When crimping the Mini PV™ to wires, the following parameters must be met.

Wire Length Requirements:

•

Minimum ……………………………………..19.05 mm (0.75 in.)

•

Maximum …………………………………….As Required

Insulation Diameters of Wires:

•

"A" Side (28-32 AWG) ………………………0.71-1.37 mm (0.028-0.054 in.) Dia.

•

"B" Side (22-26 AWG) ………………………0.91-1.52 mm (0.036-0.060 in.) Dia.

Strip Length of Insulation:

•

Discrete and Latch

Housing Applications ……………………….3.81-4.31 mm (0. 150- 0.170 in.)

•

Rod Housing

Applications ………………………………….3.30-3.81 mm (0. 130-0.150 in.)

Wire Barrel Crimp Height:

(For All Applications)

•

Single Wire 22-26 AWG or

Two Wires 26-28 AWG ……………………..0.81-0.86 mm (0.032-0.034 in.)

•

Single Wire 28-32 AWG or

Two Wires 30-32 AWG ……………………..0.66-0.71 mm (0.026-0.028 in.)

Insulation Barrel Crimp Height:

•

Discrete Application …………………………2.84 mm (0. 112 in.) Max.

•

Latch and Rod Housing

Applications ………………………………….1.75 mm (0.069 in.) Max.

Mini PV™ Receptacles:

•

Loose Piece ………………………………….22-32 AWG

NOTE:

Loose piece terminals have different part numbers than reeled terminals.

PDM: Rev:C Released .

STATUS: Printed: Feb 09, 2009