Instruction Manual

D200149X012

3610J and 3620J Positioners

September 2017

20

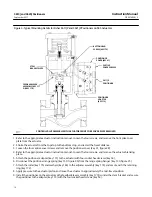

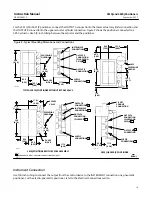

Figure 8. Typical Mounting Dimensions and Connections (Continued)

19A1486‐C

11B2613‐C

B2151‐2

208

(8.19)

146

(5.75)

93.0

(3.66)

63.5

(2.50)

63.5

(2.50)

63.5

(2.50)

146

(5.75)

50.8

(2.00)

100

(3.95)

208

(8.19)

87.4

(3.44)

153.9

(6.06)

49.3

(1.94)

3621JP POSITIONER

3611JP POSITIONER

SUPPLY

CONNECTION

OUTPUT B

CONNECTION

SUPPLY

CONNECTION

OUTPUT B

CONNECTION

OUTPUT A

CONNECTION

INSTRUMENT

CONNECTION

OUTPUT A

CONNECTION

1/2 NPT

CONDUIT

CONNECTION

NOTE:

1INSTRUMENT, OUTPUT, AND SUPPLY CONNECTIONS ARE 1/4 NPT

3622 I/P

CONVERTER

GAUGE

BLOCK

CENTERLINE

OF BODY

17.5

(0.69)

1

1

1

1

1

1

1

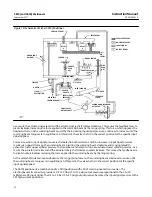

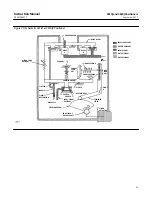

Diagnostic Connections

To support diagnostic testing of valve/actuator/positioner/accessory packages, special connectors and hardware are

available. The hardware used includes 1/8 NPT connector bodies and body protectors. If the diagnostic connectors are

ordered for a positioner with gauges, 1/8‐inch stems are also included.

Install the connectors on the 3610J positioner gauge block or bypass block assembly as shown in figure 9. For 3620J

positioners, install the connectors on the 3622 housing as shown in figure 10. Before installing the connectors on the

positioner, apply sealant to the threads. Sealant is provided with the diagnostic connections and hardware.