EFORT INTELLIGENT EQUIPMENT CO., LTD

26

Chapter 4 Inspection and Maintenance

The overhaul is divided into daily overhaul and regular overhaul. Inspectors must prepare an

overhaul plan and carry out overhaul effectively. Please refer to the table below for the maintenance

items and maintenance cycle.

In addition, the overhaul must be carried out every 40,000 hours of work or every 8 years (which

method is the first to choose the deadline).

In addition, if the maintenance and adjustment methods are unknown, please contact the company's

service department

4.1

Preventive maintenance

According to the method described in this chapter, perform regular maintenance steps to maintain

the best performance of the robot.

4.1.1

Daily inspection

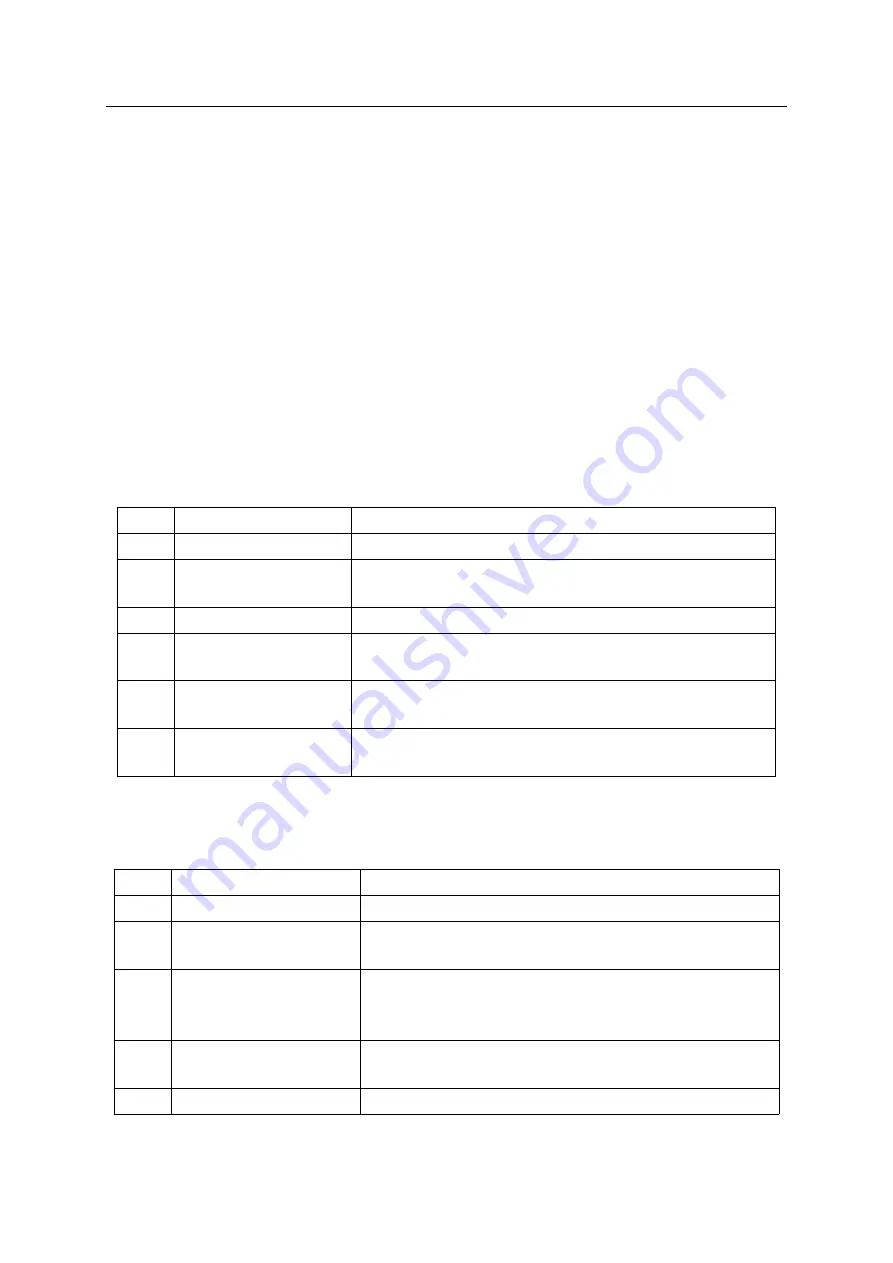

Table 4-1 Daily checklist

No Check item

checking point

1

Abnormal noise check

Check each transmission mechanism for abnormal noise

2

Interference check

Check whether each transmission mechanism is running smoothly

and whether there is abnormal jitter

3

Air cooling inspection

Check whether the fan behind the control cabinet is well ventilated

4

Inspection of pipeline

accessories

Whether it is complete and complete, whether it is worn, whether

there is corrosion

5

Peripheral electrical

accessories inspection

Check the external circuit of the robot, whether the button is

normal

6

Leak check

Check if there is any leakage of lubricating oil at the oil supply

and discharge ports

4.1.2

Quarterly inspection

Table 4-2 Quarterly checklist

No

Check item

checking point

1

Control unit cable

Check the Teach Pendant cable for improper twisting

2

Ventilation unit of control unit

If the ventilation unit is dirty, cut off the power and clean the ventilation

unit

3

Cables in the mechanical

unit

Check whether the socket of the mechanical unit is damaged,

whether it is abnormally bent, and whether the servo motor

connector and the aviation plug are connected reliably

4

Cleaning and maintenance

of various components

Check if there is a problem with the part and deal with it

5

Fastening of external main screws

Tighten the end effector screws and external main screws

Содержание ER7-700

Страница 2: ......

Страница 4: ......

Страница 7: ...ER7 700 Industrial Robot Mechanical Use and Maintenance Manual III B SPARE PARTS LIST 35 ...

Страница 8: ......

Страница 30: ...EFORT INTELLIGENT EQUIPMENT CO LTD 22 2 End tool size Figure 3 7 End tool dimensions ...