High Temperature Refrigerated Air Dryers

Installation Instructions

notice!

Improper installation methods of air

inlet and air outlet piping that causes

internal damage to the air dryer

system will void warranty. Installer

should follow proper pipe installation

practices or hire a certified contractor

to install this unit.

notice!

Before installing the air dryer system,

make sure that the unit has at least 24

inches of clearance around all sides and

at least 24 inches of clearance on top.

This is required to provide proper air

circulation to the unit. Also, a floor drain

must be provided for moisture and oil

drainage. The unit must stand above

the floor drain by at least an inch or two

for proper drainage. If the floor drain

is located further from the unit than 3

Ft., obtain longer hoses locally (refer

to the installation instruction Step 5 for

proper dimensions). If it is impossible

to connect the unit to a floor drain, a

container can be made to collect the

drainage. This container must have a

lid to prevent the pressurized drainage

from spraying. This lid must have an air

hole to allow the air inside to escape

when the drainage is discharged.

Remove unit from carton and VISUALLY

inspect for damage.

To install the optional coalescing oil

filter, thread a pipe nipple on the air

outlet connection. Install the filter to the

pipe nipple with arrow on filter pointing

away from air dryer unit. Use pipe

sealer on both ends of the nipple to

facilitate sealing without undue torque

pressure.

♦

♦

notice!

Optional coalescing oil filter must be

installed with direction arrow facing

AWAY from the air dryer system unit.

If the oil filter is installed backwards,

discharge air will be contaminated

with oil.

Connect discharge air line to the dryer

or optional filter outlet connection.

Connect air piping from the air

compressor to the air dryer system

inlet connection. Use caution when

connecting piping to the air dryer

system to avoid twisting and damaging

the air connection.

notice!

Install brackets and support fixtures

as needed to eliminate fatigue and

vibration in the air system piping.

Drain Connection -

Models QPHT 25

and QPHT 50 are equipped with a 1/2”

OD plastic moisture drain tube. The

drain tube needs to be directed to a

proper drain point. A longer drain tube

or extension may be required. Be sure

to provide a secure attachment as the

moisture drain tube will periodically be

under pressure.

Drain Connection -

Models QPHT 75,

100 and 125 are equipped with a 3/8”

NPTF drain connection. A plastic drain

tube or copper pipe must be attached

and directed to a proper drain point.

Be sure to provide a secure attachment

as the moisture tube or pipe will

periodically be under pressure.

♦

♦

♦

♦

4

Quincy Compressor-QPHT

Back to TOC

Содержание Quincy Compressor QPHT 100

Страница 2: ......

Страница 4: ......

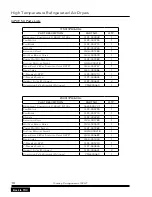

Страница 24: ...High Temperature Refrigerated Air Dryers QPHT 25 Dimensional 20 Quincy Compressor QPHT Back to TOC ...

Страница 25: ...High Temperature Refrigerated Air Dryers QPHT 50 Dimensional Quincy Compressor QPHT 21 Back to TOC ...

Страница 26: ...High Temperature Refrigerated Air Dryers QPHT 75 100 125 Dimensional 22 Quincy Compressor QPHT Back to TOC ...

Страница 27: ...High Temperature Refrigerated Air Dryers QPHT 25 Wiring Diagram Quincy Compressor QPHT 23 Back to TOC ...

Страница 28: ...High Temperature Refrigerated Air Dryers QPHT 50 Wiring Diagram 24 Quincy Compressor QPHT Back to TOC ...

Страница 29: ...High Temperature Refrigerated Air Dryers QPHT 75 115V Wiring Diagram Quincy Compressor QPHT 25 Back to TOC ...

Страница 30: ...High Temperature Refrigerated Air Dryers QPHT 75 230V Wiring Diagram 26 Quincy Compressor QPHT Back to TOC ...

Страница 37: ......