- 12 -

3. Technical specifications

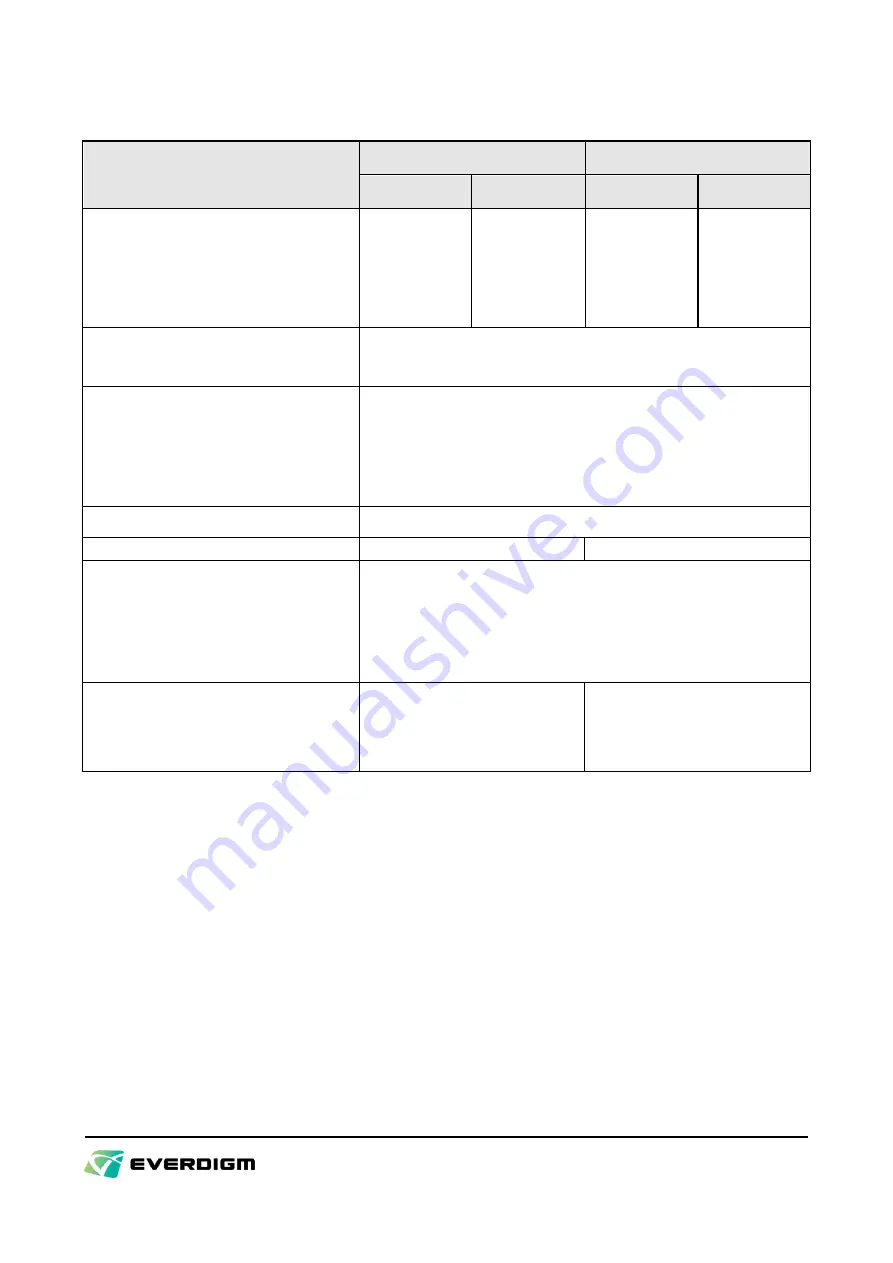

Model

EPG05

EPG08

Rib Type

Perforated Type

Rib Type

Perforated Type

Weight

1)

kg

432

419

568

548

Height of opened grab(B)

mm

1,162

1,162

1,303

1,303

Width of grab shells(W)

mm

600

600

700

700

Width of opened grab(A)

mm

1,533

1,533

1,736

1,736

Oil flow

lpm

20 ~ 60

Max. Operating Pressure

bar

300

Max. Oil Flow for Rotation

lpm

20

Max. Pressure for Rotation

bar

140

Max. Rotation Speed

rpm

15

Rotating Angle

> 360

° (Continuous)

Operating Oil Temperature

°

C

-20 ~ +90

Recommended Carrier Weight

2)

tonne

4 ~ 8

7 ~ 10

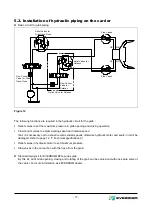

Hose Connections

Main

Pressurizing Port

„MA‟ : Grab Closing

Pressurizing Port

„MB‟ : Grab Opening

Rotation

(at the view from carrier)

Pressurizing Port

„RA‟ : Counter-clockwise

Pressurizing Port

„RB‟ : Clockwise

Type of Hose Connection Ports

)

Main (Port

„MA‟ and „MB‟)

BSP 3/8

BSP 1/2

Rotation (Port

„RA‟ and „RB‟)

BSP 3/8

BSP 1/2

Notes : 1) Total weight excluding mounting adaptor, hydraulic hoses, fittings and mounting pins.

2) The carrier weight must be heavier in case long boom and/or long arm are equipped. For more details, consult

the manufacturer of the carrier.

3) JIS B2351 type

„O‟ O-ring boss ports.

Содержание EPG05

Страница 1: ...OPERATION MAINTENANCE MANUAL Multi Purpose Grab Document No MSAGUS 0005 Revision Date 2014 09 23...

Страница 36: ...36 Notes...

Страница 37: ...37 Notes...