Installation, Operation and Parts Manual

EE-65A.40T

22

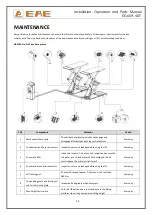

MAINTENANCE

Easy and low cost routine maintenance can ensure the lift work normally and safely. Following are requirements for routine

maintenance. You may decide the frequency of routine maintenance by consulting your lift’s actual working conditions.

GREASE: No.1 lithium base grease.

POS.

Components

Methods

Period

1

Mechanical safety catch

Check if both mechanical catches can engage and

disengage effectively by pushing control buttons.

Every day

2

Cylinders and oil hose connectors Inspect to ensure no leakage before using the lift.

Every day

3

Pneumatic filter

Listen and inspect if it leaks or not. Inspect and ensure the

the water level is below its max limit mark and the oil

level is above the minimum limit mark.

Every day

4

Pneumatic hoses and connectors

Inspect to ensure no leakage before using the lift.

Every day

5

Self-locking nut

Check with torque spanner. The torque is no less than

480N.m.

Every day

6

The padding plate and its support

rod for initial start plate

Inspect and add grease when necessary.

Every day

7

Max height limit switch

Push the UP button and inspect and ensure the lifting

platform stops rising at maximum lifting height.

Every day

Содержание EE-65A.40T

Страница 12: ...Installation Operation and Parts Manual EE 65A 40T 12 Surface mounting...

Страница 25: ...Installation Operation and Parts Manual EE 65A 40T 25...

Страница 26: ...Installation Operation and Parts Manual EE 65A 40T 26...

Страница 37: ......