26

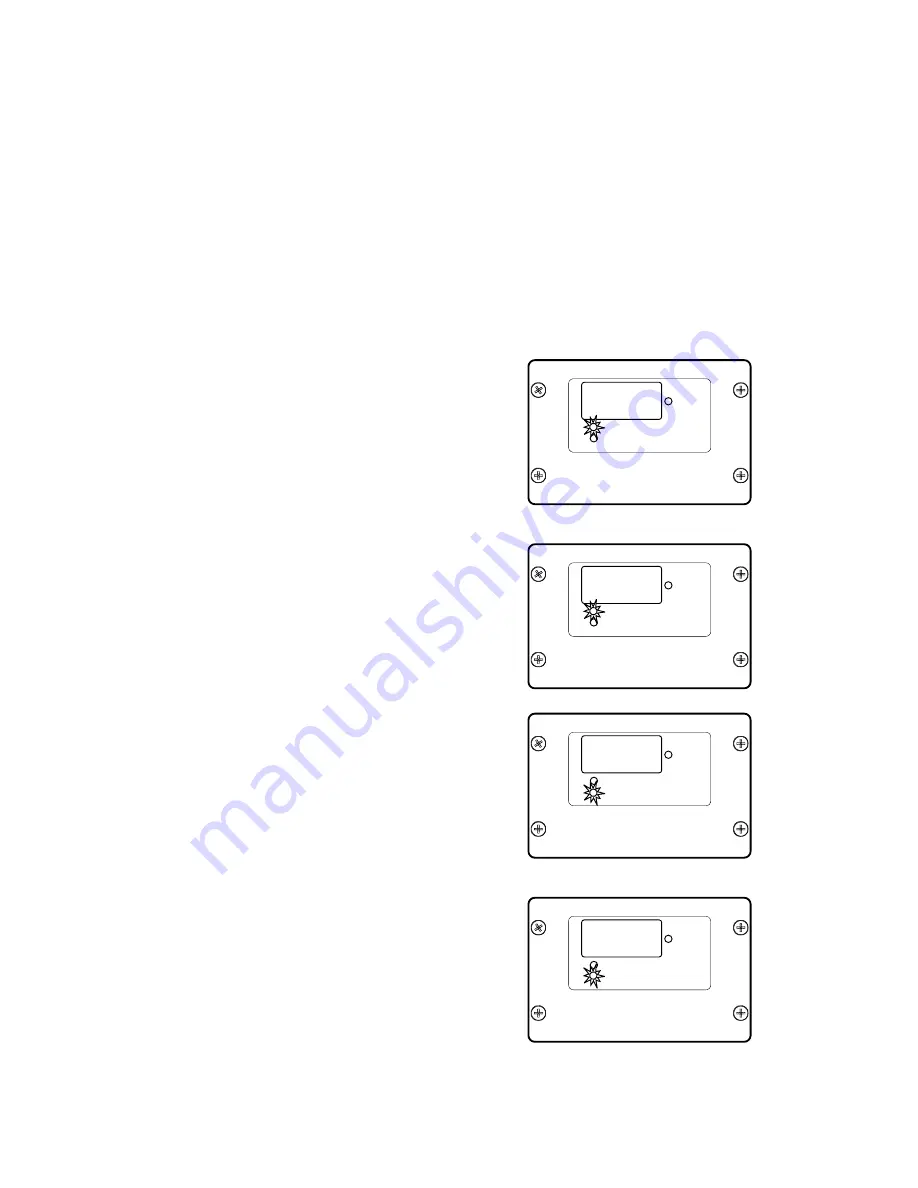

1. Programming Upper RPM Limit (Ceiling):

• Press mode button twice. Digital readout will

display current upper limit setting. This repre-

sents the RPM at which the Rapid Recovery

Auto Reverse will re-start the feed rolls after

a suspension.

•

Oil Use indicator will flash. Increase or de

-

crease setting using program buttons (factory

setting is 1375 RPM)

2. Programming Upper Flow Percentage:

• Press mode button once more. Digital read-

out will display current upper flow setting. This

represents the percent of hydraulic flow that

will be sent to the feed rolls (Feed speed.).

•

Oil Use indicator will flash. Increase or de

-

crease setting using program buttons, do not

set above 80 % (factory setting is 75%)

3. Programming Lower RPM Limit (Floor) :

• Press mode button once more. Digital rea-

dout will display current lower limit setting.

This represents the rotor RPM at which the

Rapid Recovery Auto Reverse will reverse

and suspend the feed rolls.

•

Machine hours indicator will flash. Increase

or decrease setting using program buttons.

(factory setting is 900 RPM)

4. Programming Lower Flow Percentage:

• Press mode button once more. Digital read-

out will display current lower flow setting. This

represents the percent of hydraulic flow that

will be sent to the feed rolls (Feed speed.).

•

Machine hours indicator will flash. Increase

or decrease setting using program buttons,

do not set below 25% (factory setting is 35%)

8888

ROTOR

R. P. M.

OIL USE HOURS

MACHINE HOURS

EMB MFG INC.

8888

ROTOR

R. P. M.

OIL USE HOURS

MACHINE HOURS

EMB MFG INC.

8888

ROTOR

R. P. M.

OIL USE HOURS

MACHINE HOURS

EMB MFG INC.

8888

ROTOR

R. P. M.

OIL USE HOURS

MACHINE HOURS

EMB MFG INC.

1

375

88

75

0

900

88

35

4.4.2 INTELLIFEED PROGRAMMING:

The factory settings provide good overall performance for the CR70, however you may under certain

circumstances, choose to customize performance. (controller is accessible through the battery access

door.) Programmable features of Intellifeed include: the upper and lower RPM limits (rotor speed) and

the upper and lower flow percentage (roller speed).

How best to adjust the programming will come from experience and common sense, if in doubt set to

factory setting for optimum performance.

Here are some helpful hints:

•

For heavier brush, decrease the upper flow percentage for slower feed speed.

•

For lighter brush, increase the upper flow percentage for faster feed speed.

•

If the chipper is stalling before the feed rolls stop, increase the rotor floor setting.

•

If you prefer more aggressive feeding with faster feed and more stops, increase the lower flow

percentage.

Содержание Wallenstein CR Series

Страница 69: ...69 ...