Functional characteristics

TIG welding

099-00L200-EW501

13.05.2022

35

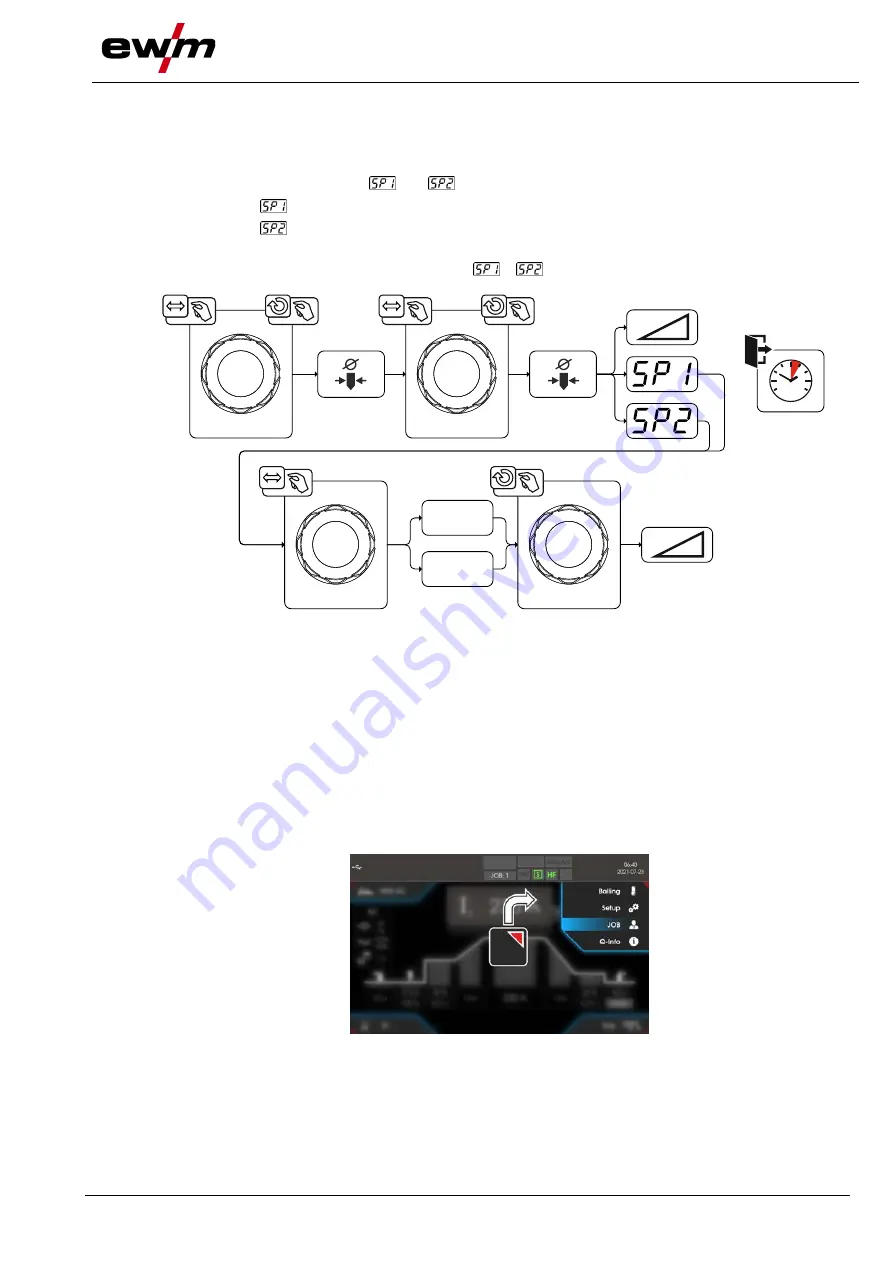

5.1.2.2 Manual ignition setting

When the special ignition is selected, the dependency of the minimum current limits on the electrode di-

ameter is disabled. The ignition energy can now be set independently with the parameters ignition current

I

ign

and ignition time t

ign

. The ignition time is set absolutely in milliseconds. The setting of the ignition cur-

rent differs in the setting variants

and

.

• In the variant

, the ignition current is set absolutely in ampere [A].

• In the variant

, the ignition current is set as a percentage of the set main current.

The parameters for manual setting of the ignition energy are selected and enabled with “left stop” when

setting the electrode diameter (minimum value >

>

).

4s

I

ign

t

ign

Figure 5-4

5.1.2.3 Recurring welding tasks (JOB 1-100)

The user has 100 additional memory locations at their disposal to save recurring or different welding

tasks on a permanent basis. To do so, simply select the required memory location (JOB 1-100) and set

the welding task as described previously.

With the JOB manager

> see 5.5 chapter

, welding tasks can be copied to any preset or reset to the fac-

tory settings.

The desired JOB can also be assigned to a quick access button (favourites button)

> see 5.4 chapter

.

Switching a JOB is only possible if no welding current flows. Up-slope and down-slope times can be set

individually for latched and non-latched operation.

Selection

Figure 5-5