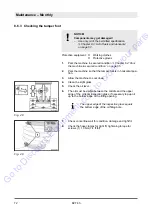

8.6.3 Checking the tamper foot

NOTICE!

Components may get damaged!

–

Use only oil of the permitted specification

Chapter 8.3 ‘List of fuels and lubricants’

.

Protective equipment:

n

Working clothes

n

Protective gloves

1.

Park the machine in secured condition

the machine in secured condition.’ on page 55

2.

Park the machine so that the tamper foot is in horizontal posi-

tion.

3.

Allow the machine to cool down.

4.

Clean the sight glass.

5.

Check the oil level.

6.

The oil must be visible between the middle and the upper

edge of the oil level inspection glass, if necessary top up oil

up to the bottom edge of the filling opening.

The upper edge of the inspection glass equals

the bottom edge of the oil filling bore.

7.

Check concertina wall for condition, damage and tight fit.

8.

Check the hose clamps for tight fit, tightening torque for

screws (1): 10 Nm (7.4 ft

·

lbf).

Fig. 48

Fig. 49

Maintenance – Monthly

BVT 65

72

Go to

Discount-Equipment.com

to

order your parts