6

PENBERTHY

LED ILLUMINATOR FOR FLAT GLASS GAUGES, HAZARDOUS LOCATION

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

7.3 Troubleshooting

1. Internal or external corrosion could be an

indication of a harsh service environment.

An investigation should immediately be

carried out to determine the cause of the

problem. It is the user’s responsibility

to choose a material of construction

compatible with both the contained fluid

and the surrounding atmosphere.

2. All LED’s off could be an indication of

power failure. Check the power supply

and connections.

IMPORTANT

Contact manufacturer if any part needs to be

replaced.

7.4 Allowable modifications

The LED illuminator are not to be modified in

any way. Any modifications will void warranty

and could result in equipment damage or

serious personal injury.

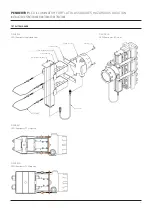

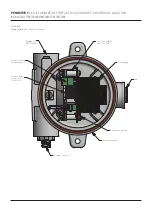

8 REMOVAL - DISASSEMBLY - REASSEMBLY

8.1 Disassembly

Refer to the exploded parts diagram in

Sections 13-15 for additional reference during

disassembly and reassembly of the illuminator.

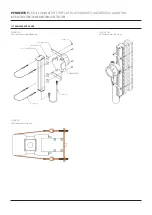

Transparent gauge

1. Disconnect the electrical power source

from the illuminator.

2. Hold the illuminator firmly. Loosen the wire

assembly. Completely remove the eyebolts

from the plate bracket (one side only).

3. Move wires out of the way and remove the

illuminator.

Reflex gauge

1. Disconnect the electrical power source

from the illuminator.

2. Hold the illuminator firmly. Remove the

screws on the back of the illuminator body

that hold the mounting bracket.

3. Remove the illuminator from the mounting

bracket.

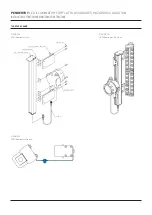

TSL/TSM gauge

1. Disconnect the electrical power source from

the illuminator

2. Hold the illuminator firmly. Loosen the wire

assembly. Completely remove the eyebolts

for the plate bracket (only side only).

3. Move wires out of the way and remove the

illuminator.

7.2 Maintenance procedures

Cleaning the protective glass - wash with a

non-abrasive soap or detergent and water

using a soft, grit-free cloth or sponge. When

cleaning grease and oil from the protective

glass, use a chemical compatible with

silicone rubber only and a soft, grit-free cloth.

DO NOT use solvents such as acetone,

benzene, carbon tetrachloride, dry cleaning

fluid or lacquer thinners since they will attack

the surface of the protective glass and or the

gaskets. After surface has been cleaned and

rinsed of foreign particles, it may be dried with

a clean, soft, damp chamois or grit-free cloth.

IMPORTANT

DO NOT use hard, rough cloths on edge of

protective glass because they can scratch the

surface. The scratches will result in reduced

light output from the illuminator.

6 OPERATION

Check that all installation procedures

have been completed. Use only qualified,

experienced personnel who are familiar with

illuminators and thoroughly understand the

implications of all the instructions. If the

equipment is used in a manner not specified by

the manufacturer, the protection provided by

the equipment may be impaired.

7 MAINTENANCE

The user must create maintenance schedules,

safety manuals, and inspection details for each

specific installation of an illuminator.

7.1 Preventative maintenance

On all installations the following items should

be regularly evaluated by the user for purposes

of maintenance:

1. Protective glass, for signs of dirt build up,

scratches or breakage.

2. Mounting bracket for signs of loosening.

The user must determine upon evaluation of his

or her own operating experience an appropriate

maintenance schedule necessary for his or

her specific application. Realistic maintenance

schedules can only be determined with full

knowledge of the services and application

situation involved.