Design and function

Transport and installation

099-005592-EW501

16.07.2018

15

5.1.3

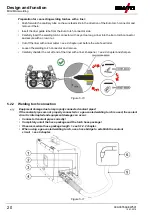

Notes on the installation of welding current leads

• Incorrectly installed welding current leads can cause faults in the arc (flickering).

• Lay the workpiece lead and hose package of power sources without HF igniter (MIG/MAG) for

as long and as close as possible in parallel.

• Lay the workpiece lead and hose package of power sources with HF igniter (TIG) for as long as

possible in parallel with a distance of 20 cm to avoid HF sparkover.

• Always keep a distance of at least 20 cm to leads of other power sources to avoid interferences

• Always keep leads as short as possible! For optimum welding results max. 30 m (welding lead

+ intermediate hose p torch lead).

Figure 5-1

Use an individual welding lead to the workpiece for each welding machine!

Figure 5-2

Fully unroll welding current leads, torch hose packages and intermediate hose packages. Avoid

loops!

Always keep leads as short as possible!

Lay any excess cable lengths in meanders.

Figure 5-3