Maintenance

▲

WARNING

To avoid personal injury, property

damage or equipment damage caused

by sudden release of pressure or

explosion of accumulated gas, do

not attempt any maintenance or

disassembly without first isolating the

pilot from system pressure and relieving

all internal pressure from the pilot.

Pilots that have been disassembled

for repair must be tested for proper

operation before being returned to

service. Only parts manufactured by

Emerson should be used for repairing

this pilot.

Due to normal wear or damage that may

occur from external sources, this pilot

should be inspected and maintained

periodically. The frequency of inspection

and replacement of parts depends upon

the severity of service conditions or the

requirement of local, state and federal

rules and regulations.

△

CAUTION

Do not, under any circumstances, loosen

the bolts on the diaphragm chamber of

the Type T124 or T134 Temperature Pilot

or attempt to dismantle the thermostat

element. The system is filled with

volatile fluid which, if lost, will render the

pilot inoperative.

Dismantling

1. Remove diaphragm nuts (key 4) and lift off top

works and diaphragms.

2. Remove the blind flange bolts (key 7) and

take off the blind flange (key 26). Remove the

screen (key 46) and gasket (key 45 ).

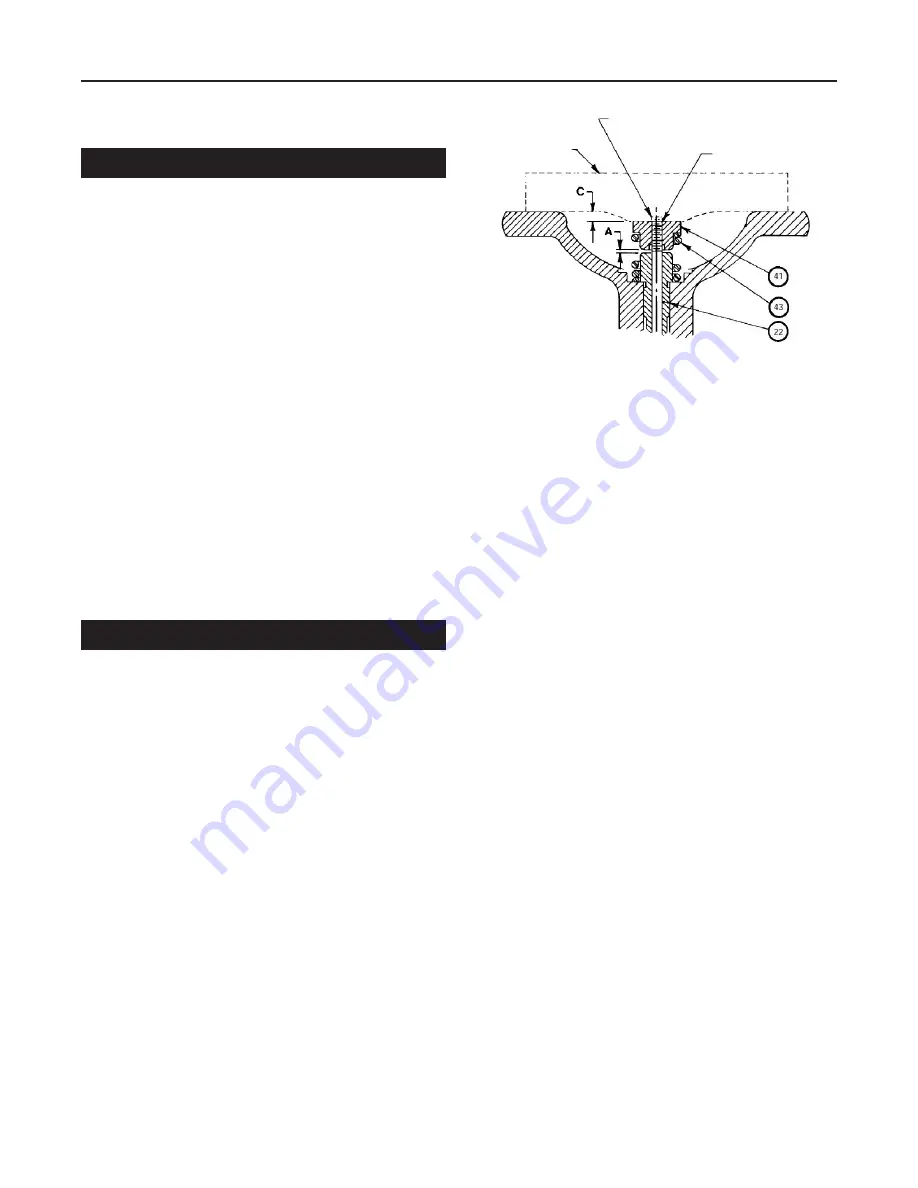

3. Hold the pusher plate (key 41) with a socket

wrench and remove stem nuts (key 25). The disk

(key 24) will drop off.

4. Lift out the stem (key 22) and valve spring

(key 43).

Assembly

1. Reassemble the pilot in the reverse of the

Dismantling procedure.

2. Ensure that diaphragm screw (key 37) and cowl

bracket (key 19) are centered on diaphragm flange

of the pilot body (key 44). Misalignment can cause

erratic performance.

3. When replacing diaphragms, apply sealing

compound (High pressure, high-temperature

sealant) sparingly to the shoulder of the diaphragm

screw (key 37). For steel pilot only, apply sealing

compound to the diaphragm flange of the

pilot body.

Seat, Disk and Stem Replacement

1. Examine the seat and disk sealing surfaces for

nicks or other signs of damage by pipeline debris.

Replace the sealing surfaces if damaged.

2. When seat or disk is replaced, ensure that the

sealing surfaces are lapped. After the sealing

surfaces are lapped in, disassemble and clean

all parts.

Note

Lap sparingly using 500 grit lapping

compound and light pressure. Heavy

grinding may cause galling, wide sealing

surfaces and a grooved disk, all of which

tend to produce leakage.

Figure 5

. Travel Setting

GAGE

PRICK PUNCH

STEM PROJECTION "B" TO BE

REMOVED AS PER INSTRUCTIONS

6

Types T124 and T134