Functional characteristics

Special parameters (advanced settings)

24

099-0M37XM-EW501

16.07.2018

5.3.3

Arcforce

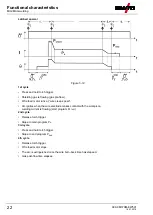

Figure 5-17

Setting:

• Negative values: rutile electrode types

• Values at zero: basic electrode types

• Positive values: cellulose electrode types

5.3.4

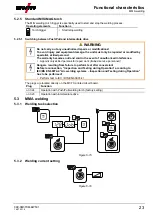

Hotstart

The function hot start ensures a secure igniting of the arc and a sufficient heating to the still cold parent

metal at the beginning of the welding process. The ignition takes place here with increased current (hot

start current) over a certain time (hot start time).

A = Hot start current

B = Hot start time

C = Main current

I =

Current

t =

Time

Figure 5-18

5.3.5

Antistick

The Antistick feature prevents the electrode from annealing.

Should the electrode stick despite the Arcforce feature, the machine

automatically switches to the minimum current within approx. one

second. This prevents the electrode from annealing. Check the welding

current setting and correct for the welding task in hand.

Figure 5-19

5.4

Special parameters (advanced settings)

Special parameters (P1 to Pn) are applied for customer-specific configuration of machine functions. This

allows the user maximum flexibility in optimising their requirements.

These settings are not configured directly on the machine control since a regular setting of the

parameters is generally not required. The number of selectable special parameters can deviate between

the machine controls used in the welding system (also see the relevant standard operating instructions).

If required, the special parameters can be reset to the factory settings

> see 5.4.2 chapter

.