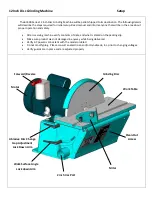

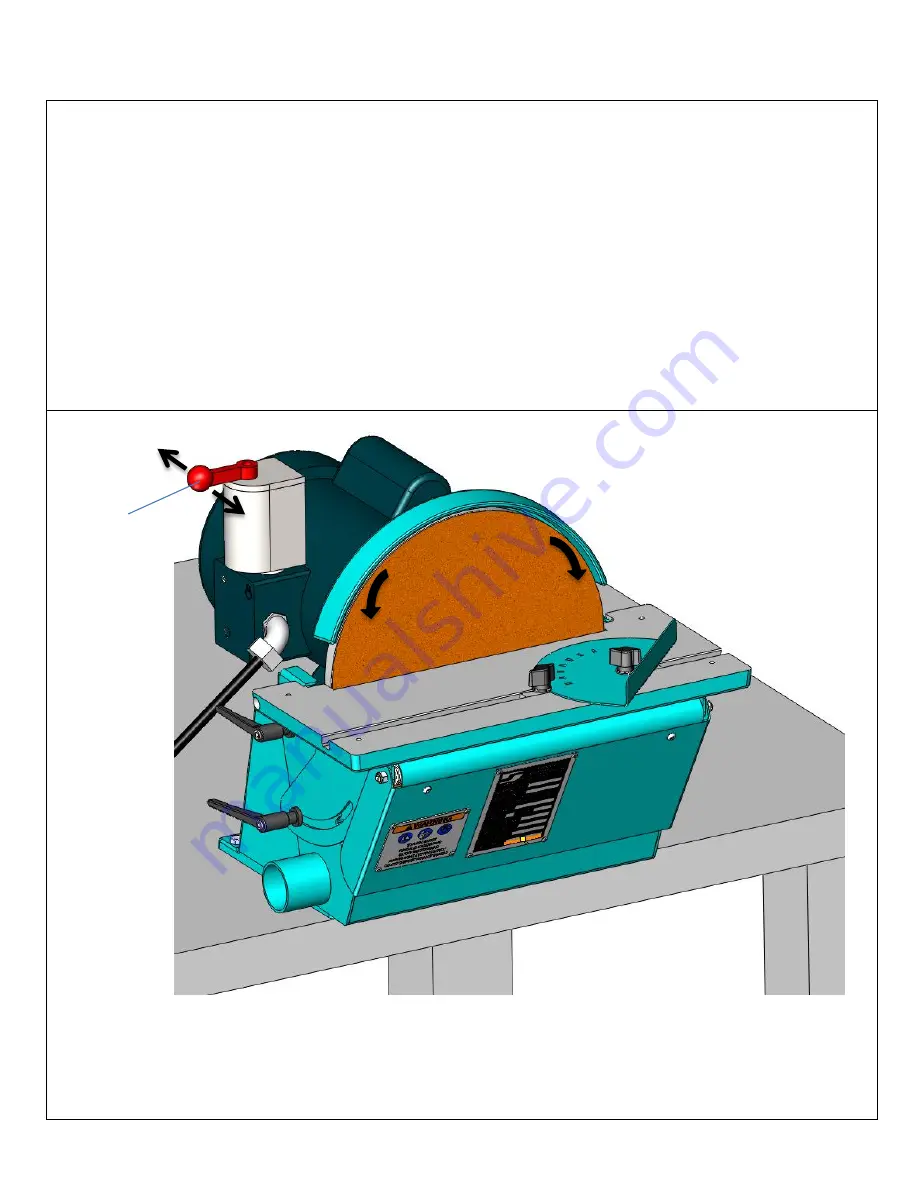

12 Inch Disc Grinding Machine Operation

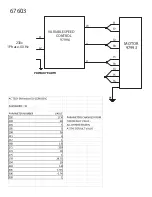

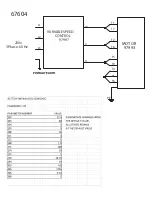

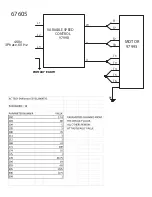

Engage the motor by placing the power lever in a forward or reverse position depending upon the desired

direction of wheel rotation.

Before switching direction of grinding wheel, be sure to move power lever to neutral position and allow grinding

wheel to come to a complete stop.

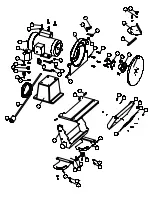

In the event that the grinding disc does not remain centered on the grinding wheel while machine is running and

in use, turn power off and fix before continuing to use. Re-center abrasive disc or trim overhanging abrasive.

*Note: A heat gun can be used to easily change your abrasive disc from one to the next. Apply heat evenly to the

disc from a 4” distance and periodically check for De-adhesion until the disc is easily removed. Continue by

cleaning any adhesive residue with an appropriate solvent before installing a new abrasive disc.

Reverse

Forward

Forward

Reverse

Power

Lever

Содержание 67600

Страница 16: ......