5

5 INCH CHIPPER/SHREDDER

ENGLISH

Section

2

ASSEMBLY

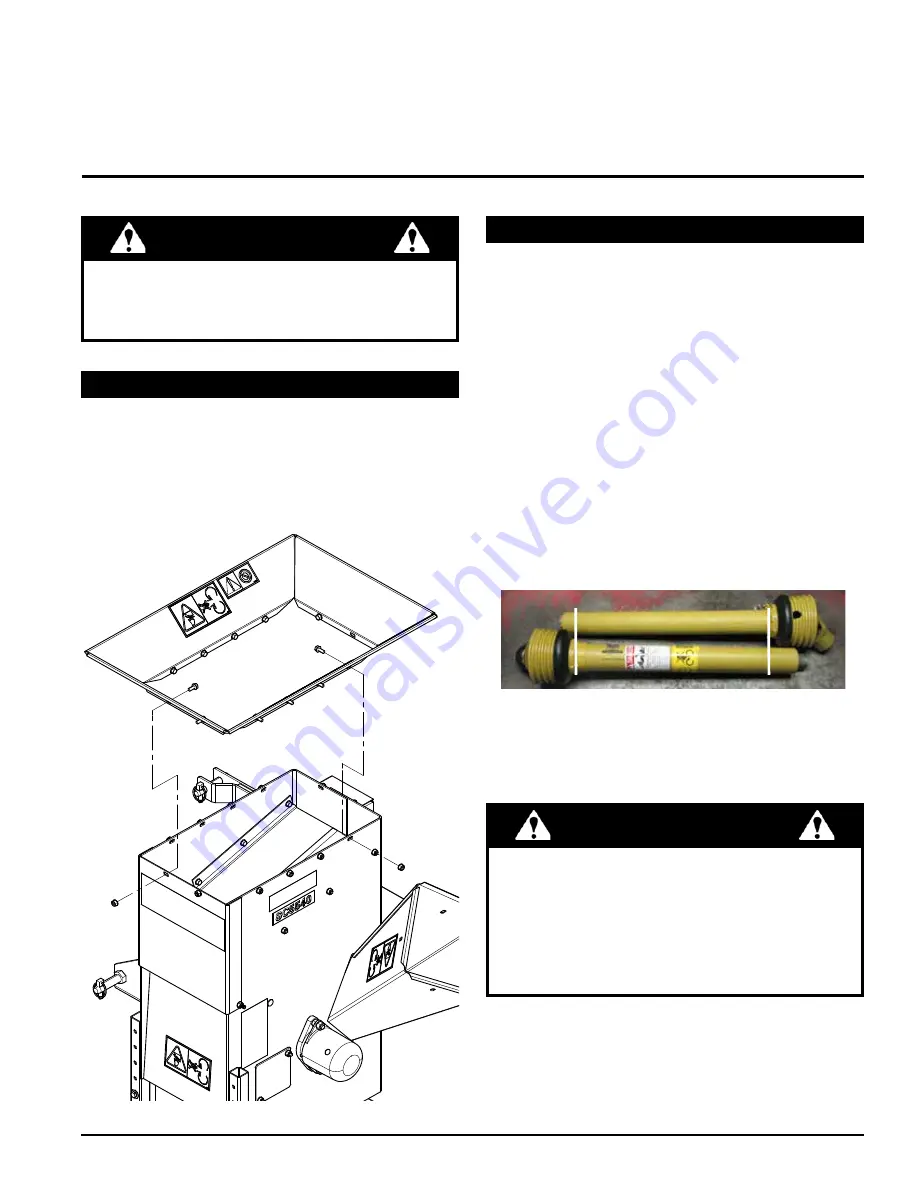

2.1 INSTALL THE HOPPER

1. Place the hopper assembly on top of the shredder

frame. The tabs on the bottom of the hopper should

be placed inside the shredder frame.

2.

Secure with eleven (11) 5/16" × 3/4" hex bolts and

nylock nuts. Insert the bolts from inside the hopper.

If any bolts or nuts are dropped in the machine, be

sure to remove them before starting the machine.

Remove items from the shredder area by removing the

discharge screen.

WARNING

2.2 CONNECT THE PTO DRIVELINE

The driveline supplied with this machine may need to be

cut to a shorter length for proper operation with the tractor

being used. To determine if driveline will need to be cut,

follow steps below or consult attached driveline manual.

1. BEFORE ATTACHING THE DRIVELINE:

attach the

machine to the tractor with three-point hitch system.

2. Raise and lower machine on three-point hitch to

determine the shortest possible working distance

between the tractor PTO shaft and the drive shaft of

the machine.

3. Pull the driveline apart so the two pieces are

separated. Attach the 6-splined connector for the

outer tube to the tractor, and attach the connector for

the inner tube to the machine.

4. Position installed driveline halves parallel to one

another. (Photo below is example of driveline overlap.)

5.

On larger outer tube, measure back 1‑1/4" (32 mm)

from lower yoke shield and mark plastic tube. Repeat

this process for smaller inner plastic tube measuring

1‑1/4" (32 mm) back from upper yoke shield.

●

The tractor must have a standard 540 RPM PTO

shaft.

●

If the tractor has an electric PTO clutch, consult

your dealer for correct operating procedures.

●

Consult the attached GKN Walterscheid driveline

manual for complete service and maintenance

recommendations.

IMPORTANT