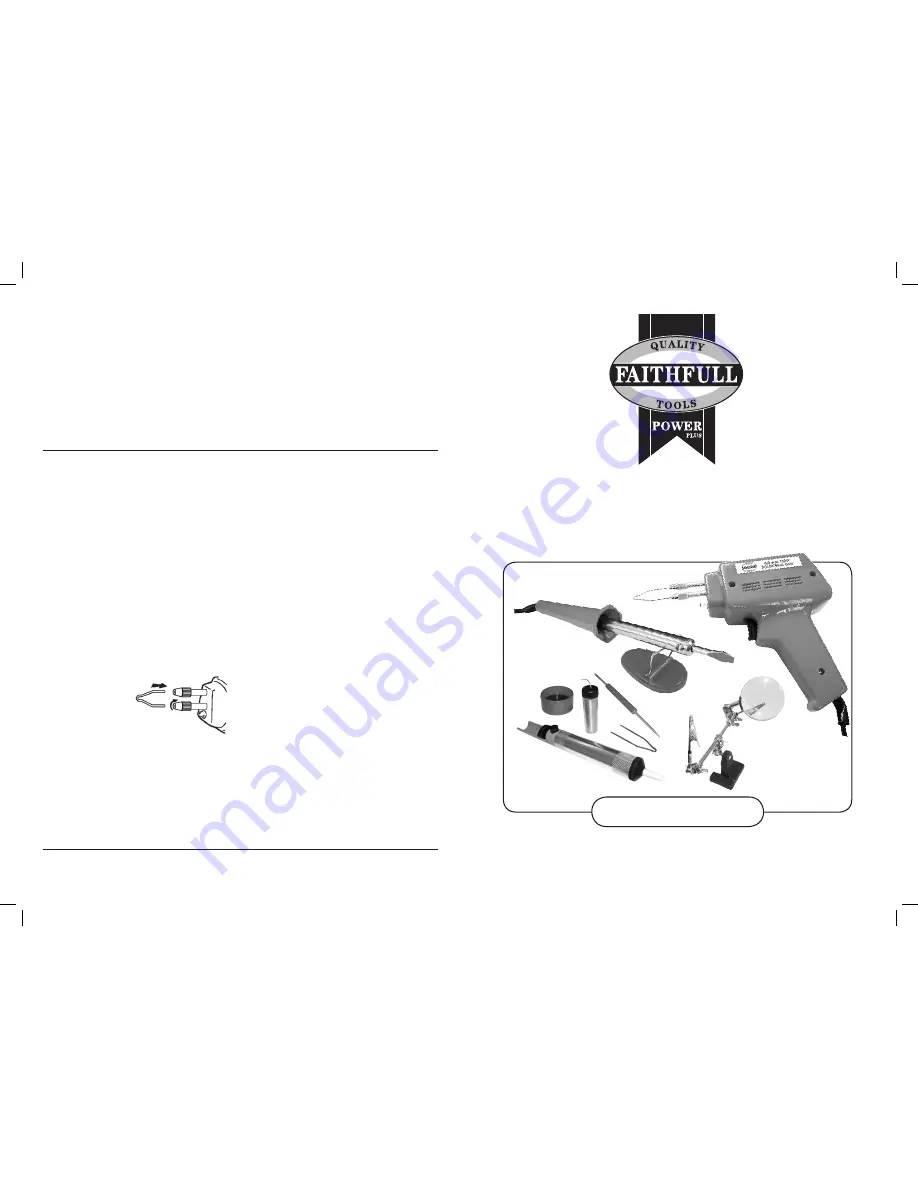

100 Watt Gun, 30 Watt Iron

Soldering Gun and Iron Kit

Instruction Manual

For your own safety, please read these instructions carefully

1. Check that the voltage displayed on the nameplate is

the same as the mains power source.

2. Before switching on, make sure the soldering tip is

properly in position and that the tip clamp screws are

tight.

3. Connect to an appropriate 230 volt mains outlet

socket, and switch the socket on (if applicable).

