24

MAINTENANCE

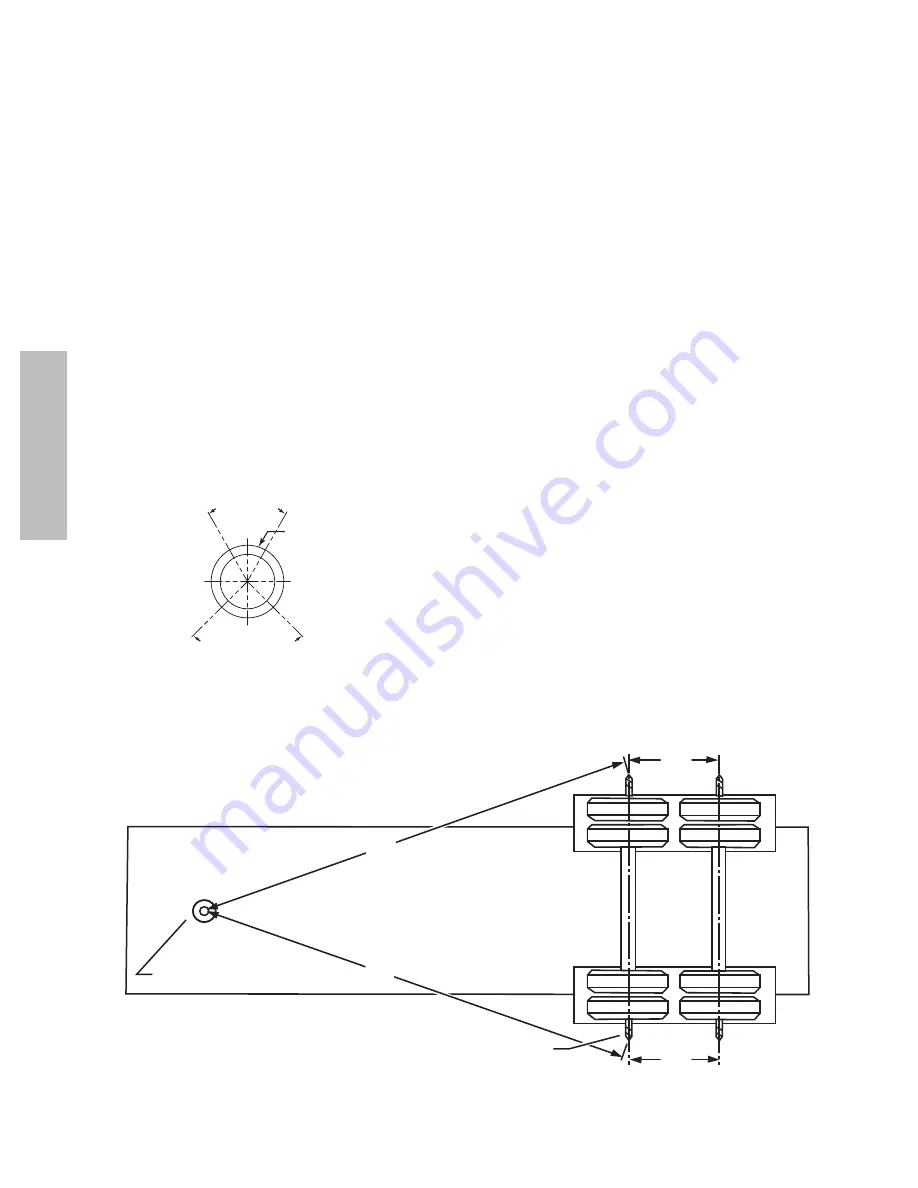

3" NO WELD

ZONE

4" NO WELD

ZONE

TOP OF

AXLE

D) Multiple pass welding may be used on the beam/

axle connection using the following guidelines. Total

fillet weld size should be 1/2" (12.7mm).

Multiple pass (recommended method, SMAW,

GMAW, FCAW) weld initiation and termination should

be performed as outlined and shown in (Figure 17).

NOTE: All slag must be removed between passes.

Backstep fill all craters. Each pass must be accom-

plished in two segments. Recommended electrode is

E7018 if SMAW (stick) is used.

IMPORTANT: It may be necessary to C-clamp

axle to axle beam seat prior to welding. This will

insure that complete contact occurs between the axle

housing and beam seat.

Repair Welding

If the beam/axle weld is cracked or broken, the weld

Figure 18. No Weld Zones

can only be repaired if the crack or break does not

extend into the axle tube. To repair the weld, grid or

back gouge the weld/crack down to the base metal. If

the crack extends into the axle tube, or if any other area

of the axle is cracked, the axle must be replaced. Apply

the repair weld according to the information in Sec-

tions 1-3 of the guideline.

Welding Precautions

A) All welds must be kept away from the top and

bottom of the axle where maximum stresses occur. The

"no weld" zones are illustrated in (Figure 18).

B) Do not test weld the arc on any part of the

axle tube. This can cause a material change which can

lead to a small crack that may eventually grow and af-

fect the fatigue lift of the axle.

Figure 19. Alignment of Axle

1 6450076 BAZOOKA

2 6450077 AXLE EXTENSION SET

AXLE EXTENSION SET SHOWN IN PLACE

SR

SL

LL

LR

SL = SR =

±

1/16

LL = LR =

±

1/16