29

ENGLISH

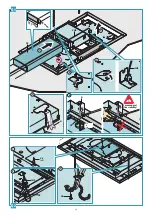

MOTOR UNIT (SLIM) PLACED ON THE HOOD

The motor unit (

SLIM

) is connected directly to the hood.

Phase

The motor unit (SLIM) can also be installed on the hood in various positions in order

to have the desired air outlet direction (Fig.

2

)

Remove the lange (

FC

) assembled on the hood (Fig.

1

) and the knockouts (

ST

) relating

to the deined assembly position of the motor unit (

SLIM

) (Fig.

2

). Assemble the plug

(

TC SLIM

) on the hood, always bear in mind the selected assembly coniguration (Fig.

3

).

Phase

Check the correct position between the elements (

L

) and (

M

), which form the motor unit

(

SLIM

) support brackets in relation to the deined assembly position (Fig.

1

). If required,

position them at the height indicated in (Fig.

2

) and secure them with 8 screws (

V1

).

Secure the support brackets (

L+M

) to the motor unit (

SLIM

) using the 4 screws (

V2

), taking the

desired air outlet direction into consideration (Fig.

3

).

Phase

Place the assembly composed of the motor unit (

SLIM

) and its supports (

L+M

) on the false

ceiling (Fig.

1

), taking care to centre the assembly by means of the laps (

H

) of the protec-

tion template (

G

) (Fig.

2

).

Phase

page 15

Connect the air outlet itting of the motor unit (

SLIM

) to the pipe (

FR

) set up for external

discharge (Fig.

1

).

Set up the electric connection to power the hood only after having disconnected the main

power supply switch and complied with current regulations (Fig.

2

).

Lift the hood towards the false ceiling (Fig.

3

) and pass the chains through the safety holes

of the hood (Fig.

4

).

Lift the knockouts and insert the connector (

CM

) from the motor unit (

SLIM

) into the drilled

hole (Fig.

5

).

Insert the hood in the previously reinforced false ceiling: as the hooks (

G

) open, they provision-

ally support the hood on the false ceiling (Fig.

6

). Tighten all screws (

V3

) in order to open

the hooks (

G

) and block the hood on the false ceiling (Fig.

7

).

Phase

page 16

Fasten the motor unit (

SLIM

) to the hood body using the 4 screws (

V5

) and 4 washers (

V6

)

supplied (Fig.

2

).

Connect the connector (

CM

) of the motor unit (

SLIM

) to the hood connector (

CE

) (Fig.

3

).

Fix the safety chains to the hood using the supplied screws (

V4

) and cut the excess chain

(Fig.

4

). Place back the anti-grease metal ilters removed earlier and then carefully place

back the external suction panel by conducting the steps in phase

C1

on page 10 in reverse

order.

