Operating instructions

G1G170-AB05-81

Translation of the original operating instructions

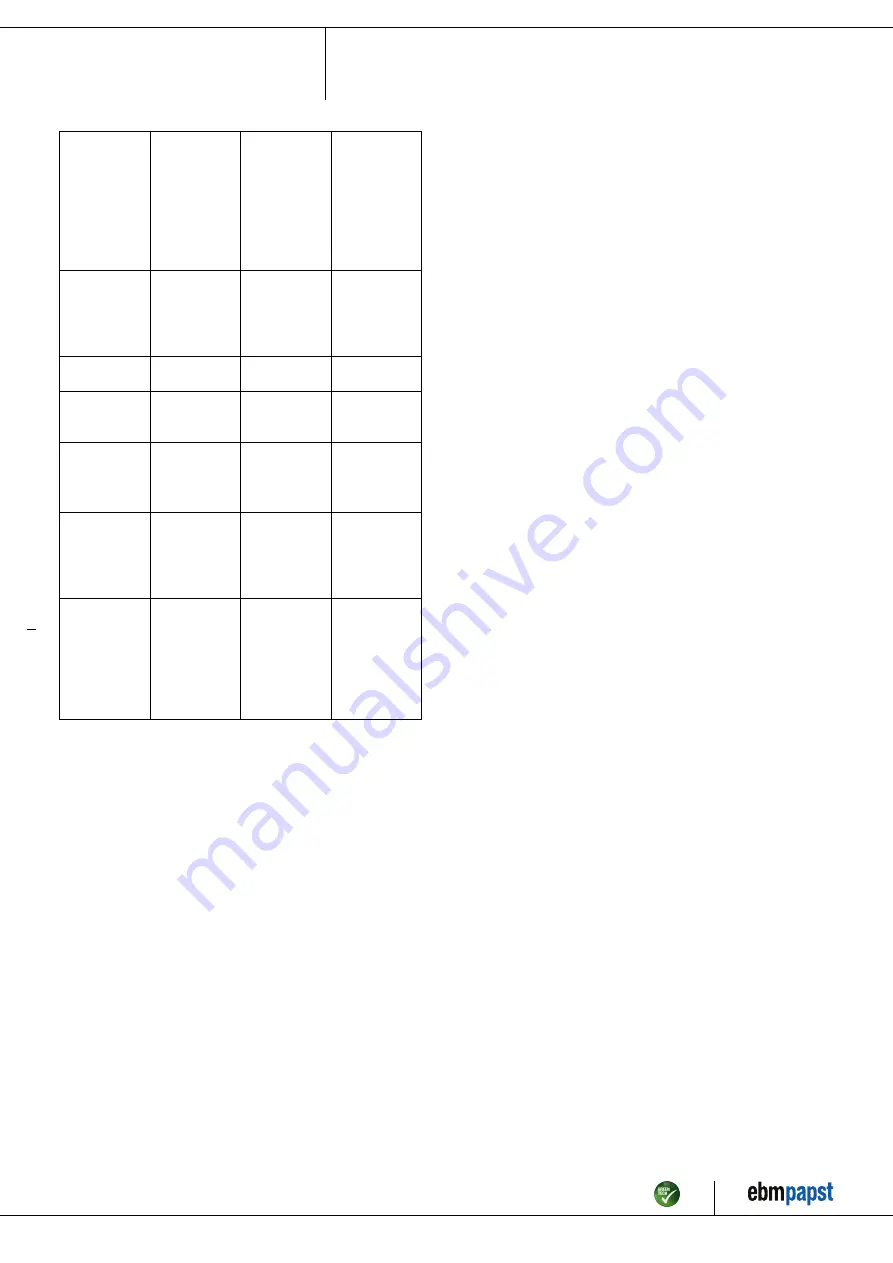

Check the

protective

casing against

accidental

contact for

damage and to

ensure that it is

intact

Visual inspection At least every

6 months

Repair or

replacement of

the device

Check the

device for

damage to

blades and

housing

Visual inspection At least every

6 months

Replacement

of the device

Mounting the

connection lines

Visual inspection At least every

6 months

Fasten

Mounting of

protective

earth connection

Visual inspection At least every

6 months

Fasten

Check the

insulation of

the wires for

damage

Visual inspection At least every

6 months

Replace wires

Condensate

discharge

holes for

clogging, as

necessary

Visual inspection At least every

6 months

Open bore holes

Check the ball

bearings to

ensure they

are quiet, can

move easily

and are free of

play

Manual check

by turning the

rotor in shut-off

state

At least every

6 months

Replace

device in case

of noise,

difficulty of

movement or

clearance of

the bearings

Item no.: 51198-5-9970 · Revision: 73287 · Print-out: 2012-04-11 · Y. Uhlmann (VM-TDO) · Page 12 / 12

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 7938 81-0 · Fax +49 7938 81-110 · [email protected] · www.ebmpapst.com