Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation

Parameters

Technical

data

Component

sizing

Diagnostics

30

Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

4 System design

4.1 Introduction

The sizing of a regen system must take into account the following

factors:

1. Line voltage variation

2. Motor rated current, rated voltage and power factor

3. Maximum required power and overload requirements

4. Heavy Duty / Normal Duty Regen drive ratings

In general, when designing a regen system, equal Regen and motoring

drive rated currents will work correctly. However, care must be taken to

ensure that under worst case supply conditions the Regen drive is able

to supply / absorb all the required power including total system losses.

If the Regen drive is unable to supply the full power required by the

motoring drive(s), the DC bus voltage will drop, and in severe cases may

lose synchronisation with the AC supply and trip. If the Regen drive is

unable to regenerate the full power from the motoring drive(s) into the

DC bus, then the Regen drive and motoring drive(s) will trip on over-

voltage.

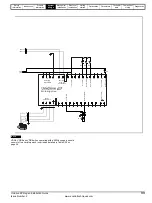

4.1.1 Single Regen, single motoring drive

The following calculations can be carried out for either a single Regen

drive, motoring drive system or single Regen drive, multiple motoring

drive system.

Example

In the case of a 23A (

Normal Duty

), SP2403 operating in regen mode

from a 400V supply, and a SP2403 driving a 400V rated, 0.85 pf motor:

The rated power of the Regen drive is:

=

1.73

x

23

x

400

=

15.9kW

The motoring drive can supply power:

=

1.73

x

23

x

400

x

0.85

=

13.5kW

Drive losses

2 x Unidrive SP 2403 = 626W

When the motoring drive is supplying rated current to the motor, the

Regen drive needs to provide 13.5kW, plus drive losses = 14.126kW.

The Regen drive can supply 15.9kW at rated current, which is ample, in

this case.

Conversely, in some cases, a Regen drive of the same rating as the

motoring drive, may not be able to supply enough power, as the

following example shows:

Example

In the case of a 96A (

Heavy Duty

), SP4403 operating in regen mode,

and a SP4403 driving a 75kW, 400V, 0.95pf motor:

If the motoring drive is supplying 175% maximum current, and the

Regen drive has its 380V supply at the lower limits of -10% (342Vac),

then, with a regen current limit of 150%:

The Regen drive maximum available power is:

=

1.73

x

1.5

x

96

x

342

=

85.1kW

The motoring drives maximum. power is:

=

1.73

x

1.75

x

96

x

400

x

0.95

=

110.4kW

Drive losses

2 x Unidrive SP 4403 = 1.952kW

The Regen drive is also required to supply the Regen and motoring drive

losses in this example 1.952kW which brings the total power

requirement to 112.352kW. However, this Regen drive is only capable of

supplying approximately 85.1kW and therefore a drive of a larger rating

is required.

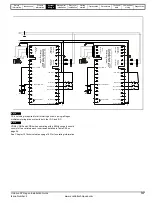

4.1.2 Multiple motoring drives

In multi-drive configurations, the Regen drive must be of a sufficient size

to supply the net peak power demanded by the combined load of all

motoring drives plus the combined losses, including its own losses.

Due to the effects of increased DC bus capacitance, there is a limit to the

number of motoring drives that can be supplied from a Regen drive. This

is true irrespective of the balance of power between the motoring drives

and the Regen drive.

The previous calculations can be used for the sizing of multiple motoring

drives also.

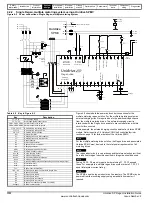

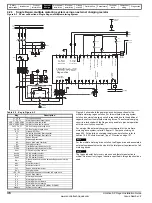

4.2 Power connections

The following section covers the power connections required for

Unidrive SP regen systems.

•

For single Regen, single motoring systems, AC supply connections

are made to L1, L2 and L3 drive terminals and the drive’s internal

soft start circuit is used for power-up.

•

The single Regen, multiple motoring and multiple regen, multiple

motoring systems require an external charging circuit due to the

extra capacitance from the additional drives. No AC connections are

made to the Regen drive’s L1, L2 and L3 terminals. The external

charging circuit can consist of either the SPMC solution or an

external charging resistor as shown in the following.

•

For the regen brake resistor replacement system, the motoring

drive’s internal soft start is used for power-up with no AC

connections to L1, L2, L3 on the Regen drive.

For control circuit connections refer to section 6.6

If the regen system is not a standard configuration or changes are

required to the following systems and set ups, contact the supplier of the

drive.

3 Rated current

×

Supply voltage

×

3 Rated current

×

Motor voltage Power factor

×

×

3 150% Rated current

×

×

Supply voltage

×

3 175% Rated current

×

Motor voltage

×

×

Power factor

×

NOTE

Содержание SP1201

Страница 219: ......

Страница 220: ...0471 0029 02 ...