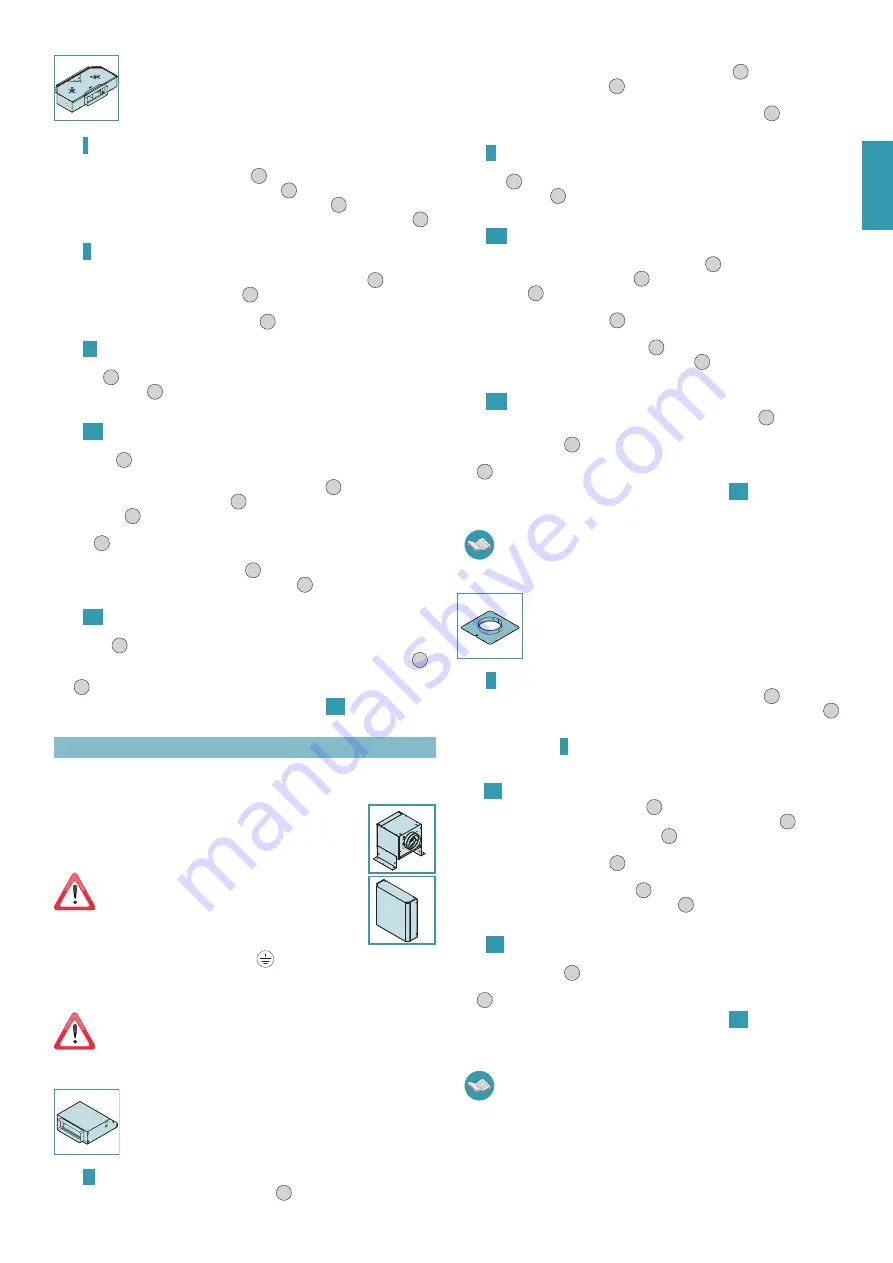

REMOTE MOTOR UNIT (URS OR URE)

The hood can be connected to the under-roof (

URS

) and outdoor (

URE

) remote motor unit .

In the case of an under-roof motor unit (

URS

), it must be placed next to the technical com-

partment inside the home, protected against atmospheric agents and

within reach for any maintenance operations.

In the case of an outdoor motor unit (

URE

), it is recommended to ind a

position protected from rain, snow, wind, etc., in order to prevent rain and

humidity from entering, which can damage the outdoor unit.

In the case of installation with remote motor, you must

connect the hood to the electrical system earthing (after

having veriied its functioning)

by means of a suitable ca-

ble.

To execute this operation, use the threaded insert set up in the hood

structure and identiied with a label and symbol

.

It is recommended that you comply with the current regulations on electrical safety of sys-

tems and devices regarding earthing equipment.

Connection of the suction pipe between the hood and the under-roof (URS)

or outdoor (URE) remote motor unit can be carried out by means of the

lange

(FC)

or air conveyor kit for rectangular pipes (CT) optional

.

Follow the instructions according to the desired installation.

Connection between the hood and the remote unit by means of the

air conveyor kit for rectangular pipes (CT) (OPTIONAL)

The conveyor kit for rectangular pipes (

CT

) enables connection of the

hood to an under-roof (

URS

) or outdoor (

URE

) remote motor unit by

means of suitable rectangular-section pipes.

The conveyor kit for rectangular pipes (CT) is optional.

Phase

Remove the lange (

FC

) assembled on the hood (Fig.

1

).

Check the correct position between the elements (

L

) and (

M

), which form part of the sup-

port brackets of the conveyor kit (

CT

) for rectangular pipes (Fig.

2

). If required, position

them at the height indicated in (Fig.

3

) and secure them with 8 screws (

V1

).

Secure the support brackets (

L+M

) to the conveyor kit for rectangular pipes (

CT

) using the 4

screws (

V2

), taking the desired air outlet direction into consideration (Fig.

4

).

Phase

Place the assembly composed of the conveyor kit (

CT

) and its supports (

L+M

) on the false

ceiling (Fig.

1

), taking care to centre the assembly by means of the laps (

H

) of the protec-

tion template (

G

) (Fig.

2

).

Phase

Connect the kit conveyor air outlet itting for rectangular pipes (

TC

) to the under-roof (

URS

)

or outdoor (

URE

) remote unit with a suitable (

FR

) pipe (Fig.

1

).

Lift the hood towards the false ceiling (Fig.

2

) and pass the chains through the safety holes

of the hood (Fig.

3

).

Lift the knockouts and insert the connector (

CUE

) from the under-roof (

URS

) or outdoor (

URE

)

remote unit into the drilled hole (Fig.

4

).

Insert the hood in the previously reinforced false ceiling: as the hooks (

G

) open, they provision-

ally support the hood on the false ceiling (Fig.

