Algas-SDI Operations & Maintenance Manual P/N 52632

5-23

Maintenance

5

General

The

POWER

vaporizer is designed for long term trouble free operation. Because

of the nature of its use, and the severe duty it receives, it is important to provide

scheduled maintenance. A list of

RECOMMENDED SPARE PARTS

is located in

the back of this manual.

WARNING

To prevent injury from electric shock, disconnect the supply circuit

before servicing the unit.

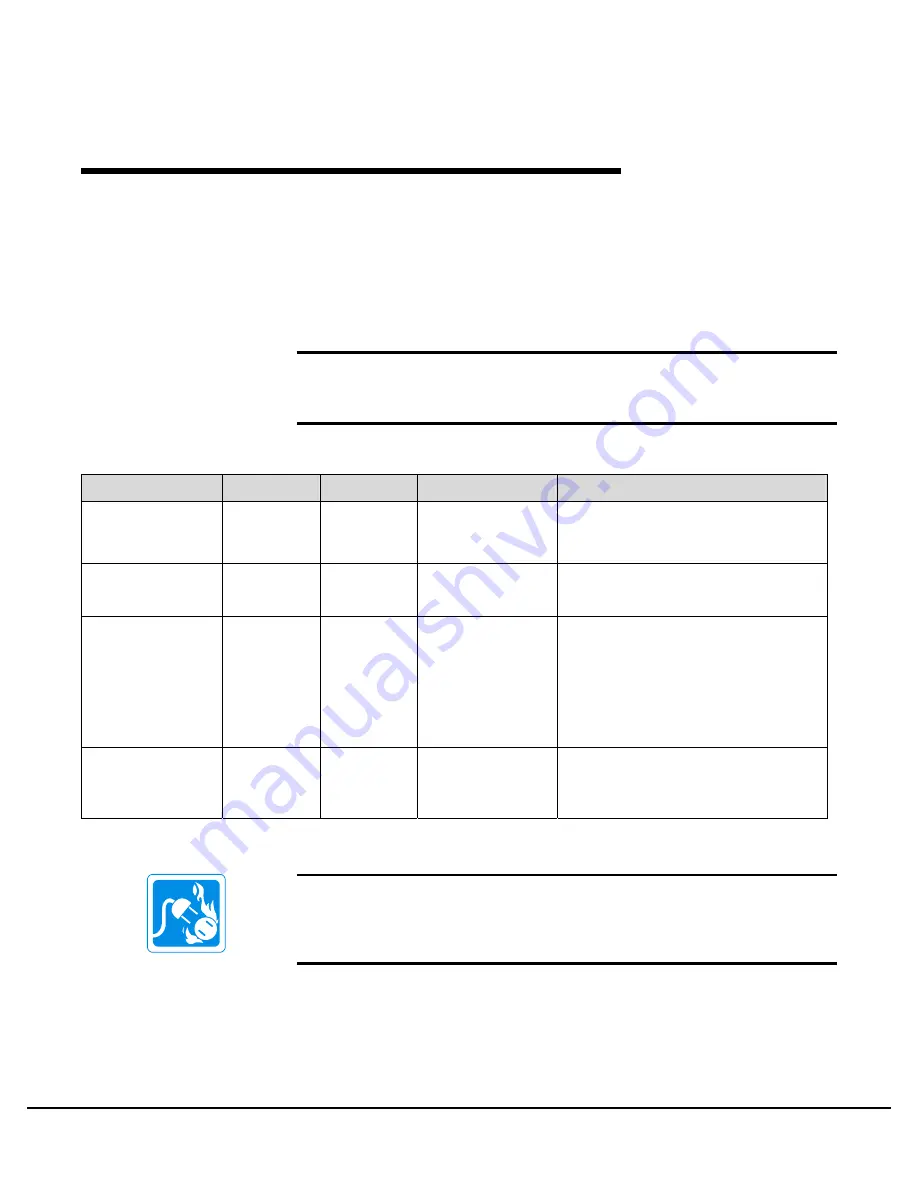

Table 3 – Maintenance Schedule

ITEM

1 MONTH

3 MONTHS

6 MONTHS

ANNUALLY

Liquid Propane

Strainer

(installed by others)

Visually

inspect and

clean.

Visually inspect and

clean.

Safety Relief Valve

Visually check.

Replace if any leakage is observed.

Inlet

Solenoid

Inspect and clean piston as necessary.

Annually change the inlet solenoid

diaphragm once per year.

See the enclosed Maintenance &

Operation sheet for ASCO 2-way

valves: Appendix A Figure 21.

Electrical Wiring and

Connections

(in control box)

Visually inspect for loose connections,

corrosion, or evidence of heating.

Replace if necessary.

NOTE

When servicing an individual unit, disconnect power at the Main

disconnect. Isolation valves in the Vapor Outlet manifold and

Liquid Inlet Manifold allows removal of individual units.