ELKM43

CONTROLLER AND

MINI-PROGRAMMER

Quick guide

ELKM43-GB-06-05-B

EL.CO. S.r.l.

Via Lago di Molveno, 20 - 36015 Schio (VI)

ITALY

Tel.: +39 0445 661722 - Fax: +39 0445 661792

www.elco-italy.com

e-mail: [email protected]

Preface

m

This manual contains the information necessary for

the product to be installed correctly and also in-

structions for its maintenance and use; we therefore

recommend that the utmost attention is paid to the

following instructions and to save it.

This document is the exclusive property of eL.cO. S.r.l.

which forbids any reproduction and divulgation, even

partially, of the document, unless expressly authori-

zed. eL.cO. S.r.l. reserves the right to make any formal

or functional changes at any moment and without

notice.

eL.cO. S.r.l. and its legal representatives do not assume

any responsibility for any damage to people, things or

animals deriving from violation, wrong or improper

use or in any case not in compliance with the instru-

ment features.

m

Whenever a failure or a malfunction of the control

device may cause dangerous situations for persons,

thing or animals, please remember that the plant

has to be equipped with additional safety devices.

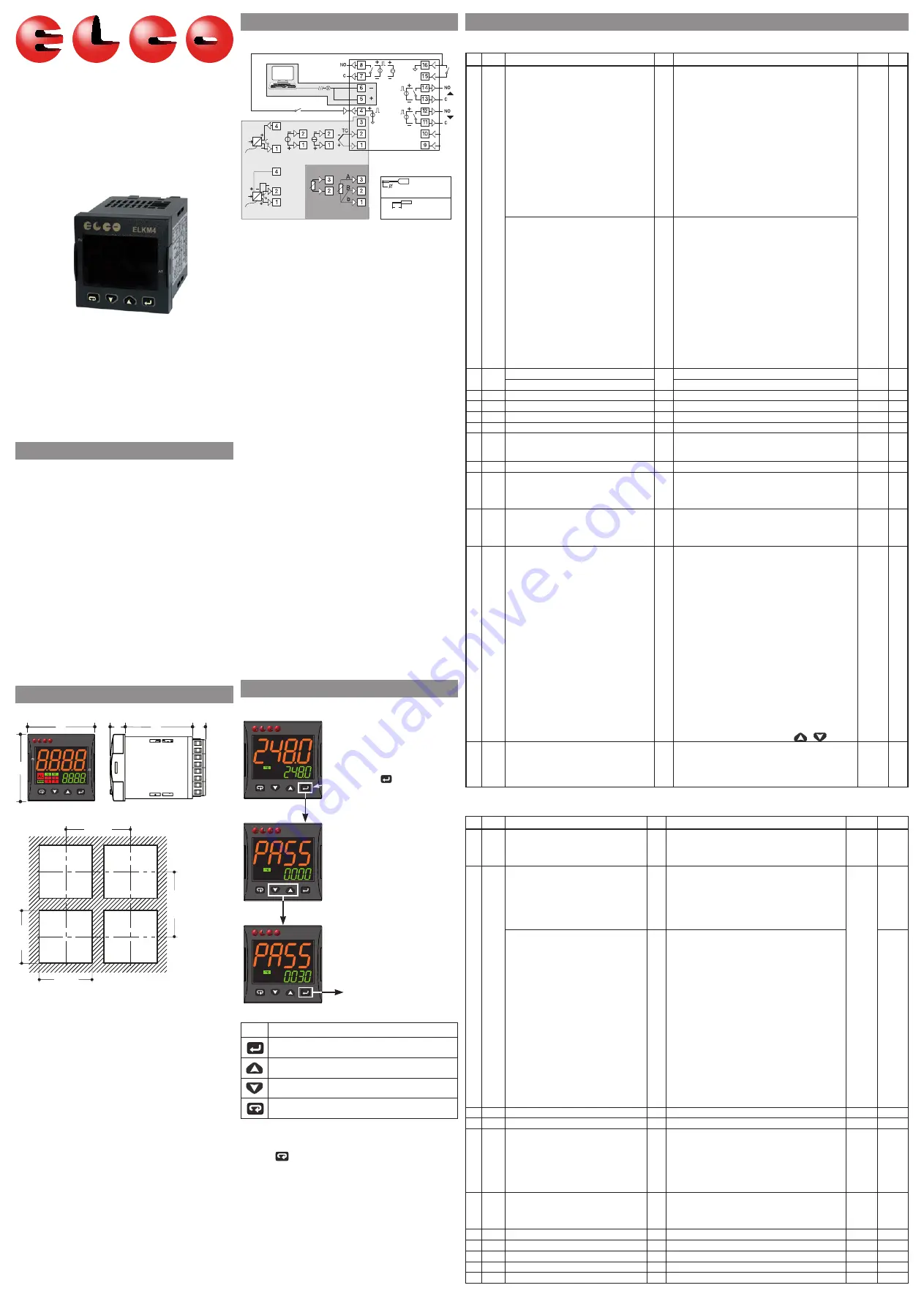

1. dIMeNSIONS aNd cuT-OuT (mm)

controller with non removable terminals

48

48

48

11

14

Panel cut-out

65 mm min.

45

+0.6

mm

45

+0.6

mm

65 mm min.

Mounting requirements

This instrument is intended for permanent installa-

tion, for indoor use only, in an electrical panel which

encloses the rear housing, exposed terminals and

wiring on the back. Select a mounting location having

the following characteristics:

1. It should be easily accessible;

2. There is minimum vibrations and no impact;

3. There are no corrosive gases;

4. There are no water or other fluids (i.e. condensation);

5. The ambient temperature is in accordance with the

operative temperature (0... 50°c);

6. The relative humidity is in accordance with the

instrument specifications (20... 85%);

The instrument can be mounted on panel with a

maximum thickness of 15 mm.

When the maximum front protection (IP65) is desired,

the optional gasket must be mounted.

2. eLecTrIcaL cONNecTIONS

eLecTrIcaL cONNecTIONS

RS485

Thermo-

couple

DI1

OP3

OP2

OP1

OP4

(note)

DI2 (note)

Analogue input

mV, V

mA

12 VDC

(note)

PV

4... 20 mA

3 wire transmitter

12 VDC

(note)

PV

Pt100

Pt1000/NTC/PTC

4... 20 mA

2 wire transmitter

Neutral

Line

Power

supply

Terminals

Pin:

q

1.4 mm max. (0.055 in.)

Stropped wire: L: 5.5 mm (0.21 in.)

L

Note: Terminal 4 can be programmed as:

- digital Input (dI2) connecting a free of voltage

contact between terminals 4 and 16;

- 0... 12 V SSr drive Output (OP4) connecting the load

between terminals 4 and 16;

- 12 Vdc (20 ma) transmitter power supply connect-

ing the 2 wire transmitter between terminals 4

and 1; for 3 wire transmitter connect terminal

4 to transmitter power supply input and termi-

nal 1 and 2 to transmitter signal output.

Power supply voltage: 100... 240 Vac/20... 30 Vdc/

18... 28 Vac/24... 240Vac/dc;

Out1 relay: 4 (4) a/250 Vac, SPST;

Out2, 3 relay: 2 (1) a/250 Vac, SPST Na (*) ;

Out1, 2, 3 SSr: 10 Vdc/15 ma;

Linear Out1: 0/4... 20 ma, 0/2... 10 V;

Out4 SSr:

12 Vdc/20 ma.

* for

eLKM43 servodrive models both Out2 and Out3

are to be selected as “M” in configuration code;

Out2: open, Out3: close.

General notes about wiring

1. Safety regulations require a line switch marked as

instrument disconnecting device. This switch must

be easily reachable by the operator;

2. do not run input wires together with power cables;

3. external components (like zener barriers, etc.) con-

nected between sensor and input terminals may cause

errors in measurement due to excessive and/or not

balanced line resistance or possible leakage currents;

4. When a shielded cable is used, it should be con-

nected at one point only;

5. Pay attention to the line resistance, a high line

resistance may cause measurement errors.

6. To avoid electrical shocks, connect power line at last;

7. Before connecting the instrument to the power

line, make sure that line voltage is equal to the

voltage shown on the identification label;

8. The power supply input is NOT fuse protected.

Please, provide an external fuse T type 1a, 250 V.

3. cONfIGuraTION PrOcedureS

Setting the parameters

Press the key

for 3 seconds

Access to

parameters

Insert

password

(default: 30)

PV

AT

PV

AT

PV

AT

Key

editing Mode

confirm and go to Next parameter

Increase the displayed value or select the next element

decrease the displayed value or select the previous element

exit from Operator commands/Parameter setting/configuration

How to exit the “configuration mode”

To exit from the configuration mode,

press the

key for 3 seconds.

code configuration procedure

for eLKM43 version (without timer and programmer) a

simplified code configuration method is available. Only

essential functions can be set up with code configura-

tion procedure. See the “engineering user Manual” for

more details.

4. LIST Of THe ParaMeTerS (

pAss

: 30)

]

inP Group - Main and auxiliary input configuration

no. Par.

description

dec.

Values

default Notes

SenS

Model c

J

Tc J

(-50... +1000°c/-58... +1832°f);

craL Tc K

(-50... +1370°c/-58... +2498°f);

S

Tc S

(-50... 1760°c/-58... +3200°f);

r

Tc r

(-50... +1760°c/-58... +3200);

t

Tc T

(-70... +400°c/-94... +752°f);

Ir.J exergen IrS J (-46... +785°c/-50... +1445°f);

Ir.ca exergen IrS K (-46... +785°c/-50... +1445°f);

Pt1 rTd Pt 100 (-200... +850°c/-328... +1562°f);

Pt10 rTd Pt 1000 (-200... +850°c/-328... +1562°f);

0.60 0... 60 mV linear;

12.60

12... 60 mV linear;

0.20 0... 20 ma linear;

4.20 4... 20 ma linear;

0.5 0... 5 V linear;

1.5 1... 5 V linear;

0.10 0... 10 V linear;

2.10 2... 10 V linear.

J

Model e

J

Tc J

(-50... +1000°c/-58... +1832°f);

craL Tc K

(-50... +1370°c/-58... +2498°f);

S

Tc S

(-50... 1760°c/-58... +3200°f);

r

Tc r

(-50... +1760°c/-58... +3200);

t

Tc T

(-70... +400°c/-94... +752°f);

Ir.J exergen IrS J (-46... +785°c/-50... +1445°f);

Ir.ca exergen IrS K (-46... +785°c/-50... +1445°f);

Ptc PTc KTY81-121 (-55... +150°c/-67... +302°f);

ntc NTc 103-aT2 (-50... +110°c/-58... +230°f);

0.60 0... 60 mV linear;

12.60

12... 60 mV linear;

0.20 0... 20 ma linear;

4.20 4... 20 ma linear;

0.5 0... 5 V linear;

1.5 1... 5 V linear;

0.10 0... 10 V linear;

2.10 2... 10 V linear.

2

dp

decimal Point Position (linear inputs)

0

0... 3

0

decimal Point Position (non linear inputs)

0/1

3

SSc Initial scale read-out for linear inputs

dp -1999... 9999

0

4

fSc

full Scale readout for linear inputs

dp -1999... 9999

1000

5

unit engineer unit

°c/°f

°c

6

fil

digital filter on the measured value

1

0 (= Off)... 20.0 s

1.0

7

ine

Sensor error used to enable the safety output

value

or

Over range;

ur

under range;

our

Over and under range.

our

8

oPe Safety output value (% of the output)

-100... 100

0

9

IO4.f I/O 4 function

on

Output used as PWS for TX;

out4 Output 4 (digital output 4);

dG2c digital input 2 driven by contact;

dG2u digital input 2 driven by voltage.

out4

9

IO4.f I/O 4 function

on

Output used as PWS for TX;

out4 Output 4 (digital output 4);

dG2c digital input 2 driven by contact;

dG2u digital input 2 driven by voltage.

out4

10 dif1 digital Input 1 function

off Not used;

1

alarm reset;

2

alarm acknowledge (acK);

3

Hold of the measured value;

4

Stand by mode;

5

Manual mode;

6

Heat with SP1 and cooL with SP2;

7

Timer ruN/Hold/reset;

8

Timer run;

9

Timer reset;

10

Timer run/Hold;

11

Timer run/reset;

12

Timer run/reset with lock;

13

Program Start;

14

Program reset;

15

Program Hold;

16

Program run/Hold;

17

Program run/reset;

18

Sequential SP selection;

19

SP1 - SP2 selection;

20

SP1... SP4 binary selection;

21

digital inputs in parallel to

/

keys.

off

12 di.a digital input action (dI2 only if configured)

0

dI1 direct action, dI2 (if configured) direct action;

1

dI1 inverse action, dI2 (if configured) direct action;

2

dI1 direct action, dI2 (if configured) inverse action;

3 dI1 inverse action, dI2 (if configured) inverse

action.

0

]

Out group - Output parameters

no. Par.

description

dec.

Values

default Notes

13 o1t

Output 1 type (when Out 1 is a linear

output)

0-20 0... 20 ma;

4-20 4... 20 ma;

0-10 0... 10 V;

2-10 2... 10 V.

0-20

14 o1f

Out 1 function (when Out 1 is a linear

output)

0

None Output not used;

H.reG Heating output;

c.reG cooling output;

r.inP Measure retransmission;

r.err

error (SP - PV) retransmission;

r.SP

Set point retransmission;

r.Ser Serial value retransmission.

H.reG

Out 1 function (when Out1 is a digital

output)

0

None Output not used;

H.reG Heating output;

c.reG cooling output;

aL

alarm output;

t.out Timer output;

t.Hof Timer out -Off in hold;

P.end Program end indicator;

P.HLd Program hold indicator;

P.uit

Program wait indicator;

P.run Program run indicator;

P.et1 Program event 1;

P.et2 Program event 2;

or.bo Out of range or burn out indicator;

P.faL Power failure indicator;

bo.Pf Out of range/burn out/Power failure indicator;

St.bY Stand by status indicator;

dif.1

The output repeats the digital input 1 status;

dif.2

The output repeats the digital input 2 status;

on

Out 1 always ON;

riSP

Inspection request.

15 ao1L Initial scale for the analog retransmission dP -1999 ... ao1H

-1999

16 ao1H full scale for the analog retransmission dP ao1L ... 9999

9999

17 o1aL alarms linked up with the out 1

0

0... 63:

+1

alarm 1;

+2

alarm 2;

+4

alarm 3;

+8 Loop break alarm;

+16 Sensor Break;

+32 Overload on output 4.

1

18 o1ac Out 1 action

0

dir

direct action;

reu

reverse action;

dir.r

direct with reversed Led;

reu.r reverse with reversed Led.

dir

19 o2f Out 2 function

0

See O1f - Out 1 function (digital output)

aL

20 o2aL alarms linked up with the out 2

0

See O1aL - alarms linked up with the out 1

1

21 o2ac Out 2 action

0

See O1ac - Out 1 action

dir

22 o3f Out 3 function

0

See O1f - Out 1 function (digital output)

aL

23 o3aL alarms linked up with the out 3

0

See O1aL - alarms linked up with the out 1

2