MAINTENANCE

SECTION 5

Page 47

DRESSTA

OM515C520C99/1E

5.15. SEAT BELT

WARNING! Do not use bleach, color dye or solvents on the seat belt webbing,

because this can weaken it and cause personal injury. Clean the seat belt only

with warm water and a mild detergent. Replace belts when worn, frayed, torn,

stiff, or rotted webbing or defects of the tang, buckle or anchors are detected.

Keep belt flat to avoid twisting and roping when not being used. Do not place heavy or sharp objects

on the belt.

The entire seat belt assembly should be inspected periodically for corrosion, wear, fraying or weak

spots. The seat belt mounting bolts should also be periodically inspected for looseness.

5.16. STEERING GEAR

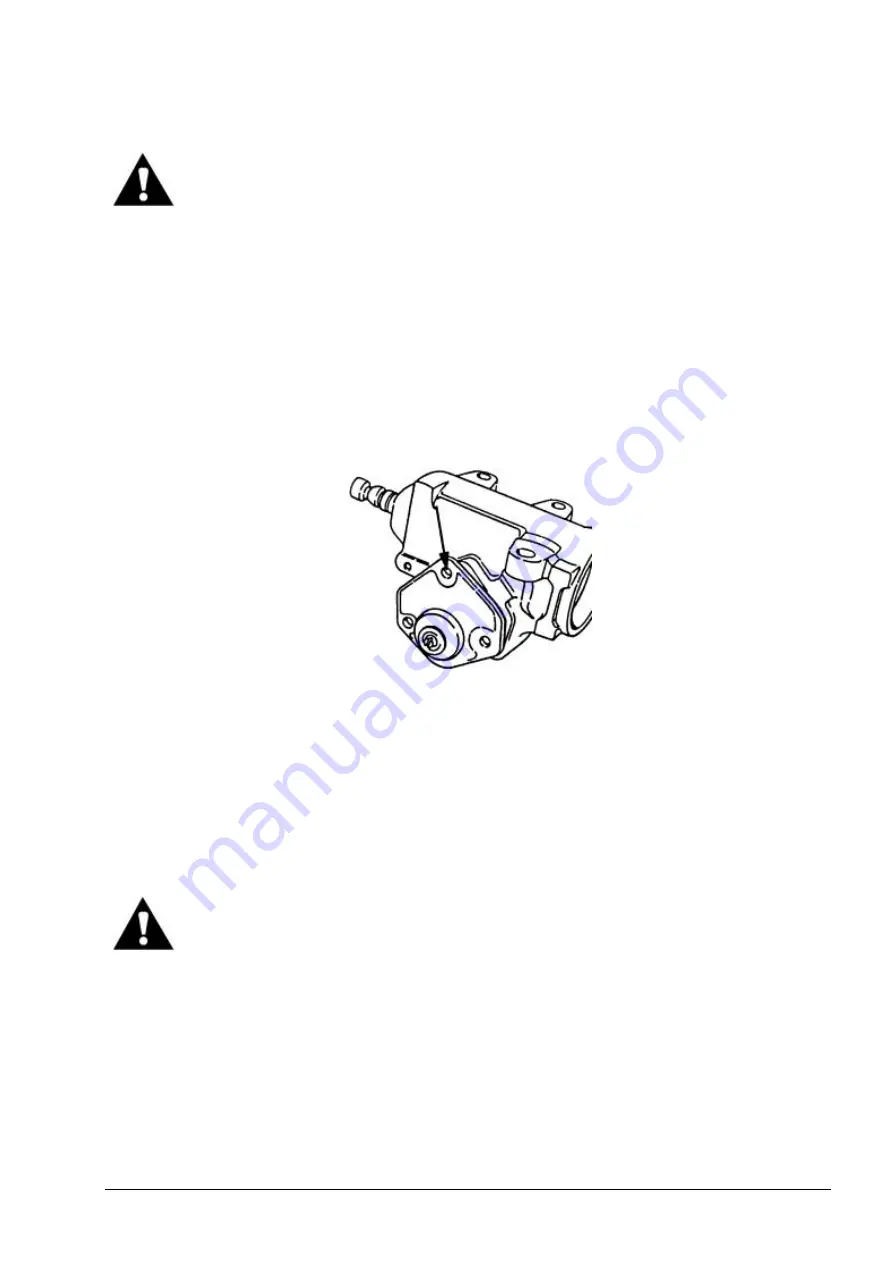

Check the lubricant level by removing the cap screw in the side cover (Fig. 5.39). If the lubricant is

below the cap screw hole add lubricant through the hole as necessary. Refer to Chart 2 and 3.

Fig. 5.39. Steering Gear Fill Location

5.17. TIRES AND RIMS

Avoid parking the machine in puddles of oil, grease or gasoline because this damages the tires.

INFLATION

WARNING! Never inflate a flat tire without inspecting the tire, rim and wheel for

damage. Be sure all components are properly assembled. Unmounted tires

being inflated or deflated should be placed in a tire safety cage. Inflate the tire

to 100 – 140 [kPa] and check that all components are properly seated. Then

continue to inflate to 240 – 280 [kPa]. Never stand directly in front of a tire and

rim assembly while inflating. Use a clip-on chuck with a hose long enough to

allow the person inflating the tire to stand to the side. Serious injury could result

if the tire and mounting were to separate.

PROPER INFLATION

Maintaining the proper air pressure provides maximum road contact and results in increased tire

life. Check inflation pressures with an accurate tire pressure gauge when the tires are cool. Be sure

to install valve caps after inflating a tire. Never vent built-up pressure in a tire, such as encountered

on hot days. Pressure build-up on hot days actually protects the tires by avoiding excessive

sidewall flexing and its overheating, which are detrimental to tire life. Venting tires will also result in

underinflation when the tires cool.

Содержание 515C

Страница 3: ...OM515C520C99 1E DRESSTA ...

Страница 5: ......

Страница 7: ......

Страница 10: ...SECTION 1 INTRODUCTION ...

Страница 11: ...INTRODUCTION SECTION 1 DRESSTA OM515C520C99 1E SECTION CONTENTS 1 1 Introduction 3 1 2 Serial Numbers 5 ...

Страница 12: ......

Страница 17: ...SECTION 2 SAFETY PRECAUTIONS ...

Страница 19: ......

Страница 37: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Страница 39: ......

Страница 49: ...SECTION 4 OPERATING ...

Страница 51: ......

Страница 55: ...SECTION 4 OPERATING Page 6 OM515C520C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Страница 107: ...SECTION 5 MAINTENANCE ...

Страница 165: ...SECTION 6 SPECIFICATIONS ...

Страница 167: ......

Страница 181: ...SECTION 6 SPECIFICATIONS Page 16 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...

Страница 182: ...SPECIFICATIONS SECTION 6 Page 17 DRESSTA OM515C520C99 1E WIRING DIAGRAMS ...

Страница 187: ...SECTION 6 SPECIFICATIONS Page 22 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...

Страница 192: ...SPECIFICATIONS SECTION 6 Page 27 DRESSTA OM515C520C99 1E SPECIFICATIONS Fig 6 10A Overall Dimensions Wheel Loader 520C ...