6

Dymax SG-200 High-Flow Spray Gun System User Guide

Overview of the Spray Gun System

How the Spray Gun System Works

The Dymax SG-200 spray gun system uses compressed air to pressurize the fluid reservoir. The pressure

pushes fluid from the reservoir through the fluid line to the handheld spray gun. A satellite controller is used

to control valve actuation. When you open the spray gun by squeezing the trigger, fluid flows into the spray

gun where it is atomized and sprays through the spray cap.

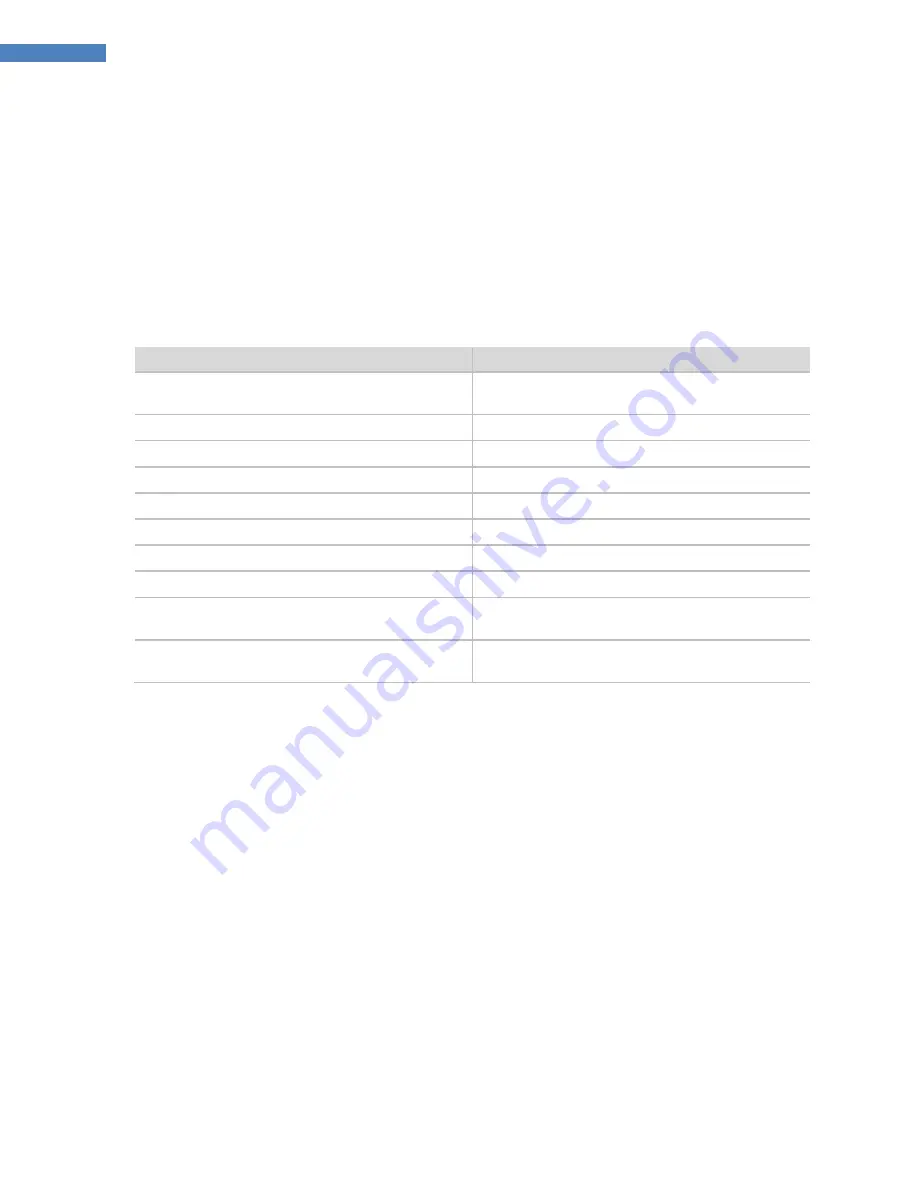

Special Features of the Spray Gun System

Features

Benefits

All wetted components on the spray gun are stainless

steel, Teflon®, or Kalrez®

Spray gun is compatible with a greater number of fluids

High-volume flow range of 2.5oz to 20oz per minute

Increased throughput for large part applications

Lightweight spray gun with low trigger resistance

Ergonomic design allows for hours of effortless spraying

Easy adjustment of material flow and spray atomization

Greater dispensing accuracy with less material waste

Pneumatically operated

No electrical power required

Sealed fluid body with no exposure to ambient conditions

Easy shutdown, material protection

Safety relief valves on bottle and pail reservoir tanks

Provides a safer system for users

Pail reservoir tanks manufactured from stainless steel

Compatible with a greater number of fluids

Air filter/regulator shutoff valve depressurizes system

when shutoff valve is closed

Provides a safer system for users

High-quality, air precision regulator supplied with three

pressure gauges (with different pressure ranges)

Ability to select the appropriate gauge for accurate

measurement and control of reservoir pressure

When replacing system parts, ensure the quality of replacement parts matches the quality of the original

equipment parts to maintain the safety and operational performance of the system.

Description of Main Components

Air Filter/Regulator

—

The air filter/regulator enables you to reduce the pressure of the plant incoming air to a

pressure useable by the dispensing system. The air filter/regulator includes:

a.

Filter bowl with coalescing filter to remove solid and fluid contaminants from the compressed air.

b.

Pressure gauge that displays the pressure of air after it is regulated.

c.

Pressure control knob that enables you to adjust the pressure of the air.

d.

Shutoff valve that enables you to start and stop the flow of air into the system. In the Closed position,

the shutoff valve also depressurizes the system by exhausting air through its exhaust port.

Air Precision Regulator

—

The air precision regulator enables you to precisely control the air pressure in the

fluid reservoir. The air precision regulator includes: