16

INM MTL 130-0126 Rev 13

5

CALIBRATION

5.1 General

The MTL katharometer based analysers are extremely stable instruments and require only

very occasional calibration. The exact calibration period depends on the type of sample and

environment the instrument is placed in. In practice it is unlikely that check periods of less

than one month would be necessary and three to six months would normally be in order. We

recommend that any quality assurance procedures written for the instrument are written to

allow verification as opposed to calibration. Verification involves checking that the instrument

provides the correct analysis of a standard gas within the limits of the instrument and only

calibrating when a result outside of limits is produced. The frequency of the verification would

need to be in line with the quality regime being operated by the user.

WARNING

The analogue output is set to 2mA (K1650) or 0v (K6050) while the instrument

is being calibrated. Ensure that any control loops that are connected to the

instrument are disabled prior to verifying or calibrating the instrument. Also

ensure that the process is in a safe state and the exhaust of the standard gas

is vented to a safe area. Calibration mode can only be entered by pressing the

Calibrate button for approximately 8 seconds whilst in Measurement Mode.

5.2 Piping

Ensure that the piping and connectors are of good quality with no possibility of leaks. Metal

piping is preferred as it is less prone to damage and sealing problems. Pressure regulators and

gauges that may be in the calibration gas lines all have a certain amount of dead space within

them and so may require purging for several minutes before the delivered gas matches that of

the cylinder contents. The regulator etc. may be connected to the instrument and the purge

monitored by using the instrument in measurement mode. Only when the reading is steady

has the dead space been purged.

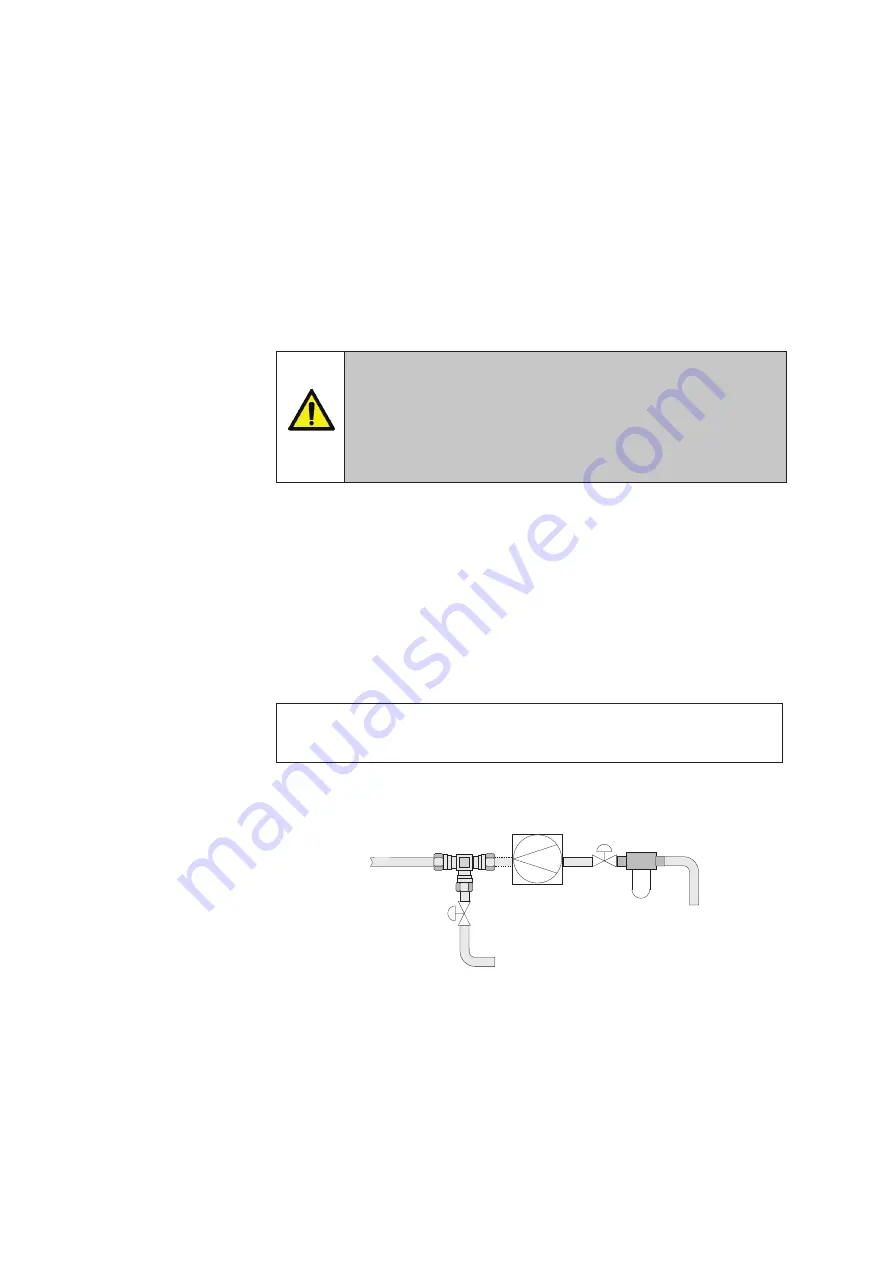

NOTE

For permanent installations (K1650) in may be convenient to include a ‘T’ piece and

appropriate valves in the sample inlet line so that the calibration gas is easily connected.

Figure 11

- Sample and calibration gas piping

Calibration

Gas Inlet

To Process

Sample Connection

To Sample Inlet

Filter

Shut-off

Valve

Pump

-if required

Shut-off

Valve