11

2500233-01-05/19 (Translation of the original operating instructions)

Operating Instructions Safety Systems

MGB2-L1…-BR.-… / MGB2-L2…-BR.-… and MGB2-L1…-BP.-… / MGB2-L2…-BP.-…

EN

6. Function

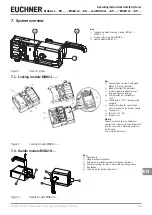

6.1. Locking module MGB2-L1/L2

Together with a handle module, the locking module makes it possible to lock movable guards. The combination also serves

as a mechanical door stop at the same time.

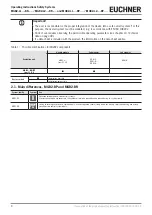

DIP

OFF

ON

The following switch-on condition applies to the safety outputs FO1A and FO1B (also see chapters 15.2. System

status table MGB2-BR on page 43 and 15.3. System status table MGB2-BP on page 45):

DIP switch

Configuration

System family

MGB2-BR

MGB2-BP

Guard locking monitoring

active

inactive

active

inactive

Condition

No fault in the device

&

TRUE

TRUE

TRUE

TRUE

Guard closed

TRUE

TRUE

TRUE

TRUE

Bolt tongue inserted in locking module

TRUE

TRUE

TRUE

TRUE

Guard locking active

TRUE

Not relevant

TRUE

Not relevant

In case of series connection:

Signal available from the upstream switch on the safety inputs FI1A

and FI1B

In case of separate operation:

DC 24 V present at the safety inputs FI1A and FI1B

TRUE

TRUE

Not relevant

Not relevant

FO1A and FO1B are

ON

The locking module detects the position of the guard and the position of the bolt tongue. The position of the guard locking

is also monitored.

Guard locking monitoring can be deactivated using DIP switches (see chapter 13.7. Changing device configuration (using

Important!

For use as guard locking for personnel protection in accordance with EN ISO 14119, guard locking

monitoring must be active.

The bolt tongue in the handle module is moved into and out of the locking module by actuating the door handle.

When the bolt tongue is fully inserted into the locking module, the locking arm locks the bolt tongue in this position. Depending

on the version, this locking is by spring force or solenoid force.