Owner's Manual for EPILOG Legend Model 6000

December, 2000

50

Section 10 – Engraving Techniques

ACRYLIC VECTOR CUTTING TECHNIQUES

Acrylic is one of the most popular cutting materials available. It comes in a variety of colors and thickness.

Laser cutting produces very nice edge quality without the need for polishing or secondary clean up.

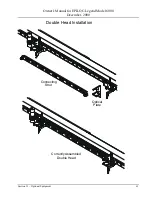

Use a Vector Table to elevate the acrylic before cutting. Air Assist will greatly reduce flaming when cutting

acrylic.

Vectoring acrylic is similar to vectoring other materials. First, experiment to determine the correct speed and

power setting. Cutting acrylic is usually best achieved with relatively slow speed and relatively high power.

This combination allows the laser beam to melt the edges of the acrylic and produce an almost flame polished

edge. Acrylics generally require only a single pass to cut, but thicker acrylics may need two passes.

As with engraving, it is sometimes necessary to mask and dampen the acrylic before cutting.

Warning!

Never leave your Legend unattended when vector cutting acrylic! Acrylic is very

flammable.

ANODIZED ALUMINUM

Anodized aluminum comes in a variety of colors and can usually be easily engraved with a CO2 laser. Black

anodized aluminum is great to work with because it turns white when lasered. Black anodize provides the

best contrast of all of the colors of anodized aluminum. Some colors of anodize – red for instance – will not

turn completely white when laser engraved. Red anodize will produce a light pink color. Performing a

second pass can see some improvement but usually a slight shadow of color will remain.

Engrave anodized aluminum at high speeds and low powers for crisp, clean images. Too much power applied

to the anodize will distort the engraving and tends to over-burn the image.

Warning!

Metals are reflective, and using full power will potentially cause damage to the machine.

BRASS - PAINTED

BRASS BACKGROUND

Un-coated brass cannot be laser engraved. In order to engrave brass with a laser you need to use brass that

has some sort of coating – typically paint. The laser removes the paint and exposes the brass substrate. There

are three basic types of engraving brass available to engravers but they are not all compatible with the laser.

By far, the most popular laser brass is actually brass-coated steel. First, a steel substrate is coated with a thin

layer of brass. Next, the brass is polished to a reflective finish and a coat of lacquer is applied to the brass.