EPSON Stylus Pro 10000/10000CF

Revision B

Operating Principles

Printer Mechanism Components

70

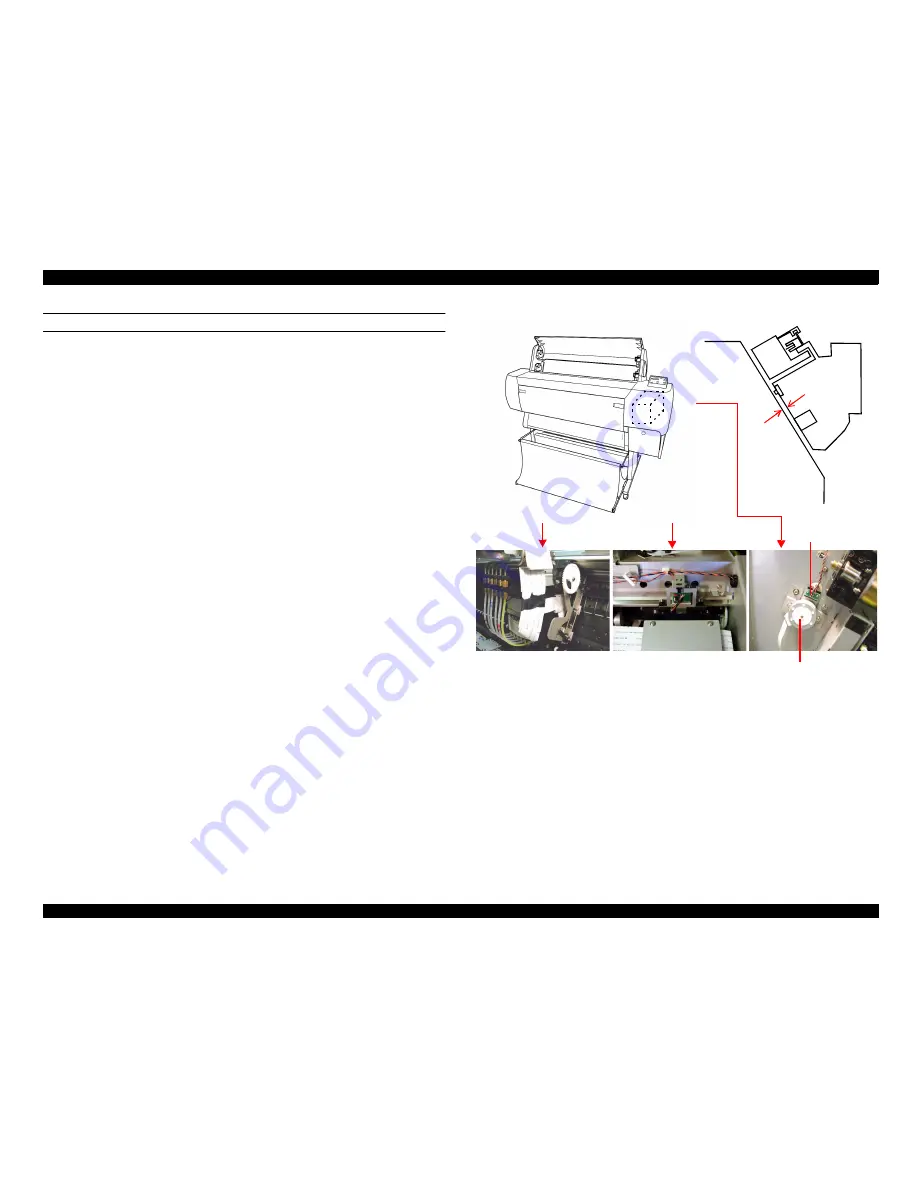

PLATEN GAP ADJUSTMENT SECTION

the carriage (=head) mounting location always needs to keep regular distance to the space

for printing precision maintenance.

In this printer, as the gap between the form printing face and also head nozzle face become

regular according to paper thickness, the print head nozzle face is variable structure.

The sub carriage that fixed the print head on the carriage that makes the carriage 2 body

structure and become a base is being installed. For the sub carriage moves it in vertical

direction to the space. The cam is used to this mobile system. From the home location of

cam (=PG), for sub carriage to space period changes into linear. When the carriage is in HP

location (the right edge) the gear that was attached on the PG motor and sub carriage drives

the cam, motor revolution (reverse) and cause the sub carriage positioned to specified gap

location.

Doing the paper thickness that is used to 3 stages of the PG small (1.3 mm)/the middle (2.2

mm)/large (2.7 mm) the class division, to keep the distance between the print head nozzle

face and form regularly.

Ink viscosity receives the influence to temperature. The thermistor for temperature

detection is built to each print head, to control ink protrusion speed/protrusion quantity to

same even if temperature changes.

Figure 2-4. Carriage device department-PG adjustment department

The explanation of the sensor that is used in platen gap adjustment department is as follows.

o

HD_SLID (head gap starting point detection) sensor

The mechanical origin (the home) the location detection at the time of modification

actuation for the sub carriage location (the head height from the space) on the carriage.

Being using the reflection style photograph sensor that was attached to I/S frame the

hole location of the gear that was attached on the sub carriage is being detected. When

sensor output is becoming the constitution that becomes "off" (Less than 2.0V) with

the location that the sub carriage dropped most and be actuated detection, sensor output

that the head lowers from the location that rose upward makes the point that changed to

"on" (Over 3.0V) from "off" the mechanical origin and recognize.

CR

guide

rail

HD_SLID sensor

Slide motor

Содержание Stylus Pro 10000 Series

Страница 7: ...Revision Status ...

Страница 8: ...Revision Issued Date Description Rev A March 30 2001 First Release ...

Страница 13: ...C H A P T E R PRODUCTDESCRIPTION ...

Страница 59: ...EPSON Stylus Pro 10000 10000CF Revision B Product Description Jumper Settings 59 ...

Страница 60: ...C H A P T E R OPERATINGPRINCIPLES ...

Страница 86: ...C H A P T E R TROUBLESHOOTING ...

Страница 113: ...C H A P T E R DISASSEMBLY ASSEMBLY ...

Страница 187: ...C H A P T E R ADJUSTMENT ...

Страница 256: ...EPSON Stylus Pro 10000 10000CF Revision B Adjustment Self Diagnostics 256 Following table showing the items ...

Страница 276: ...C H A P T E R MAINTENANCE ...

Страница 289: ...C H A P T E R APPENDIX ...

Страница 302: ...INK SYSTEM ASSY 451 PM10 MC10 EPSON STYLUS PRO 10000 10000CF No 6 Rev 01 10282 456 455 454 453 452 457 ...

Страница 307: ...PM10 MC10 EPSON STYLUS PRO 10000 10000CF No 11 Rev 01 10282 SPINDLE ASSY 902 901 195 902 901 196 ...

Страница 309: ...EPSON Stylus Pro 10000 10000CF Revision A Appendix Component Layout 309 Figure 7 3 C362SUB Board Component Layout ...

Страница 311: ...EPSON Stylus Pro 10000 10000CF Revision A Appendix Component Layout 311 Figure 7 6 C362DRV Board Component Layout 1 2 ...

Страница 312: ...EPSON Stylus Pro 10000 10000CF Revision A Appendix Component Layout 312 Figure 7 7 C362DRV Board Component Layout 2 2 ...

Страница 315: ......

Страница 316: ......

Страница 317: ......

Страница 318: ......

Страница 319: ......

Страница 320: ......

Страница 321: ......

Страница 322: ......

Страница 323: ......