5

). Tighten all screws (

V3

) in order to open

the hooks (

G

) and lock the hood on the false ceiling (Fig.

6

).

Phase

Fasten the kit conveyor (

CT

) to the hood by means of 8 screws (

V5

) (Fig.

1

).

Connect the (

CUE

) connector of the under-roof (

URS

) or outdoor (

URE

) remote unit to the

hood connector (

CE

) (Fig.

2

).

Fix the safety chains to the hood using the supplied screws (

V4

) and cut the excess chain

(Fig.

3

). Place back the anti-grease metal ilters removed earlier and then carefully place

back the external suction panel by conducting the steps in phase

C1

on page 10 in reverse

order.

To assemble the under-roof (

URS

) or outdoor (

URE

) remote motor unit, refer to the

relative instructions booklet.

Hood and remote unit connection by means of the lange (FC)

The lange (

FC

), by means of suitable piping, connects the hood to the

under-roof (

URS

) or outdoor (

URE

) remote motor unit.

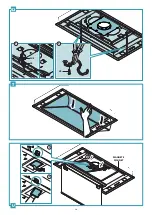

Phase

Should you wish to use a check valve, assemble it on the lange (

FC

) (Fig.

1

); lock it to the

lange by pushing the laps of the itting downwards with a screwdriver or grippers (Fig.

2

). If the under-roof (

URS

) remote motor unit is used, remove the check valve assembled on it

(refer to the instructions

on page

11

).

Phase

Lift the hood towards the false ceiling (Fig.

1

) and connect the lange (

FC

) to the un-

der-roof (

URS

) or outdoor (

URE

) remote unit with a suitable (

F

) pipe (Fig.

2

). Pass the

chains through the safety holes of the hood (Fig.

3

).

Lift the knockouts and insert the connector (

CUE

) from the under-roof (

URS

) or outdoor (

URE

)

remote unit into the drilled hole (Fig.

4

).

Insert the hood in the previously reinforced false ceiling: as the hooks (

G

) open, they provisional-

ly support the hood on the false ceiling (Fig.

5

). Tighten all screws (

V3

) in order to open the

hooks (

G

) and lock the hood on the false ceiling (Fig.

6

).

Phase

Connect the (

CUE

) connector of the under-roof (

URS

) or outdoor (

URE

) remote unit to the

hood connector (

CE

) (Fig.

1

).

Fix the safety chains to the hood using the supplied screws (

V4

) and cut the excess chain

(Fig.

2

). Place back the anti-grease metal ilters removed earlier and then carefully place

back the external suction panel by conducting the steps in phase

C1

on page 10 in reverse

order.

To assemble the under-roof (

URS

) or outdoor (

URE

) remote motor unit, refer to the

relative instructions booklet.

URS

URE

Содержание stella

Страница 7: ...7 800 m3 h 950 m3 h 9 mm...

Страница 9: ...9 X Y X 1 2 Y 4 3 9 mm C...

Страница 12: ...12 120 mm 120 mm M M L UM UM L 2 3 1 1 V1 x8 V2 x4 3 V2 x4 2 V1 x8 A I R A I R E F 1 L M 2 H G UM G...

Страница 13: ...13 UM F 15 950 m3 h 150mm 1 2 3 G V3 6 Smontaggio OK Disassembly G 5 4 x2 H1 2 CM CE 1 V5 x8 V4 3 H2...

Страница 15: ...15 1 2 L M H G SLIM FR 217mm 87mm 800 m3 h 1 2 3 5 4 x2 G V3 7 Smontaggio OK Disassembly G 6 CM M N1...

Страница 16: ...16 3 V4 1 V5 x4 V6 x4 CM CE 2 N2...

Страница 18: ...18 1 V5 x8 CUE CE 2 V4 3 G 5 FR 1 217mm 87mm CUE 2 3 x2 4 G V3 6 Smontaggio OK Disassembly CUE Q2 Q1...

Страница 20: ...20 CUE CE 1 V4 2 S2 T MAGNETE MAGNET 3 1 2 U...

Страница 47: ...47 8 47 110 43 3 150 59 65 25 5 EN60335 2 31 11 07 2002 TC61 7 12 1 15 10 11...

Страница 50: ...50 15 30 51 Stella 4 5 433 92 1 2 1 4 5 5 2 2 10 5 2 ON OFF 1 1 2 3 4 4 7 3 1 1 2 3 4 1 15...

Страница 51: ...51 15 1 2 3 4 4 7 3 1 2 3 15 Magic Steel 1 55 C T 20 U 20 RAEE RAEE...

Страница 87: ...NOTE NOTES...