EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

6

3.0 Installation

Each device has a M4 x 1.5 thread tapped into the base of the enclosure and can be used for

mounting. In high vibration applications rubber mounting is recommended.

CAUTION:

When mounting the device inside the engine compartment, it should be

positioned in cooler areas and away from heat sources such as exhaust manifolds. Any

unnecessary radiated heat may affect device performance.

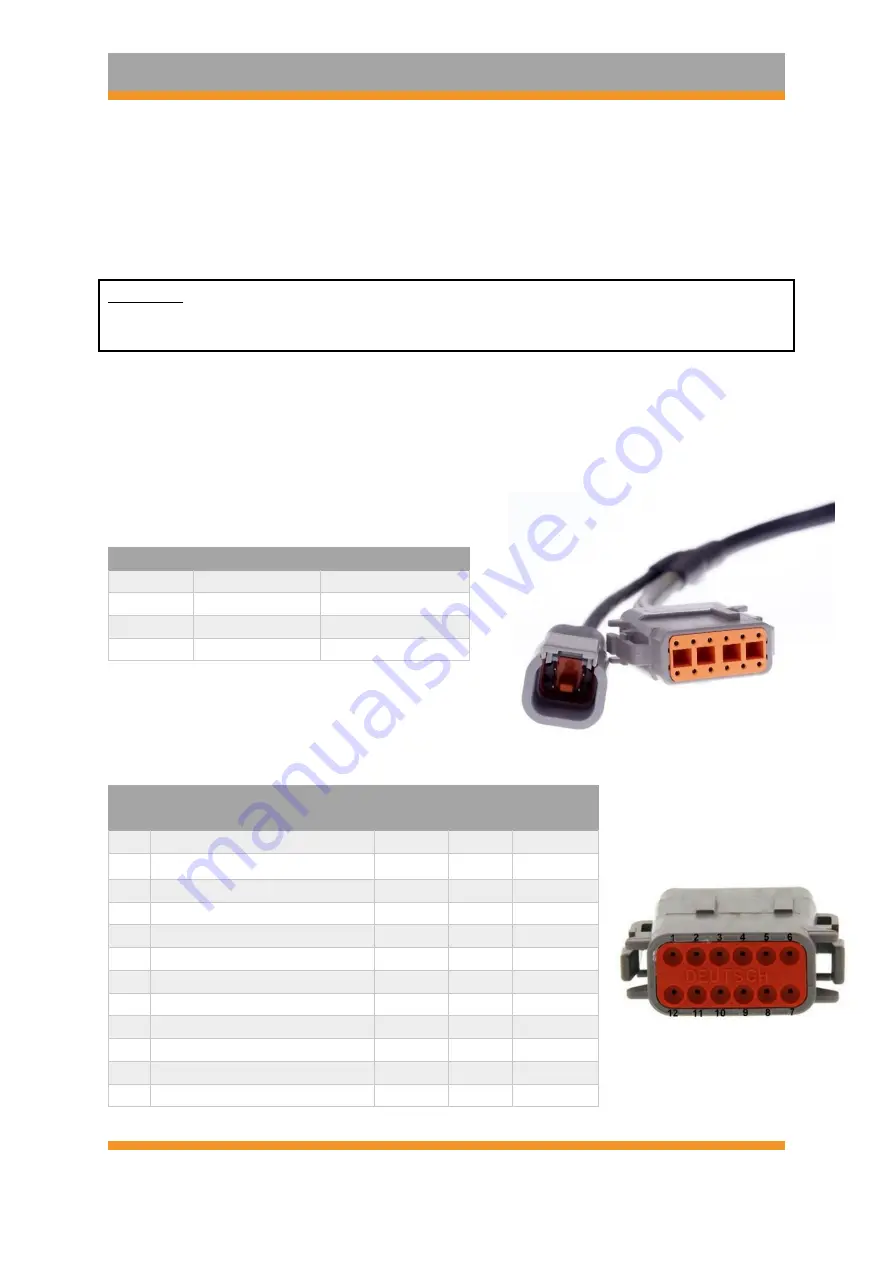

3.1 EIC10 Pinout

The pinouts are shown below in Table 3.0 and Table 3.1.

Power and CAN Flying Loom Connector: DTM 4 pin

(M).

Pin

Function

Wire Colour

1

Ground

BLACK

2

CAN Lo

GREEN

3

CAN Hi

YELLOW

4

12V Supply

RED

Table3.0. EIC10 Power and CAN Deustch Connector

Pinout

Analog Input Flying Loom Connector: DTM 12 pin (F).

Pin Function

Voltage

Range

Pullup Wire

Colour

1

Analog Voltage 1

0 - 5.0V No

BRN

2

Analog Voltage 2

0 - 5.0V No

BLUE

3

Analog Voltage 3

0 - 5.0V No

GREY

4

Analog Voltage 4

0 - 5.0V No

W/GREY

5

Analog Voltage 5

0 - 5.0V No

W/BLUE

6

5V Sensor Supply

W/BRN

7

Analog Sensor 0V Reference

W/RED

8

Analog Voltage 6

0 - 5.0V No

W/BLACK

9

Analog Voltage 7/ Freq 1

0 - 5.0V Yes

W/OR

10

Analog Voltage 8/ Freq 2

0 - 5.0V Yes

OR

11

Analog Voltage 9/ Freq 3

0 - 5.0V Yes

WHITE

12

Analog Voltage 10/Freq 4

0 - 5.0V Yes

PUR

Table3.1. EIC10 Input Deustch Connector Pinout (DTM06-12SA)