4. Press the trigger and the operating light will illuminate

indicating that the gun is heating. The temperature

will rise to 300 degrees in 20 seconds, the gun is now

at is operating temperature.

5. Never try to lock the trigger in the ‘On’ position by any

means. This will cause overheating and burn out the

tip, resulting in permanent damage to the gun and to

the transformer.

6. Soldering tips must only be removed when the

soldering gun is cool and disconnected from the

mains supply. Loosen the two clamping screws and

slide the soldering tip out carefully,

without using excess force.

Insert the new tip fully

into the gun and tighten

the two retaining screws.

7. Do not heat up the soldering gun

without the soldering tip fitted in place.

8. After use, allow the soldering gun to cool down

naturally in the air (do not attempt to speed up the

cooling process by applying water or any other liquid).

9. The power lead fitted to the soldering gun is a

special high quality cable, and it is resistant against

short-time contacts with hot metal parts. In the event

of damage to the power lead, it cannot be exchanged

due to the special construction of the soldering gun.

The gun can then no longer be used according to the

safety prescriptions.

Operating Instructions For The Soldering Gun

Before using the soldering gun please carry out

the following checks:

Operating Instructions For The Soldering Iron

Before using the soldering iron, it is recommended

that the following checks are carried out:

1. Check that the voltage displayed on the nameplate is

the same as the mains power source.

2. Before switching on, make sure the soldering tip is

properly in position and that the tip clamp screw is

tight.

3. Connect to an appropriate 230 volt mains outlet

socket, and switch the socket on (if applicable).

4. Soldering tips must only be removed when the

soldering iron is cool and disconnected from the

mains supply. Loosen the clamping screw and

remove the soldering tip carefully, without using

excess force. Insert the new tip fully into the iron and

tighten the retaining screw.

5. Do not heat up the soldering iron without the

soldering tip fitted in place.

6. After use, allow the soldering iron to cool down

naturally in the air (do not attempt to speed up the

cooling process by applying water or any other liquid).

7. When in use, always place the soldering iron on is

metal holder for safe storage.

8. The power lead fitted to the soldering iron is a special

high quality cable, and it is resistant against short-

time contacts with hot metal parts. In the event of

damage to the power lead, it cannot be exchanged

due to the special construction of the soldering iron.

The iron can then no longer be used according to the

safety prescriptions.

Replacement tips are available from your local Faithfull Tools stockist or online from www.toolbank.com

Please ensure that these instructions are read by the operator before using the product, and that all the safety guidelines

are understood. Please keep these instructions for future reference.

Soldering is a process for joining two metals by the

application of molten material. Nearly all metals and

metal alloys, brass, copper, iron etc, can be soldered.

There are two types of soldering: hard soldering and soft

soldering.

Hard soldering

is a process carried out at temperatures

over 450ºC. The hard soldering alloys (for hard soldering,

brazing and solver soldering) are made of metal alloys

that are first melted at temperatures that cannot be

achieved by a soldering iron.

Soft soldering

is a process carried out at temperatures

below 400ºC, and this appliance is designed for soft.

The surfaces to be soldered should be kept clean and

free from oil and dirt. Never use household detergents

since they often contain silicon. The oxide coating can

be removed by using either the chemical corrosion

method, emery paper, or by filing or scraping. If the

corrosion method is used, avoid using hydrochloric,

sulphuric or nitric acid. Citric acid, at a 10% dilution ratio,

is recommended. When cleaning is finished, do not

touch surfaces to be soldered. The correct temperature

is attained when tin deposited on the tips forms a smooth

coat. The formation of small clots means the correct

temperature has not been attained. If tin ‘pearls’ are

formed, the tip is not properly clean.

SOldeRInG

CautIon

1. Always use an appropriate soldering stand, and any other

soldering aids which are designed to avoid burns.

2. Always check that the soldering tip is fitted firmly in place

before switching on. The soldering tip must be pushed

fully into the heating unit, and tightly fastened with its

clamping screw.

3. After use, allow the soldering iron to cool down naturally

in the air (do not attempt to speed up the cooling process

by applying water or any other liquid).