22

23

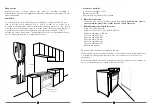

Minimum Clearances

When the upright cooker is installed abutting a side or rear wall, the wall must be

of non-combustible material, eg ceramic tiles. The following minimum clearances

to combustible materials must be observed:

• Minimum clearance from hotplate to side wall must be 200 mm.

• Minimum clearance from hotplate to rear wall must be 200 mm.

INSTALLATION INSTRUCTIONS

These instructions are for the use of a qualified installer only

Statutory regulations

This appliance is to be installed in accordance with the manufacturer’s installation

instructions, local gas fitting regulations, applicable building codes, electrical wiring

regulations, and according to the installation code for Gas Appliances AS5601/AG6O1.

Consult SAA wiring rules as appropriate.

Safety Warnings About Installation

• The cooker must be installed and serviced by a qualified technician.

• A certificate of compliance must be supplied by the installer and kept

by the customer.

• All packaging materials including protective plastic film must be removed

before the cooker is installed.

• The pipes used in installation must have sufficient loops to allow for the

cooker to be moved for service.

• The safety chain must be fitted.

• The cooker must not be lifted or pulled using the oven handle

• The cooker must be serviced and checked every 3 to 4 years depending

on usage or condition.

7.

Grill Element/Top Element - All models:

This element must never be sprayed with

any detergents. A damp cloth and a bottlebrush can be used to clean the roof of the

oven and the element itself. Never soak the element and always dry it after cleaning as

not doing so can lead to deterioration. It is important to clean this area regularly as fats

spit up and stick to the ceiling and element while grilling and they may burn, smoke

and

give out unpleasant odours.

WARNING:

please follow these safety precautions

during cleaning

.

Avoid the ignitors becoming wet, as this is an electrical part and moisture can cause it to

malfunction.

Avoid water spilling into hob burner holes when burners have been removed.

Always dry unit before use, never let water and detergents sit in and on unit.

CARE OF CATALYTIC LINERS

Some models have catalytic liners installed within the oven cavity. They are the matte

finished light coloured panels on the sides and the matte finished panel at the rear of the

oven.

They work by collecting the grease and oil residues that occur during cooking. The

liner self cleans by absorbing fats and oils and burning them to ash which is then easily

removed from the floor of the oven with a damp cloth.

The liner may discolour with age and should a large amount of fat be spilled onto the

liner it may affect its efficiency. To overcome this problem set the oven to maximum

temperature for about 10 - 20 minutes. Catalytic liners are designed for a working life

of about 300 hours.

When the oven is cool wipe out the floor of the oven.

Manual cleaning of the catalytic liners is not recommended. Damage will occur if

soap impregnated steel wool pad or any other abrasives are used. We also do not

recommend the use of aerosol cleaners on the liners.

If the walls of a catalytic liner are no longer effective you can remove the surplus grease

with a soft cloth or sponge soaked in hot water then go through the cleaning cycle as

described above. The lining must be porous to be effective. Catalytic liners are designed

for a working life of about 300 hours.

KITCHEN CABINETRY WARNING

NOTE:

ALL ADJACENT SURFACES TO THE COOKER MUST BE ABLE TO

WITHSTAND NORMAL HEAT TRANSFER FROM THE COOKER AND THE HEAT

RELEASED FROM THE OVEN DOOR WHEN OPENED. GLEMGAS ACCEPTS NO

RESPONSIBILITY FOR CABINET DAMAGE FOR DAMAGE TO KITCHEN

CUPBOARDS AND DRAWERS DUE TO INCORRECT INSTALLATION. IF IN DOUBT

INSTALL A HEAT SHIELD.

VINYL WRAPPED CUPBOARD FINISHES ARE NOT A SUITABLE SURFACE.

CALL GLEM GAS ON 1 300 307 917 FOR ADVICE.