ENGLISH

5

WARNING

CAREFULLY READ THE INSTALLATION OPERA-

TING AND MAINTENANCE INSTRUCTIONS BEFORE

INSTALLING THIS APPLIANCE. INCORRECT

INSTALLATION, ADAPTATIONS OR ALTERNATIONS

COULD CAUSE DAMAGE TO PROPERTY OR PER-

SONAL INJURY. FAILURE TO COMPLY WITH THESE

INSTRUCTIONS, ABUSE RESULTING IN DAMAGE

AND IMPROPER INSTALLATION WILL VOID WAR-

RANTY AND RESPONSIBILITIES OF THE MANUFAC-

TURER.

1. Carefully read this instructions booklet, as it contains

important advice for safe installation, operation and

maintenance. Keep this booklet handy in a safe place

for future reference.

2. The installation instructons contained herein are

for the use of qualified installation and service

personnel only. Installation or service by other

than qualified personnel may result in damage to

the appliance and/or injury to the operator. FAIL-

URE TO COMPLY WITH INSTALLATION

INSTRUCTION OR IMPROPER INTALLATION

WILL VOID WARRANTY AND RESPONSIBLITIES

OF THE MANUFACTURE.

3. The equipment warranty is not valid unless the unit is

installed, started and demonstrated under the super-

vision of a factory trained installer.

4. Switch off the appliance in the event of failure or mal-

functioning at the main circuit breaker.

Only have the appliance repaired by an Authorized Ser-

vice Center and be sure to ask for OEM original spare

parts.

NOTICE FOR SHIPPING DAMAGE

•

The container should be examined for damage

before and during unloading.

•

The freight carrier has assumed responsibility for its

safe transit and delivery.

•

If damaged equipment is received, either apparent or

concealed, a claim must be made with the delivering

carrier. Apparent damage or loss must be noted on

the freight bill at the time of delivery.

•

The freight bill must then be signed by the carrier

representative (Driver). If the bill is not signed, the

carrier may refuse the claim. The supply can supply

the necessary forms.

•

A request for inspection must be made to the carrier

within 15 days if there is concealed damage or loss

that is not apparent until after the equipment is uncra-

ted. The carrier should arrange an inspection.

•

Be certain to hold all contents plus all packing mate-

rial. Under no circumstances should a damaged

appliance be returned to the manufacturer without

prior notice and written authorization.

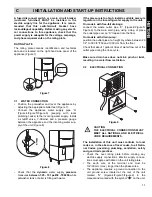

B1

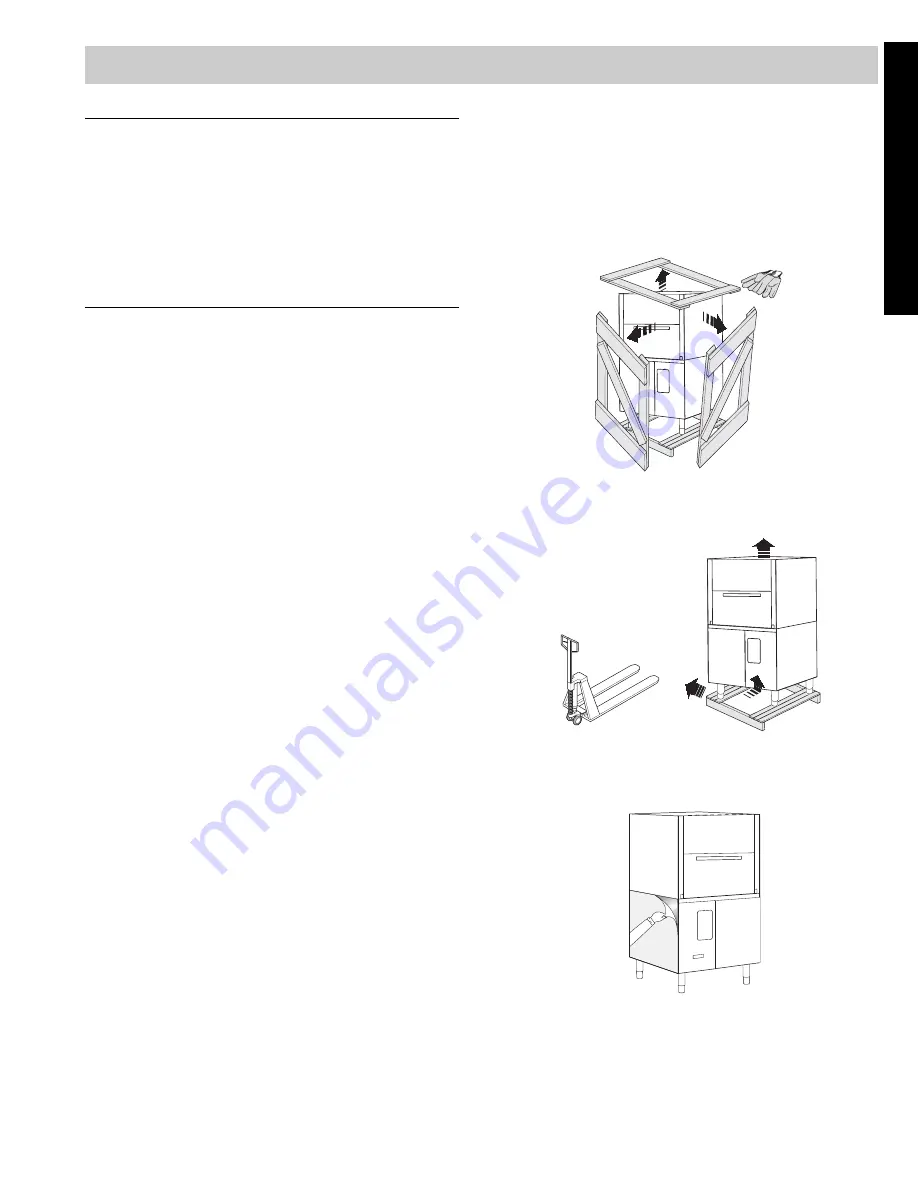

HANDLING

Use suitable means to move the appliance: a lift truck or

fork pallet trucks (the forks should reach more than hal-

fway beneath the appliance).

B2

UNPACKING

Wear protective gloves to unpack.

Figure 1

Lift the appliance using a lift truck,

Figure 2

remove the base and position the appliance where it is

to be installed.

Figure 3

Remove the protective film and ensure that the packag-

ing material is disposed of correctly in compliance with-

the regulations in force in the country where the product

is to be used.

B

GENERAL RECOMMENDATIONS