Functional characteristics

Machine configuration menu

099-0M37XM-EW501

16.07.2018

29

1 Preparation

• Switch off the welding machine.

• Unscrew the gas nozzle from the welding torch.

• Trim the welding wire so that it is flush with the contact tip.

• Retract the welding wire a little (approx. 50 mm) on the wire feeder. There should be no more welding

wire in the contact tip at this point.

2 Configuration

• Press and hold the “Welding power rotary knob”; at the same time switch on the welding machine (at

least 2 s). Release the rotary knob (after a further 5 s the device will switch to the cable resistance 1

parameter).

• Turn the “Welding power rotary knob” to select the appropriate parameter. The “rL1” parameter has to

be adjusted for all machine combinations.

3 Alignment/Measurement

• Applying slight pressure, put the welding torch in place with the contact tip on a clean, purged location

on the workpiece and then press the torch trigger for approx. 2 seconds. A short-circuit current will

flow briefly, which is used to determine and display the cable resistance. The value can be between

0

mΩ and 40 mΩ. The new value is immediately saved without requiring further confirmation. If no

value is shown on the right-hand display, then measurement failed. The measurement must be

repeated.

4 Restoring welding standby mode

• Switch off the welding machine.

• Screw the gas nozzle onto the welding torch.

• Switch on the welding machine.

• Insert the welding wire again.

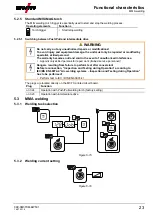

5.5.3

Power-saving mode (Standby)

You can activate the power-saving mode by setting a parameter in the machine configuration menu (time-

controlled power-saving mode

)

> see 5.5 chapter

.

When power-saving mode is activated, the machine displays show the horizontal digit in the

centre of the display only.

Pressing any operating element (e.g. turning a rotary knob) deactivates power-saving mode and the

machine is ready for welding again.